In cake-forming filtration, filter cloths are textile fabrics that separate the solids from a (chemically aggressive and tempered) suspension, allowing the solid-free filtrate to flow off. During the process, the filter cloths retain solids in layers while considering the process characteristics. It is through accumulating layers of the solids that the filter cake is built. The pore size or mesh width is one of the parameters for the degree of filter efficiency. The strength of the filter fabric must transfer the force resulting from the filtration pressure to the filter support. However, the longer these cloths are used, the more solids are also deposited in the fabric structure and clog this structure. As a result, the permeability of liquids is reduced. Heavily soiled filter cloths require cleaning because the filtration time is extended, the service life of the filter cloth is shortened and the cake release behavior deteriorates.

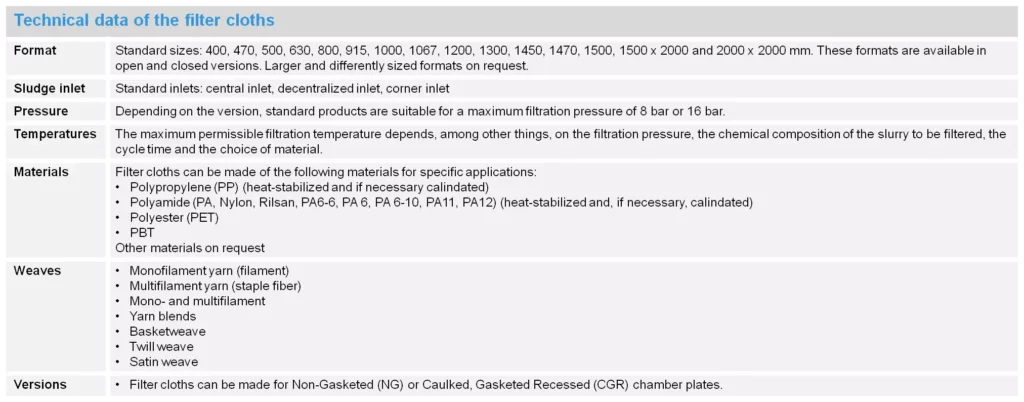

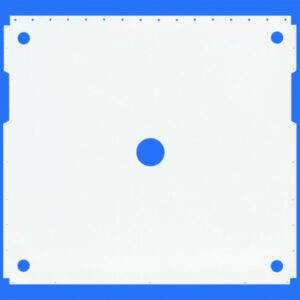

Depending on the application, the filter cloth edges can consist of fabric edges, e.g. felt, one-sided edge sealing (EPR), or only filter cloth. Filter plates and filter cloths in drip-proof design (CGR) are available to seal a plate pack to the outside. The filter plates seal against each other with O-rings. The filter cloths, on the other hand, have a circumferential clamping cord sewn into them and are clamped into a groove within the O-ring seal. Filter cloths for the head and end plates are single-layer cloths. The central outlet opening on the head plate filter cloth is cut out, the filter cloth for the end plate, in contrast, does not have an opening for the turbidity inflow.

Depending on the application and field of application, there are filter cloths with different permeabilities, structures, designs (overhang filter cloth, push-through filter cloth, CGR), and materials.

TEXTILE TECHNOLOGY

A comprehensive range of fabrics, including monofilament and multifilament yarns, monofilament and multifilament yarn blends, multifilament staple fiber blends, and other innovative products, is specially designed for filter presses. Polymers such as polypropylene (PP), polyamide (PA, Nylon, Rilsan, PA6-6, PA 6, PA 6-10, PA11, PA12), polyester (PET), and PBT are used in this range. In particular, all chemical requirements have to be met with high particle retention, optimum in terms of flow rate, moisture content, and cake-washing properties. In this context, the calendared filter media achieve a sufficiently smooth surface for simplified cake separation. In addition, proper thermosetting ensures dimensional accuracy.

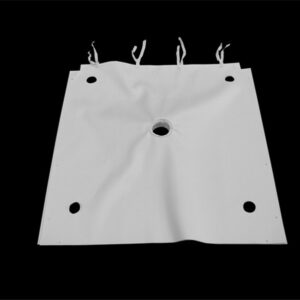

TECHNICAL DETAILS