Filter Press

Showing 10–18 of 54 results

-

vacuum filter press

-

Intelligent Type II Quick Opening Filter Press

-

Automatic Locking Filter Press

-

Energy Saving And Efficient Water Washing Vibrating Filter Press

-

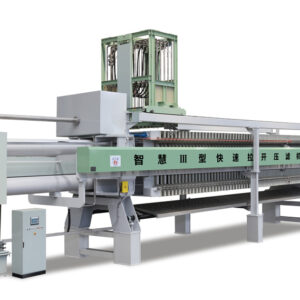

Intelligent Type III Quick Opening Filter Press

-

External Washing And External Discharge Vibrating Pressure Filter

-

China Automated Vacuum Filter Press Manufacturer

-

Intelligent Type I Quick Opening Filter Press

-

Jingjin High Efficiency Energy Saving Filter Press