Product Description

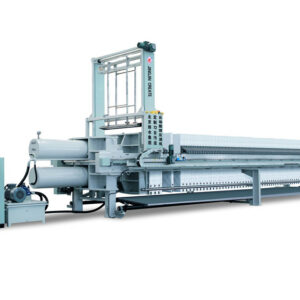

Concept Of Tubular Filter Press?

A tubular filter press is a type of sludge dewatering equipment that uses a cylindrical horizontal design. It consists of a series of tubes with filter cloths inside that are arranged horizontally in a frame. Sludge is fed into the tubes and pressure is applied from the outside to squeeze water out through the filter cloth, leaving a dewatered sludge cake.

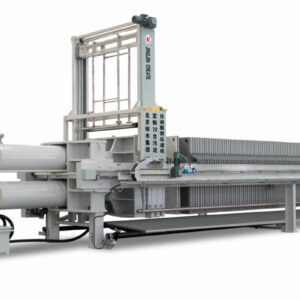

Tubular Filter Press China Manufactuer

- Established in 1998, Jinjiang Environmental Protection Inc. aims to be a one-stop-shop for environmental protection services. The company provides a range of solutions, including manufacturing filter equipment, integrated filtration technology, and contracting and managing environmental protection projects.

- Additionally, the company serves as the vice-president unit of China Environmental Protection industry Association and is the main drafter of national standards for filter press and filer plates.

- The company’s filter press production capacity and sales volume have remained the largest in the world for twelve consecutive years, selling to 123 countries and regions.

Jingjin’s trademark has been awarded the prestigious designation of “China Famous Brand” by the State Administration for Industry and Commerce of the People’s Republic of China. The company’s trademark is also protected through the Madrid International Trademark Registration. Moreover, Jingjin’s chairman, Water Jiang, has been recognized as a National Model Worker.

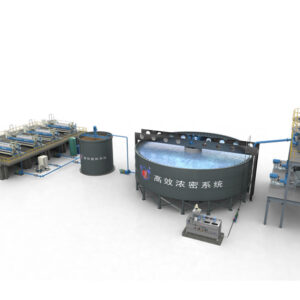

As A Leading Global Service Provider, JINGJIN

JINGJIN strives to achieve the Chinese dream of becoming a global leader in environmental protection services. Its mission is to “protect the environment and enhance the beauty of China,” and its eco-friendly strategy of “transforming wastewater into pure water and sludge into resources” offers a comprehensive solution for environmental protection while promoting economic development. The ultimate objective is to leave a cleaner environment with pure water and blue skies as a legacy for future generations.

JINGJIN Introduced A Complete Set Of German Equipment

JINGJIN is dedicated to building a career centered on energy conservation and environmental protection. The company offers cost-effective products and high-quality professional services to consumers.

- In order to achieve better filtering requirements, Jingjin introduced a complete set of German filter cloth production line and tehnology.

- By virtue of jingjin’s 27 years of filtering experiende, the heavy German rapier looms weave the thinnest silk threads into filter cloth of high density and different hole patterns by using 0.3-3.5 tons beating-up force after each weft across warp.

- Under same area the filtration holes of JIngjin filter cloth are 50% more than other iflter cloth, which improve the filtration speed greatly.

- The filter cloth was woven under constant temperature and humidity ,which eliminate the fabric burrs caused by static electricity.

The ability of the monofilament filter cloth to enable automatic detachment of the filter cakes is a critical aspect that resolves a long-standing issue.

Quick Details

Supply Ability

- Supply Ability:10000 Set/Sets per Year

Packaging & Delivery

- Packaging Details:Seaworthy packing

- Port: Tianjin

- Lead Time: 15days from prepayment