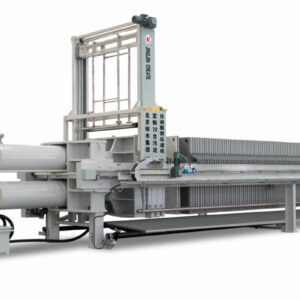

sludge filter press

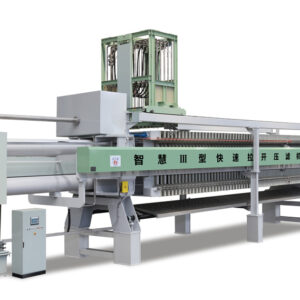

- The material of the Jingjin frame is Q345B, which makes our machine can be operated more safe and stable.

- The oil cylinder seat, pressing plate, and thrust plate are formed by carbon dioxide protection welding.

- The main beam of the Jingjin filter press is designed by adopting welded box construction.

- All the spare parts that need painting are dealt with high-speed centrifugal ball blast descaling and iron scale.

Product Description

Sludge Filter Press-Established Manufacturer

A sludge filter press is a specialized piece of equipment designed to separate solids from liquids in sludge, which is a semi-solid mixture typically generated from various industrial, municipal, and wastewater treatment processes. The primary purpose of a sludge filter press is to dewater the sludge, reducing its volume and producing a more manageable solid cake for disposal or further processing.

This product is likely equipped with advanced dewatering technology. These technologies help effectively separate solid particles from sludge, resulting in drier solids and more water removal. This is crucial for reducing sludge volume and facilitating proper disposal or reuse.

Main Features of a Sludge Filter Press

- Plate Configuration:

Sludge filter presses consist of a series of filter plates arranged alternately with frames. The leaves have filter media that allow liquid to pass through while retaining solids. - Filter Media:

High-quality filter media are used to ensure efficient separation of solids from liquids. The choice of filter media depends on the sludge’s characteristics. - Hydraulic or Mechanical Compression:

The filter press employs hydraulic or mechanical systems to apply pressure to the plates, compressing the filter cake and expelling excess water. - Automatic or Manual Operation:

Filter presses can be operated manually or automatically, depending on the complexity of the equipment and the desired level of control. - Filtration Efficiency:

A well-designed sludge filter press ensures effective separation and dewatering, producing a high-quality cake with reduced moisture content. - Control Systems:

Advanced sludge filter presses may feature automation and control systems that allow for precise control of the filtration and dewatering process. - Chemical Additions:

Some sludge filter presses incorporate the use of flocculants or other chemical additives to aid in sludge conditioning and aggregation.

Applications of Sludge Filter Press

- Municipal Wastewater Treatment

- Industrial Wastewater Treatment

- Mining and Mineral Processing

- Chemical Processing

Why you will choose our products?

- Innovation and Technology:

Jingjin Filter Press has efforts to stay competitive and provide advanced filtration solutions. This can include advancements in filter media, automation, energy efficiency, and process optimization. - Quality and Manufacturing:

Jingjin has established quality control processes and manufacturing standards to ensure the reliability and durability of its filter presses. Their reputation for delivering well-constructed and high-performance filtration equipment contributes to their brand strength. - Global Presence:

Jingjin Filter Press has expanded its reach beyond China, establishing a global presence through distribution networks, subsidiaries, or partnerships, it indicates a broader recognition and acceptance of its products on the international stage. - Customer Satisfaction and Support:

Customer feedback, reviews, and testimonials play a crucial role in establishing brand strength. Brands that prioritize customer satisfaction and offer excellent after-sales support tend to build stronger reputations. - Industry Certifications and Compliance:

Jingjin Filter Press adheres to industry-specific guidelines and holds certifications for quality, safety, and environmental standards, it adds to its credibility.