Discover the inner workings of filter presses and their significance in industrial applications. This comprehensive guide explores the principles, processes, and benefits of the filter press working principle. Gain a clear understanding of how filter presses separate liquids and solids efficiently. Whether you’re a professional or a curious reader, this article offers valuable insights into this essential industrial equipment.

In this comprehensive guide, we will delve into the functioning of filter presses and their crucial role in various industries. From their basic principles to the filter press working operational processes, we will explore how filter presses efficiently separate liquids and solids. Whether you’re a professional or simply curious about filter press working, this article will provide valuable insights. Let’s dive in!

Understanding Filter Press Principles

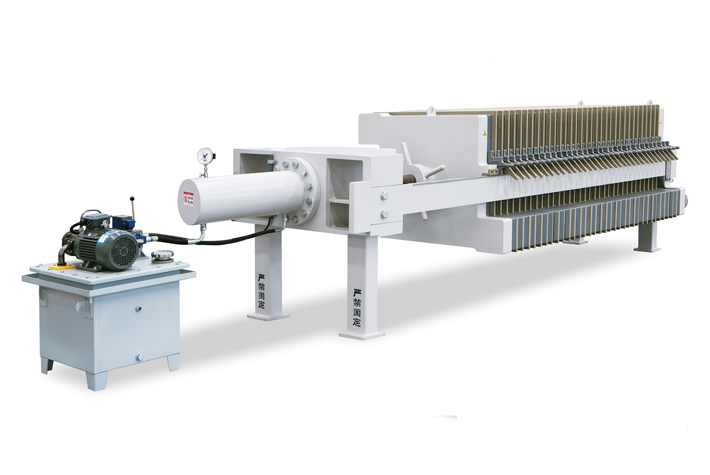

Filter presses operate based on the principle of pressure-driven filtration. They consist of a series of chambers containing filter plates with filter cloths. The process begins with the slurry, a mixture of liquid and solid, being pumped into the press.

Operating Process of Filter Presses

Next, the filter plates are compressed together using hydraulic or mechanical systems, creating a sealed environment. This pressure forces the liquid to pass through the filter cloth while retaining the solid particles. The separated liquid, known as filtrate, is collected for further processing or disposal.

Significance of Filter Press Working

Filter presses are vital in various industries, including wastewater treatment, mining, chemical manufacturing, and pharmaceuticals. They effectively remove impurities, clarify liquids, and recover valuable substances. The ability to handle large volumes of slurry and achieve high levels of solid-liquid separation makes filter presses indispensable in many industrial processes.

Benefits of Filter Press Working

The filter press working principle offers numerous advantages for industrial applications. Firstly, it ensures efficient solid-liquid separation, resulting in drier filter cakes and cleaner filtrate. Additionally, filter presses have a relatively low operating cost, are easy to maintain, and offer high automation potential. They are versatile and can be customized to suit specific process requirements.

Example: Wastewater Treatment

One practical example of filter press usage is in wastewater treatment plants. Filter presses effectively remove solid particles, such as sludge, from wastewater, allowing for the safe disposal or reuse of the treated water. This process reduces environmental impact, supports regulatory compliance, and promotes sustainable practices.

Conclusion

In conclusion, understanding filter press working is crucial for professionals across various industries. Filter presses provide efficient solid-liquid separation, contributing to cleaner filtrate and drier filter cakes. With their versatility and customizable features, they are indispensable in industrial processes such as wastewater treatment, mining, and chemical manufacturing. By incorporating filter presses, businesses can improve operational efficiency, reduce environmental impact, and achieve regulatory compliance.