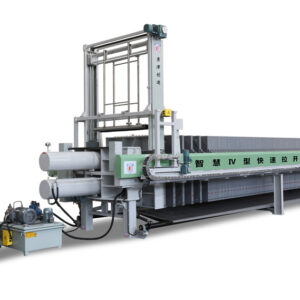

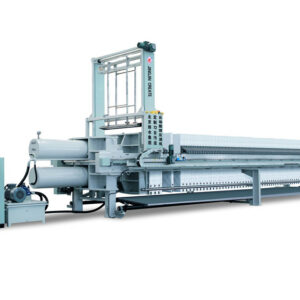

Product Description

Membrane Filter Press-used in various industries

A membrane filter press is a type of filter press popular in various industries and processes for solid-liquid separation. It is an advanced and specialized variation of the traditional filter press that incorporates a flexible or elastic membrane into the filter chamber. This membrane can be made of various materials, including rubber or elastomers.

Membrane filter presses are used in a wide range of industries, including wastewater treatment, chemical processing, mining, pharmaceuticals, food and beverage, and many others where solid-liquid separation is required with high efficiency and reduced environmental impact. Greatly improved the overall efficiency of industrial production.

How Does a Membrane Filter Press Work?

- Charging the Filter Chamber

- Initial Filtration

- Membrane Inflation

- Enhanced Dewatering

- Final Filtration

- Cake Discharge

Key Advantages of Membrane Filter Presses:

- Higher Filtration Efficiency:

Membrane filter presses achieve higher cake dryness compared to traditional filter presses, reducing the amount of liquid waste generated. - Shorter Cycle Times:

The addition of the membrane squeezing stage accelerates the filtration process, resulting in quicker cycle times and increased productivity. - Improved Cake Quality:

The membrane helps produce a more uniform and consistent filter cake, which can be easier to handle and dispose of. - Reduced Environmental Impact:

By producing drier filter cakes and reducing the volume of liquid waste, membrane filter presses can minimize the environmental impact of filtration processes.