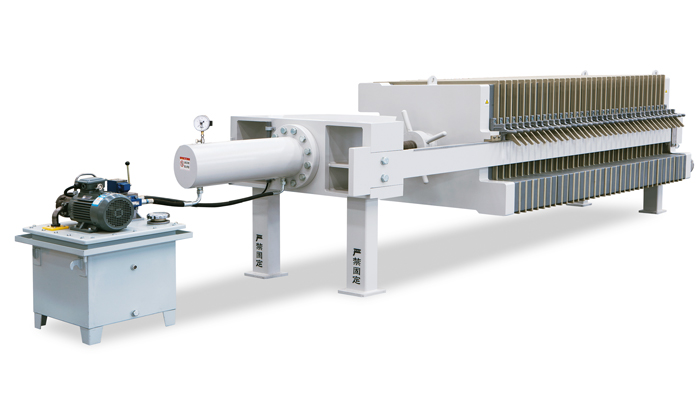

A filter press is a versatile and widely used equipment in various industries, such as chemical, and food. In this article, we will explore the working principle of a filter press and its applications.

Press filters are used to remove impurities and contaminants from liquids, such as water, oil, and other liquids. They work by applying pressure to the liquid, which causes the impurities to settle at the bottom of the container. The liquid is then removed from the container, leaving behind the clean liquid.

Filter Press Working Principle

The working principle of a filter press is based on the principle of gravity. The press consists of a series of chambers, each with a different level of pressure. The liquid to be filtered is placed in the first chamber, where it is subjected to a certain amount of pressure.

As the liquid flows through the press, it is forced downwards through a series of channels, where it is subjected to additional pressure. The liquid then passes through a series of filters, which remove any remaining impurities. Finally, the clean liquid is collected in the last chamber.

How Does a Filter Press Work?

To understand how a filter press works, let’s consider an example. Imagine you have a bucket of dirty water that you want to clean. You could pour the water into a filter press, which would apply pressure to the water, causing the impurities to settle at the bottom of the container. The clean water would then be collected in the last chamber of the press.

The process of filtering the water through the press is similar to the way that a coffee filter works. The coffee grounds are placed in a paper filter, and the coffee is poured through the filter, removing the grounds and leaving behind the clean coffee.

Advantages of Using a Filter Press

Using a filter press has several advantages. First, it allows for the removal of impurities and contaminants from liquids, resulting in cleaner and safer products. Second, it is a cost-effective solution, as it eliminates the need for manual filtration. Third, it is easy to maintain and operate, as it requires minimal maintenance and does not require specialized training.

Examples of Filter Press Applications

Filter presses are used in a variety of industries, including:

- Water treatment: Filter presses are used to remove impurities and contaminants from water, such as sediment, bacteria, and viruses.

- Oil refining: Filter presses are used to remove impurities and contaminants from oil, such as sand, dirt, and other particles.

- Chemical processing: Filter presses are used to remove impurities and contaminants from chemicals, such as heavy metals and organic compounds.

- Food and beverage processing: Filter presses are used to remove impurities and contaminants from food and beverages, such as bacteria, viruses, and other microorganisms.

Conclusion

In conclusion, filter presses are an essential tool in many industries, as they allow for the removal of impurities and contaminants from liquids. By understanding the working principle of a filter press, we can appreciate the importance of this technology and the many ways in which it is used to improve the safety and quality of our products.