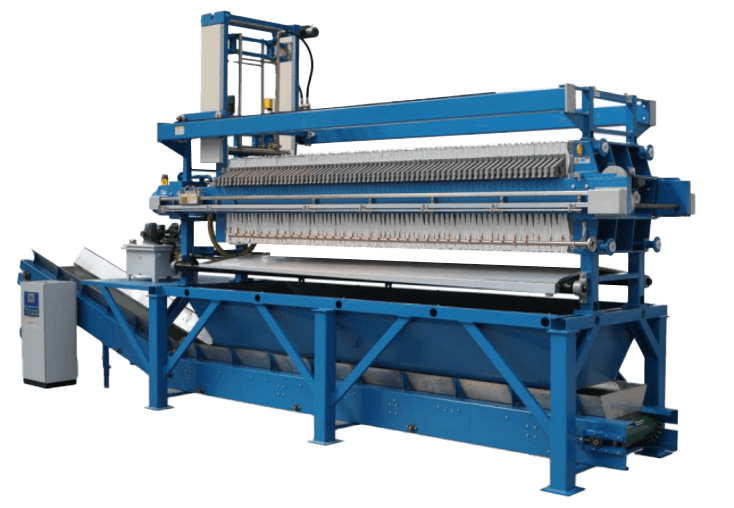

Jingjin Filter press is a powerful tool used in the filtration industry to separate solids and liquids. It can applicate in a wide range of applications, including wastewater treatment, chemical processing, mining, and food production. In this article, we’ll provide a comprehensive guide to what filter press is used for and how it works.

What is Filter Press Used for?

Filter press is popular for a variety of applications, including:

- Wastewater Treatment: A filter press plays an important role in wastewater treatment plants to separate solids from liquids.

- Chemical Processing: It can applicate in the chemical processing industry to separate solids from liquids in chemical reactions.

- Mining: A filter press is popular in the mining industry to separate minerals from water.

- Food Production: The equipment plays an important role in the food production industry to separate solids from liquids in food processing.

How Does Filter Press Work?

Filter press works by separating solids from liquids through the use of pressure. The process involves the following steps:

- Charging: The slurry, which is a mixture of solids and liquids, will pump into the filter press.

- Filtration: The equipment forces through the filter cloth, and the solids can trap on the cloth, while the filtrate, which is the liquid, passes through.

- Washing: The filter cake, which is the solids trapped on the cloth, washing to remove any remaining liquid.

- Drying: The equipment then dring to remove any remaining moisture.

- Discharging: The dry filter cake is removed from the filter press, and the process is repeated.

Types

There are several types of filter press, including:

- Plate and Frame Filter Press: This type of filter press uses a series of plates and frames to separate solids from liquids.

- Recessed Chamber Filter Press: This type of filter press uses a series of chambers to separate solids from liquids.

- Membrane Filter Press: This type of filter press uses a membrane to squeeze the filter cake and remove any remaining liquid.

Benefits of Using a Filter Press

Some of the benefits of using a filter press include:

- Efficiency: Filter press is a highly efficient filtration solution that can separate solids from liquids quickly and effectively.

- Cost-Effectiveness: Filter press is a cost-effective filtration solution that can reduce labor and material costs compared to other filtration methods.

- Environmental Friendliness: Filter press is an environmentally friendly filtration solution that can reduce the amount of waste produced and the need for additional treatment.

- Consistent Results: Filter press provides consistent and reliable filtration results, ensuring that the filtrate meets the desired specifications.

- Versatility: Filter press is a versatile filtration solution. That can applicate in a wide range of applications, including wastewater treatment, chemical processing, mining, and food production.

- Minimal Maintenance: Filter press requires minimal maintenance, making it a low-maintenance filtration solution that can save time and money.

JingJin filter manufacturer’s strength

JingJin Filter Press is a high-quality filter press manufacturer that offers a wide range of filtration products and solutions. With over 30 years of experience in the industry, JingJin has established itself as a trusted and reliable brand. Their products are made with high-quality materials and advanced technology, ensuring that they are efficient, effective, and long-lasting.

JingJin offers customization options to ensure that their filter presses meet their customers’ exact specifications. And they commit to providing exceptional service from start to finish. Choosing JingJin Filter Press as your filtration solutions provider is a smart choice for anyone looking for high-quality, reliable, and efficient filtration solutions.

Conclusion

Filter press is a powerful tool applicate in the filtration industry to separate solids from liquids. It is popular in a wide range of applications, including wastewater treatment, chemical processing, mining, and food production. The filter press works by using pressure to force the slurry through a filter cloth, separating the solids from the liquids. There are several types of filter press, including plate and frame filter press, recessed chamber filter press, and membrane filter press. By understanding what filter press can applicate for and how it works, you can make an informed decision about whether it is the right filtration solution for your needs.