In various industries, filter presses are widely used to separate liquids and solids. They are essential equipment in industries such as food and beverage, chemical, pharmaceutical, and wastewater treatment. In this article, we will explore how filter presses are used in these industries and their benefits.

What is a Filter Press and How Does it Work?

Related article: What is a Filter Press and How Does it Work?

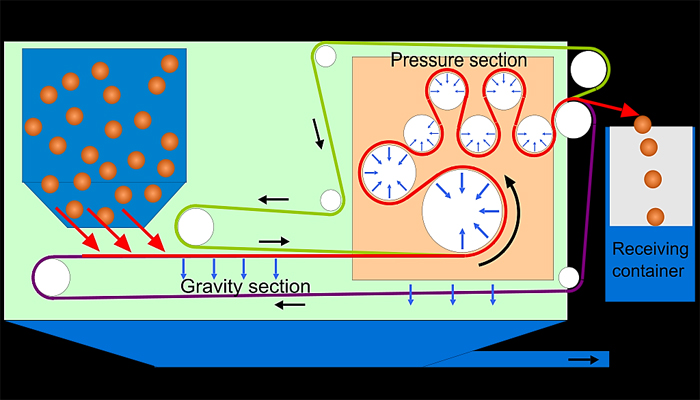

A filter press is a machine that uses a filter medium, such as a cloth or paper, to separate liquids and solids. The liquid is pumped into the filter press, and the solids are captured by the filter medium.

While the liquid passes through and is collected in a container. The filter press can be used for various applications, such as filtering liquids, clarifying liquids, and separating solids from liquids.

How Filter Presses are Used in the Food and Beverage Industry?

In the food and beverage industry, filter presses are used to filter liquids, such as fruit juice, milk, and beer. They are also used to separate solids from liquids.

Such as coffee grounds from the coffee liquid. The filter press helps to remove impurities and contaminants, ensuring the quality of the final product.

For example, a coffee company uses a filter press to separate coffee grounds from the coffee liquid. The coffee liquid is pumped into the filter press.

And the coffee grounds are captured by the filter medium. The filtered coffee liquid is then collected in a container and used for packaging.

How Filter Presses Are Used in the Chemical Industry?

In the chemical industry, filter presses are used to filter and separate chemicals. They are used to remove impurities and contaminants from chemicals, ensuring the quality of the final product.

For example, a chemical company uses a filter press to filter a chemical liquid. The liquid is pumped into the filter press, and the impurities are captured by the filter medium. The filtered liquid is then collected in a container and used for further processing.

How Filter Presses Are Used in the Pharmaceutical Industry?

In the pharmaceutical industry, these products are used to filter and separate pharmaceutical liquids. They are used to remove impurities and contaminants from pharmaceutical liquids, ensuring the quality of the final product.

For example, a pharmaceutical company uses a filter press to filter a pharmaceutical liquid. The liquid is pumped into the filter press, and the impurities are captured by the filter medium. The filtered liquid is then collected in a container and used for further processing.

How Filter Presses Are Used in the Wastewater Treatment Industry?

In the wastewater treatment industry, filter presses are used to separate solids and liquids from wastewater. They are used to remove impurities and contaminants from wastewater, ensuring the quality of the final product.

For example, a wastewater treatment plant uses a filter press to separate solids and liquids from wastewater. The wastewater is pumped into the filter press, and the solids are captured by the filter medium. The filtered liquid is then collected in a container and used for further processing.

Benefits of Using Filter Presses

Using filter presses in various industries has several benefits, including:

- Improved quality: These products help to remove impurities and contaminants, ensuring the quality of the final product.

- Increased efficiency: Filter presses are efficient machines that can filter large quantities of liquids quickly.

- Cost-effective: These products are cost-effective machines that can save money on labor and materials.

- Versatility: Filter presses can be used for various applications, such as filtering liquids, clarifying liquids, and separating solids from liquids.

Conclusion

In conclusion, filter presses are widely used in various industries, including food and beverage, chemical, pharmaceutical, and wastewater treatment.

They are essential equipment that helps to remove impurities and contaminants, ensuring the quality of the final product. Using filter presses has several benefits, including improved quality, increased efficiency, cost-effectiveness, and versatility.