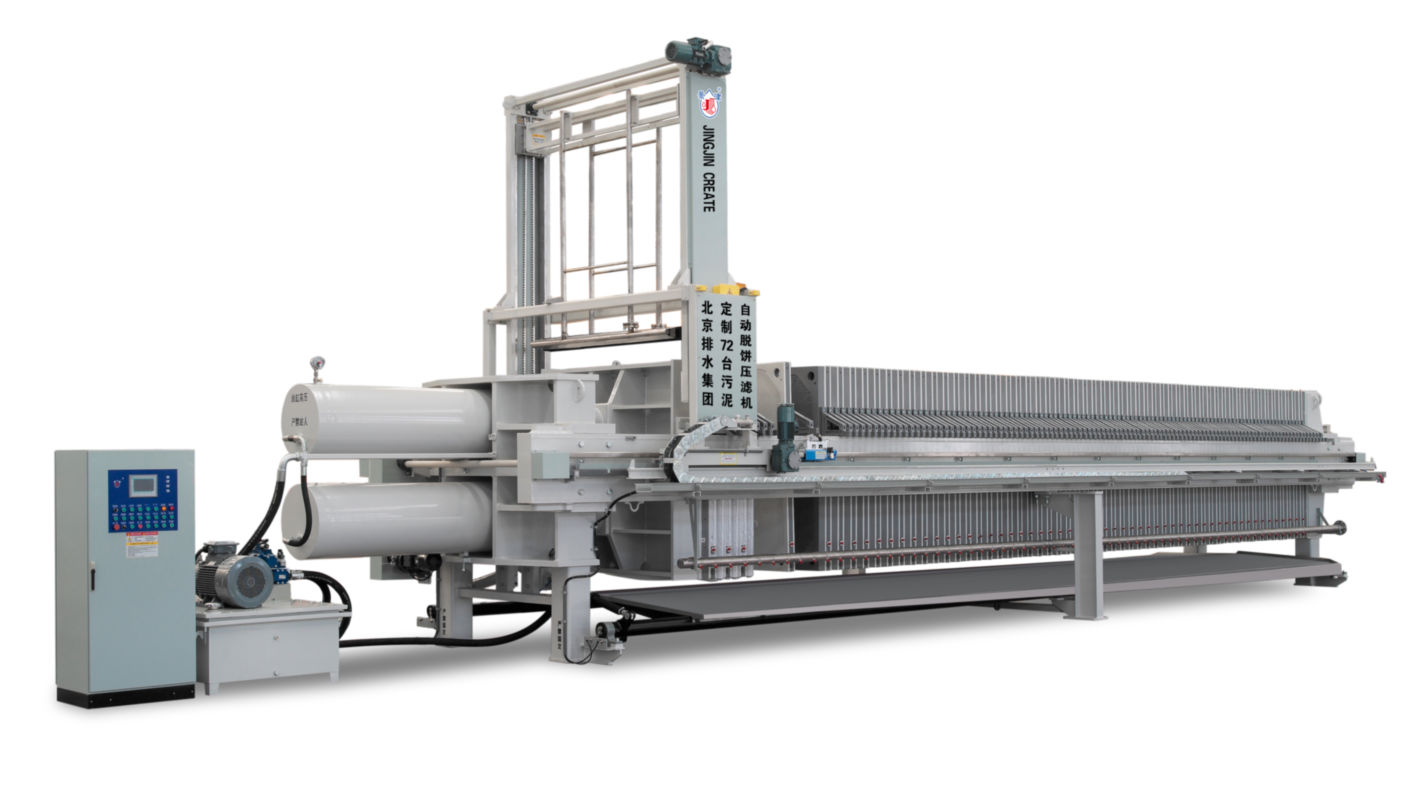

Product Description

What is a Membrane filter press

Membrane filter press is a filter press with an elastic membrane installed between the filter plate and the filter cloth. During use, when the feeding is finished, high-pressure fluid or gaseous medium can be injected into the diaphragm plate. At this time, the entire diaphragm will bulge and press the filter cake to achieve further dehydration of the filter cake, which is usually called squeeze filtration.

Membrane filter pressApplication

Membrane filter press has the advantages of high pressing pressure, good corrosion resistance, convenient maintenance, safety and reliability, etc. It is the first choice for customers in metallurgy, gas, papermaking, coking, pharmacy, food, brewing, fine chemicals and other industries.

Membrane filter presses have been widely used in various fields that require solid-liquid separation. Diaphragm filter press is considered to be an alternative upgrade equipment for ordinary chamber filter press.

Membrane filter presses have shown good results in terms of processing capacity per unit area, reduction of filter cake moisture, and adaptability to the properties of the processed materials.

Membrane filter press vs ordinary chamber filter press

The main difference between the membrane filter press and the ordinary chamber filter press is that two elastic membranes are installed on both sides of the filter plate (the composite rubber diaphragm is an integral diaphragm). During operation, when the feeding is completed, The high-pressure fluid medium can be injected into the diaphragm plate. At this time, the entire diaphragm will bulge and press the filter cake to achieve further dehydration of the filter cake, which is squeeze filtration.

Diaphragm filter press is used in sludge and sewage treatment. The lowest water content of the filter cake has been below 60%. Compared with the traditional chamber filter press, the highest solid content of the filter cake can be increased by more than 2 times. The cost of filter cake transportation Greatly reduced, the filter cake can be directly burned in the power plant, truly turning sludge into resources and sewage into clear springs, completely replacing the van filter press.

Due to its excellent filtration effect, membrane filter presses have proven themselves in many applications, such as in the mining, chemical or pharmaceutical industries. In order to meet the different requirements of industry and municipal administration, JingJin membrane filter press adopts modular design similar to box filter press.

The strong and durable steel filter press frame is composed of the following main components to form the foundation: a feed table with a filtrate outlet (head piece), a hydraulic table with a locking cylinder (press block), a beam and a separate membrane for the side rails The filter plate includes filter cloth. The plate pack consists of a uniform membrane plate with a 15-50 mm cutout (the mixing chamber membrane filter plate is also optional) to accommodate the puncture-resistant filter cake. The standard membrane materials used are polypropylene (PP), synthetic rubber (such as NBR, EPDM) or thermoplastic elastomer (TPE). Special materials such as PVDF are also available.

Membrane filter presses technology

Membrane filter presses have a great influence on the dryness of solids by using membrane technology in the filter plate. Compared with the traditional filtration process, it achieves the lowest residual moisture value in the filter cake. This makes the membrane filter press the most powerful and widely used system. Special materials such as PVDF are also available. Membrane filter presses have a great influence on the dryness of solids by using membrane technology in the filter plate. Compared with the traditional filtration process, it achieves the lowest residual moisture value in the filter cake.

This makes the membrane filter press the most powerful and widely used system. Special materials such as PVDF are also available. Membrane filter presses have a great influence on the dryness of solids by using membrane technology in the filter plate. Compared with the traditional filtration process, it achieves the lowest residual moisture value in the filter cake. This makes the membrane filter press the most powerful and widely used system.

The filer press can be used in many industries

Such as: Filter press application range:

Chemical: dyes, pigments, caustic soda, soda ash, alkali salt mud, white carbon black, saponin, graphite powder, bleaching powder, stand, phosphor, potassium chlorate, potassium sulfate, ferrous sulfate, copper sulfate, silver sulfate, barium sulfate, ferric oxide, water purifier (aluminium sulphate and polyaluminium chloride, basic aluminum chloride)

Medicine: antibiotics (aureomycin, erythromycin, spiramycin, validamycin, midecamycin, tetracycline, berberine, terramycin) phytic acid calcium, traditional Chinese medicine (TCM), alcohol and growth derived yarn, organophosphorus, saccharifying enzyme.

Food: rice wine, white wine, fruit juice, beverage, beer, yeast, citric acid, plant protein, plant sweet element, glucose, malt sugar, stevia sugar, malt sugar, starch, sugar, starch, rice flour, corn starch, liquid glue, monosodium glutamate, spices, sauce, oral liquid, soy milk, algae.

Metallurgy: gold, silver, copper, iron, zinc, rare earth powder processing, etc.

Refining: white oil, sesame oil, light oil, glycerin, machine oil, vegetable oil.

Clay: old soil, bentonite, activated soil, China clay, electronic ceramic soil.

Membrane filter press Quick Details

Membrane filter press Supply Ability

Supply Ability:10000 Set/Sets per Year

Packaging & Delivery

Port:Tianjin , Qingdao

Membrane filter press manufacturer – Company Information

Jingjin Environmental Protection Inc. founded in 1998.The company is a complex environmental protection service provider of filter outfit production, filter technology overall plan solution and environment protection project contraction and operation.It is also the vice-president unit of China Environmental Protection industry Association and the primary drafter of national standards for filter press and filer plates.The filter press’s production capacity and sales volume remain the largest worldwide for twelve consecutive years, and sells to 123 countries and regions.Jingjin trademark has been recognized as a ‘Famous Chinese Trademark’ by the State Administration for industry and Commerce of China, and is also protected by Madrid International Trademark Rgistration.Water Jiang, chairman of Jingjin was awarded National Labor Model and National Model Worker,

JIngjin is devoted into the development of energy conservation and environment protection career , providing consumers by cost-effective products and professional quality service. In order to achieve better filtering requirements, Jingjin introduced a complete set of German filter cloth production line and tehnology.By virtue of jingjin’s 27 years of filtering experiende, the heavy German rapier looms weave the thinnest silk threads into filter cloth of high density and different hole patterns by using 0.3-3.5 tons beating-up force after each weft across warp. Under same area the filtration holes of JIngjin filter cloth are 50% more than other iflter cloth, which improve the filtration speed greatly.The filter cloth was woven under constant temperature and humidity ,which eliminate the fabric burrs caused by static electricity.

What’s the most important is that monofilament flter cloth can make the filter cakes fall off automatically, which has conquered the unsolved problem ever since.

While practicing its China dream, Jingjin is trying its best to become the most influential complex service provider in environmental protection area worldwide, with its mission of “Protectiing Environment and Besutifying China” and its green strategy of “Turning sewage into pure water and sludge into resource”, providing profound answer for eco-environment protection and economic development, leaving clean water and blue sky to our descendants.

Your smile is our commitment! Jingjin will alwasys be your best friend!