What is a press cloth

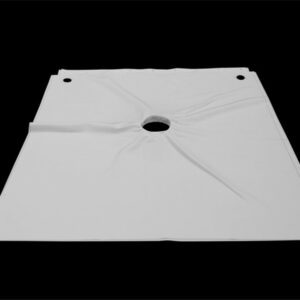

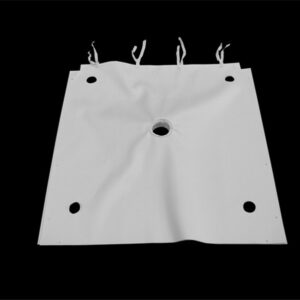

The filter cloth is a medium in which the real filtration takes place. The filter cloth is mounted on the depleted surface of the filter plate. As the slurry nourishes within the filter plate cavity, the slurry is filtered through the filter cloth.

Jingjin is a worldwide specialist in filter cloth, which is the key to enhanced filter press operation. We investigate each customer’s process and application very carefully to design filter cloths to suit each customer’s demanding requirements. From natural materials to synthetic and felt materials, Jingjin offers a wide range of quality premium filter cloth materials to meet your filtration needs.

We know that a guaranteed quick response turnaround is your best satisfaction. We work with trusted suppliers close to our assembly area to ensure we have the fabric you need for your specific application.

Features

- Jingjin is the first and last source of filter cloth for your filter press.

- The right choice of material can affect performance. Jingjin has one of the widest ranges of available materials. We will help you select the ideal material for your application.

- The weave of the filter cloth also depends on your specific application. For example, if your application is gold mining, we have filter cloths specifically designed to withstand extreme pressure and can capture particles as small as 0.05 microns. If your application is metal surface treatment, or other heavy industrial applications that require cleaning and treatment of industrial wastewater, we can provide filter cloths to meet your specific needs. Find out how to select the right filter cloth for your dewatering process.

- Our state-of-the-art laboratory staff can assist you in determining the specifications of your filter cloth. As there are different types of fabric tissues and materials, we want to ensure that the correct fabric is specified for your application. Your filter cloth specification will depend on the size of the filter press and the dewatering application it is used for. For example, a battery recycling plant will use different sizes of filter cloth and filter presses, while a municipal power plant application is separating their slurry from sulphur dioxide.

Technical Data of the Filter Cloths

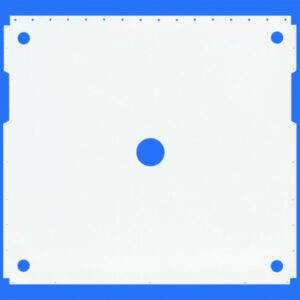

| Format | Standard Sizes (in mm): 400, 470, 500, 630, 800, 915, 1000, 1067, 1200, 1300, 1450, 1470, 1500, 1500 x 2000 and 2000 x 2000 mm. These formats are available in open and closed versions. Larger and differently sized formats on request. |

| Sludge Inlet | Filter Cloths can be made of the following materials for specific applications:Polypropylene (PP) (heat-stabilized and if necessary calendared)Polyamide (Nylon-6 &6.6), (heat-stabilized)Polyester (PET), (Heat set calendared)PBT (Heat set calendared)Cotton, Poly CottonOther materials on request |

| Materials | Depending on the version, standard products are suitable for a maximum filtration pressure of 8 bar or 16 bar. |

| Temperature | The maximum permissible filtration temperature depends, among other things, on the filtration pressure, the chemical composition of the slurry to be filtered, the cycle time and the choice of material. |

| Pressure | Standard inlets: central inlet, decentralized inlet, corner inlet |

| Weaves | SPUN yarnMultifilament yarnMonofilament yarnYarn blends (Multi x Spun& Mono x Multi)Plain weaveBroken twill weaveTwill weaveSatin weave |

| Versions | Filter cloths can be made for Non-Gasketed (NG) or Caulked, Gasketed Recessed (CGR) chamber plates. |

Supply Ability

Supply Ability:500 Set/Sets per Day

Packaging & Delivery

Packaging Details:seaworthy packing

Port:Tianjin

Lead Time:5days