What Is Membrane Filter Press? From wastewater treatment to manufacturing, membrane filter presses offer enhanced filtration efficiency, versatility, and improved productivity. Unleash the power of membrane filter presses and revolutionize your filtration operations.

What is a Membrane Filter Press

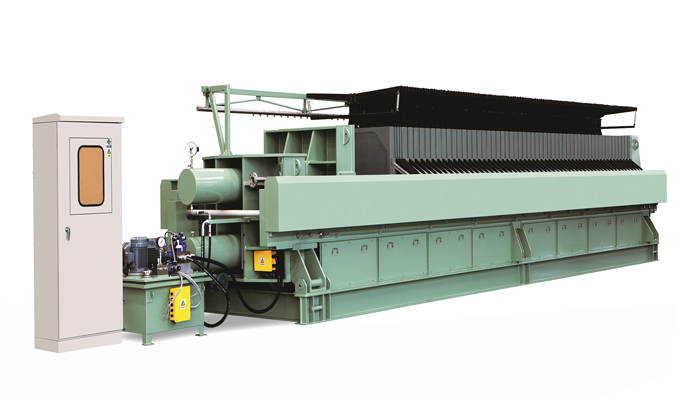

A membrane filter press is an advanced filtration system used to separate solids from liquids in various industrial processes. It consists of a series of filter plates with flexible membranes interlaid between them.

These membranes apply additional pressure to the filter cake, enhancing the dewatering process. By combining mechanical compression and membrane squeezing, membrane filter presses achieve higher filtration efficiency compared to traditional filter presses.

Working Principle of Membrane Filter Press

The operation of a membrane filter press involves a series of sequential steps. Initially, the slurry or suspension is pumped into the press, filling the chambers between the filter plates. As the filtration process commences, solids accumulate on the filter cloths, forming a filter cake.

Subsequently, high-pressure hydraulic systems compress the membranes, exerting additional pressure on the cake. This pressure facilitates the separation of the remaining liquid, resulting in a drier filter cake. The separated filtrate can then be collected for further processing or disposal.

Applications of Membrane Filter Press

Membrane filter presses find extensive applications across numerous industries. In wastewater treatment plants, they efficiently separate solids from liquids, aiding in the removal of contaminants.

The pharmaceutical industry utilizes membrane filter presses for the purification of active pharmaceutical ingredients and the recovery of valuable byproducts. Other applications include mining operations, chemical manufacturing, food processing, and ceramics production.

Enhanced Filtration Efficiency

One significant advantage of membrane filter presses is their superior filtration efficiency. Through the combination of mechanical compression and membrane squeezing.

These presses ensure thorough dewatering, resulting in a reduced moisture content in the filter cake. This, in turn, leads to higher productivity and shorter filtration cycles, ultimately enhancing process efficiency.

Versatility in Industrial Applications

Membrane filter presses offer versatility, making them indispensable across various industries. In mining operations, they facilitate the separation of valuable minerals from slurry.

The chemical industry relies on membrane filter presses for efficient separation and purification of chemical compounds. Additionally, they play a crucial role in the food and beverage industry, ensuring the removal of impurities and the production of high-quality products.

Conclusion:

Membrane filter presses have revolutionized industrial filtration, offering enhanced efficiency and improved productivity. With their ability to achieve thorough dewatering, versatility in applications, and superior filtration efficiency, these devices have become essential in diverse industries.

Embrace the power of membrane filter presses and unlock the potential for increased efficiency and productivity in your filtration processes.