Filter Press Cloth

The Press Filter is a highly efficient, mechanical device utilized in various industries for solid-liquid separation. It consists of a series of stacked filter plates or frames, alternating with filter cloths, that create a series of chambers when tightened together. Under pressure, liquid is forced through the filter cloths, leaving behind a solid residue or cake on the surface of the cloths. This process is effective in dewatering slurries, clarifying liquids, and recovering valuable solids from process streams.

We produce a wide range of high-quality filter cloths designed for use in various filtration applications, including filter press systems. They are specially engineered to provide superior filtration performance, ensuring efficient solid-liquid separation while maintaining high flow rates and clear filtrates. Whether you require woven, non-woven, or custom-designed filter cloths, we offer products that can be tailored to meet the specific needs of your filtration process. Our filter cloths are trusted across industries such as wastewater treatment, mining, food processing, and chemical engineering, ensuring reliability, long service life, and optimal filtration results.

The Filter Press is renowned for its ability to handle large volumes of material with high levels of solids recovery and minimal operational costs, making it an indispensable tool in mining, chemical processing, food and beverage production, wastewater treatment, and numerous other industrial applications.

The Filter Press, a versatile and essential piece of equipment in numerous industries, relies heavily on the quality and performance of its key component: the Filter Press Cloth. At Jingjin Filter Press, we understand the critical role that the filter cloth plays in ensuring efficient solid-liquid separation and optimal operational outcomes.

What materials are commonly used in the production of filter cloths?

Filter cloths are typically made from synthetic materials such as polypropylene (PP), polyester (PET), and nylon. These materials are chosen for their durability, resistance to chemicals, abrasion, and high temperatures. In some cases, fiberglass or PTFE (Teflon) may be used for specialized applications that require additional chemical resistance or high-temperature performance.

How to choose the right filter cloth for a specific filtration process?

Choosing the right filter cloth depends on several factors, including the type of slurry being filtered, the operating pressure, temperature, and the desired filtration efficiency. Key considerations include the material of the cloth, the porosity (mesh size), the fabric type (woven or nonwoven), and whether the cloth should have additional coatings or treatments (such as anti-static or hydrophobic coatings). The nature of the solid particles (size, shape, abrasiveness) and the desired clarity of the filtrate also influence the selection process.

How do filter cloths affect the filtration efficiency of a filter press?

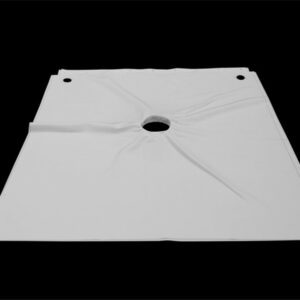

The filter cloth plays a crucial role in the filtration efficiency of a filter press. The material, porosity, and weave of the cloth determine how effectively it can separate solids from liquids. A cloth with the right pore size ensures that the filtration process is fast, efficient, and results in a clear filtrate. Additionally, the cloth’s surface texture and material affect cake release, which influences the ease of cleaning and the overall productivity of the filtration cycle.

How to prolong filter cloths’ lifespan?

Proper maintenance and cleaning of filter cloths are essential for extending their lifespan and maintaining filtration efficiency. After each filtration cycle, the cloth should be carefully cleaned to remove any residual cake and prevent clogging. This can be done using water, cleaning agents, or a combination of both, depending on the nature of the material being filtered. Regular inspection for signs of wear or damage (such as tears or loss of porosity) is also important. In some cases, filter cloths can be treated with special cleaning solutions or subjected to mechanical cleaning processes to restore their performance. Regular maintenance schedules and proper storage also help prevent premature degradation.

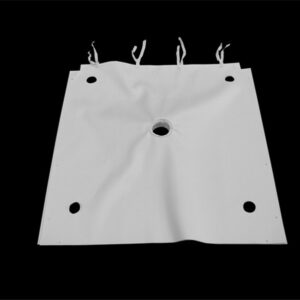

Our Filter Press Cloths, also known as filter fabrics, are specifically designed to withstand the rigorous demands of the filtration process. Made from high-quality materials such as polyester, polypropylene, or a blend of fibers, these cloths are engineered to offer superior filtration efficiency, durability, and resistance to wear and tear.

The filter cloth for the Jingjin Filter Press serves as the interface between the solid particles and the liquid being filtered. When the slurry is pressed between the filter plates under high pressure, the liquid permeates through the fine pores of the cloth, leaving behind a concentrated solid residue or cake on its surface. This process is crucial in industries like mining, where it helps to recover valuable minerals from ore slurries; in chemical processing, where it purifies raw materials and separates products; and in wastewater treatment, where it removes suspended solids and contaminants from water streams. The filter cloth for the filter press is a crucial element that ensures efficient solid-liquid separation, enhancing the overall performance and productivity of the filtration process.

About Jingjin

As a leading filter press cloth supplier, Jingjin Filter Press takes pride in offering a wide range of filter press fabrics tailored to meet the specific requirements of different applications. Whether you need a cloth that can withstand high temperatures, resist chemical attack, or achieve a particular level of filtration fineness, we have the expertise and resources to provide a solution that exceeds your expectations.

In addition to supplying top-quality filter press cloths, we also offer comprehensive support and guidance to our customers throughout the selection, installation, and maintenance process. Our team of experts is dedicated to ensuring that your Jingjin Filter Press operates at peak performance, maximizing the benefits of your investment and contributing to the success of your business.