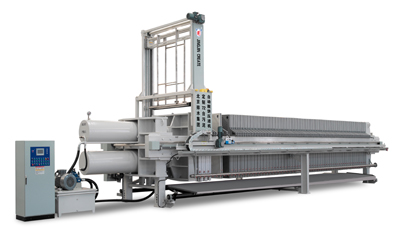

In various industries, filter presses are widely used to separate liquids and solids. They are essential equipment in industries such as food and beverage, chemical, pharmaceutical, and wastewater treatment. In this article, we will explore how filter presses are used in these industries and their benefits.

Application

What is a Filter Press and How Does it Work?

The guide explores the Filter Press, an essential tool for solid-liquid separation in various industries. Discover how does it works, with step-by-step processes, and its versatile applications. Learn about its benefits, from efficient separation to waste volume...

How to maintain the filter press

The maintenance of industrial filter presses involves a regular schedule of checks and procedures to ensure the proper functioning and longevity of the equipment. Maintenance tasks typically include: Cleaning of filter plates and filter cloths Lubrication of moving...

FAQ about filter presses

What are the factors that affect Filter Press filtration? The main factors affecting the dewatering efficiency of a filter press include Feed slurry solids percentage Slurry particle size distribution Chamber thickness Cake solids percentage Solid material...

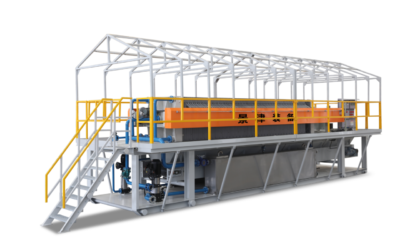

What is Industrial Wastewater & Where Does it Come From?

One of the most common by-products of industrial or commercial activities is industrial wastewater, which is the water used to make commercial products in nearly all phases of production across all industries. When this process water is used, it is considered waste...

How Does The Oil Filter Press Work?

Oil Filter Press Uses: High efficiency oil filter is designed for power plants, power stations, industrial and mining enterprises substation (room) lubricating oil depot, tractor station, petroleum, chemical industry, metallurgy, national defense industry and other...

Introduction of intelligent energy saving feed plunger pump

Intelligent energy saving feed pump (plunger pump) working principle plunger pump Jingjin intelligent energy saving feed plunger pump working principle Jingjin intelligent energy saving feed pump (plunger pump) is to rely on the plunger reciprocating movement in the...

FILTER CLOTHS FOR FILTER PRESSES

In cake-forming filtration, filter cloths are textile fabrics that separate the solids from a (chemically aggressive and tempered) suspension, allowing the solid-free filtrate to flow off. During the process, the filter cloths retain solids in layers while considering...