In the quest for the most effective water filtration systems, China's leading suppliers of sludge treatment equipment have emerged as pioneers in the field. With a focus on innovative technologies, these companies are revolutionizing the way wastewater is processed...

News

What is the Main Purpose of Water Filtration?

The water filtration machine is at the forefront of this innovation. It is an important tool that harnesses the power of advanced filtration methods to purify water. It is suitable for a wide range of applications, from household consumption to industrial processes....

How to Define Filter Press Accessory Part?

In the intricate landscape of industrial filtration, the filter press stands as a testament to engineering ingenuity. China Filter Press Accessory Part suppliers can provide us information. At the forefront of this technology, Filter Press Accessory...

How to improve the performance of the filter press in recycling

Rapid industrialization has brought challenges to wastewater management and minimizing environmental impact. In booming places like China, filter presses are key for industry moves like squashing filter cakes and cleaning wastewater. We're going to get into the...

Innovation in filter plate design and performance

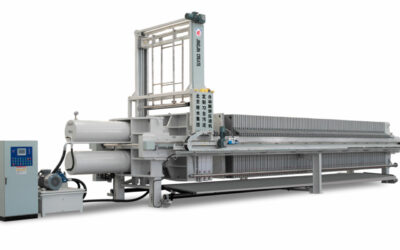

A filter press is a popular machine in industry, used for pulling solids out of liquids. The trick to how it does its job lies in a bunch of plates that are set up just right.We're going to look at the ins and outs of how the filter press plate do their thing, what...

A Deep Dive into the World of Filter Plates and Filter Presses

When it comes to industrial filtration, quality and new ideas are key, especially with filter plates and filter presses. Filter plates are used a lot in different industries, like chemical, pharma, food and drink, mining, and cleaning up wastewater. They help get rid...

China Cake Braiser can bring you great innovation

In the industrial processing and wastewater treatment sectors, efficient separation equipment is essential. Filter presses have become a foundational technology in the quest for efficient and environmentally sustainable industrial processes. This article focuses on...

Technical Advantages of Filter Presses

Filter press machines are the titans of liquid-solid separation, essential equipment for everyone from miners panning for gold to chefs preparing gourmet meals. Filter press machines work wonders by using enormous pressure to separate murky solids...

How to Choose the Right Filter Press

In the intricacies of industrial percolation, the humble filter cloth is the unsung hero that makes or breaks the entire manufacture. It’s more than just a piece of filter cloth, it’s the gatekeeper that determines what gets through and what gets left with during the...