Intelligent energy saving feed pump (plunger pump) working principle

Jingjin intelligent energy saving feed plunger pump working principle

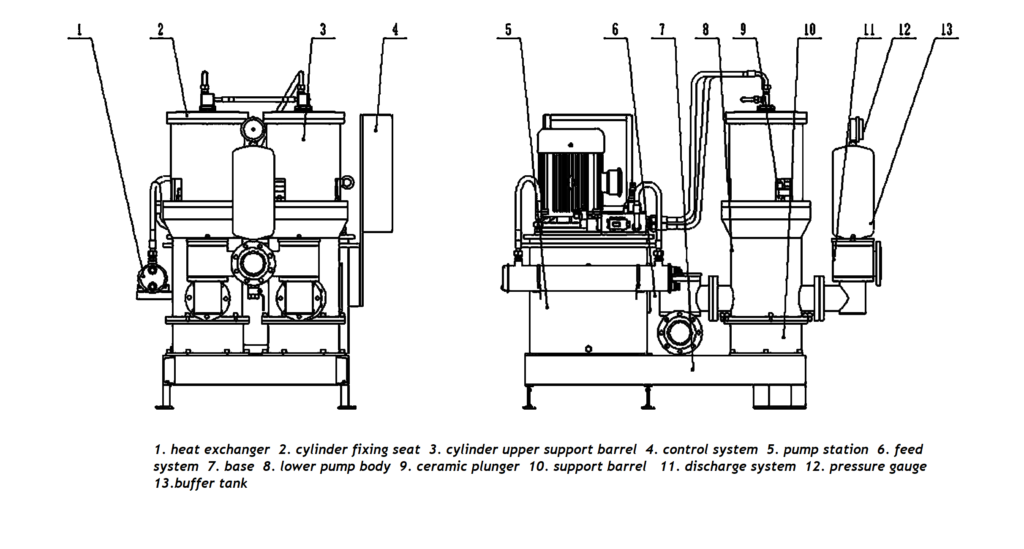

Jingjin intelligent energy saving feed pump (plunger pump) is to rely on the plunger reciprocating movement in the cylinder body, so that the volume of the sealed working chamber changes, then the suction and discharge of sludge can be achieved. The plunger pump has the advantages of high rated pressure, compact structure, no cutting to the running medium, convenient maintenance and self-adaptive of flow, energy-efficient, etc.

Intelligent energy saving feed pump (plunger pump) application

Jingjin intelligent energy saving feed pump (plunger pump) can output high pressure or even ultra high pressure transmission medium, has good self-lubrication, and less wear, with long service life and high efficiency, therefore the application scope is wide, it is suitable for high pressure,large flow filter press mud feed, slurry pipeline transportation, applied to the industry: mine, municipal, chemical, pharmaceutical, printing and dyeing, electroplating, etc., can also be used for long-distance transportation of mud, clean (dirty) water, coal slurry and other suspended solids, etc.,it is the ideal upgrade product to replace the screw pump.

Intelligent energy saving feed pump (plunger pump) features and innovative advantages

1. wear resistance

The plunger is alumina ceramic firing, after fine grinding, the hardness is HRC8.5 above, surface roughness 0.4uM. Plunger

and conveying material without shearing motion, and the effect for slurry with sand and solid particles is remarkable.

2. strong self-absorption ability

Plunger vacuuming mode, self-priming capacity 4-8 meters (the specific gravity of slurry determines the change of suction range).

3. compact structure

Adopt plunger cylinder built-in structure, the height is lower than the conventional vertical plunger pump. The cooling channel is built in, no leakage of internal circulating water, and the site is clean and tidy.

4. energy-efficient

Adopt large caliber, double cylinder hydraulic double pump design, and the required pressure is automatically switched according to the working condition of the filter press, to achieve the purpose of high efficient and energy saving.

5. intelligent control

Dynamic pressure acquisition, intelligent flow control, soft piston reversing, which greatly reduce vibration and noise, and ensure smooth operation.

6. simple operation

The pressure adjustment only needs to tighten or relax the pressure regulating valve.After adjusting the pressure, locking the valve, then it does not need to adjust again.

7. aesthetic appearance

The main body of the pump adopts sand blasting + spray painting process to eliminate the stress of the main body of the pump and ensure the adhesion and aesthetics of the anticorrosive paint.

8. safe and reliable

The pump is equipped with safety pressure sensor, temperature overheat protection sensor and action timeout alarm to ensure the safe use of the pump.

9. premium brand of electrical components

The low-voltage electrical components in the cabinet are Schneider brand, and the PLC is Siemens brand.

10. intelligent control

There are remote and local control. Local control is started locally on the control cabinet of the plunger pump. Remote control can communicate with the filter press control cabinet or upper computer through hard wiring, MODBUS or Ethernet, remotely start the plunger pump, and then read the running state of the plunger pump.

11. high rated pressure

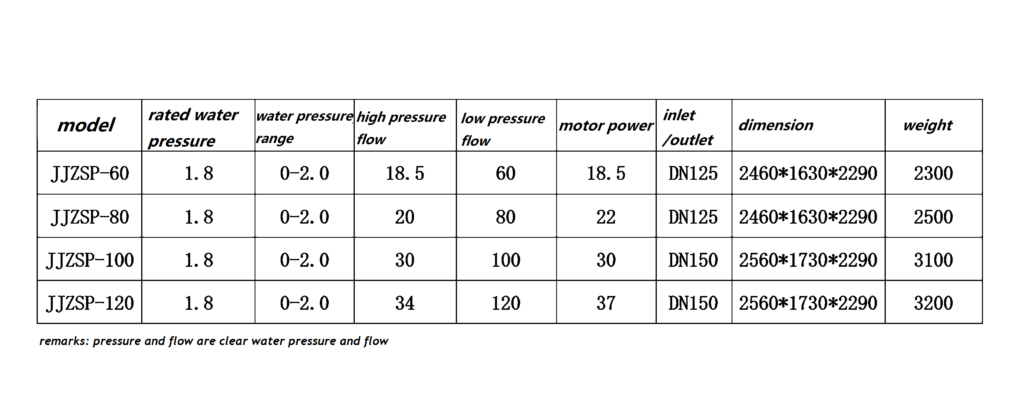

Feed pressure range 0-2.0mpa (2.0mpa-3.5mpa should be specified), rated water pressure up to 1.8mpa.

12. perfect match with process requirements of each phase for filter press feeding

Initial feeding stage: at this time, the chamber of the filter press is empty, and the slurry needs to be filled quickly. at this time, the hydraulic pumps with large and small displacement are opened at the same time to reach the maximum flow value.

Boost pressure and filter stage: when the filter press is filled with slurry, pressure begin to rise, and the filter press quickly discharge filtrate, and with the increase of pressure in the chamber, the feeding pressure of the plunger pump begins to rise gradually. at this time, the plunger pump automatically switches to the operation of the large-displacement hydraulic pump according to the pressure, and the small-displacement hydraulic pump stops, so as to meet the feeding requirements of medium-high pressure and large flow at this stage.

Pressure holding filtration stage: the feed pressure of the filter press rises to the highest set pressure, and the feed pressure needs to keep constant pressure filtration. at this time, the plunger pump automatically switches to the operation of small displacement hydraulic pump according to the pressure, so as to save energy, and the flow becomes the minimum and meet the demand of pressure holding.

13. low cost of use

The vulnerable parts of the pump are the valve plate and the plunger seal, and the replacement cycle of ceramic mud is once every 3-6 months, and for municipal sludge it is 6-12 months.

14. long service life

The plunger pump can be used for at least 15 years.

Customized production: according to the actual working conditions of each user, the product will be flexibly configured, and customized to be suitable for each customer’s production needs.

Parameter list

Related Products: