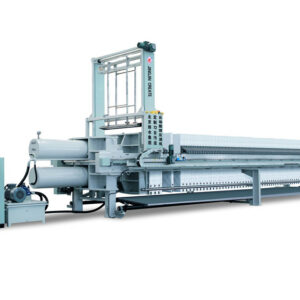

Screw Press Dewatering Equipment

- Individual adaptation to fulfill different process requirements and specific customer requirements

- The high degree of configuration and maximum flexibility

- Compact and robust design for a flawless and reliable filtration operation

- High level of security through the use of the latest security techniques

- Good price/performance ratio

Product Description

Screw Press Dewatering Equipment-employed in wastewater treatment

Screw press dewatering equipment is mechanical separation equipment popular to remove water from solid materials. Particularly sludge or other waste products. It is commonly employed in wastewater treatment, industrial processes, and various applications where efficient dewatering is required.

The equipment uses a rotating screw or auger inside a cylindrical screen or drum to gradually compress and squeeze out the liquid content from the solids. Screw press dewatering equipment is popular in municipal wastewater treatment plants and industrial facilities.

Agricultural operations, and other settings where sludge or wet waste materials need to be efficiently dewatered before disposal or further processing. The specific design and capacity of screw presses can vary depending on the application and the characteristics of the material being processed.

Benefits & Features

- Enclosed to minimize odors and noise

- Shallow wash water usage(1/8 compared with belt press)

- Very low power consumption(1/20 compared with a centrifuge)

- High cake solids

- Minimal operator requirement

- Easy to operate and maintain

- Auto start-up, run, and shutdown

- Touchscreen operation optional

- Sludge Flow and Cake Monitoring System

- Available with many other options like Dairy, Palm Oil, etc.

How Does It Work?

- Force & water concurrent

The force and water work in the same direction to make the free water separate at the fastest speed. - Moderate pressure

Maintain the lowest energy consumption and mechanical wear while ensuring the sludge dewatering is effective, - Thin-layer dewatering

Dewatering with a thin layer makes the free water separated at the fastest speed. - Extension of the dewatering path

To allow enough time and continuous operation in dewatering.