What is a filter press?

The filter press uses a special filter medium to apply a certain pressure to the object to make the liquid dialysis out of a mechanical device. It is a commonly used solid-liquid separation device. Basically, each filter press is designed based on the volume and type of slurry that needs to be dewatered.

Jingjin fiterpress is a trusted expert in liquid/solid separation and offers a wide range of filter press types and capacities to suit specific application needs for trouble-free, economical dewatering. These include configurations such as sidebar automatic, manual overhead, automatic dual overhead beam, stainless steel clad, explosion-proof filter presses, vacuum filter presses, and hand filter presses.

How does a Filter Press Work?

The hydraulic pressure mechanism of the filter press consists of a hydraulic station, an oil cylinder, a piston, a piston rod, and a Hafland card hydraulic station that connects to the piston rod and the pressure plate.The structure consists of a motor, an oil pump, and an overflow valve (pressure adjustment). Directional valve, pressure gauge, oil circuit, oil tank.

Filtration method:open flow filtration and undercurrent filtration.

- For open flow filtration, a water nozzle is installed on the outlet hole under each filter plate, and the filtrate flows out from the water nozzle intuitively.

- Undercurrent filtration involves arranging a liquid outlet channel hole beneath each filter plate. The liquid outlet holes of multiple filter plates are interconnected to create a continuous liquid outlet channel. The liquid is then discharged through a pipe connected to the liquid outlet hole located under the thrust plate.

Washing method: There are sometimes one-way washing and two-way washing, undercurrent one-way washing and two-way washing.

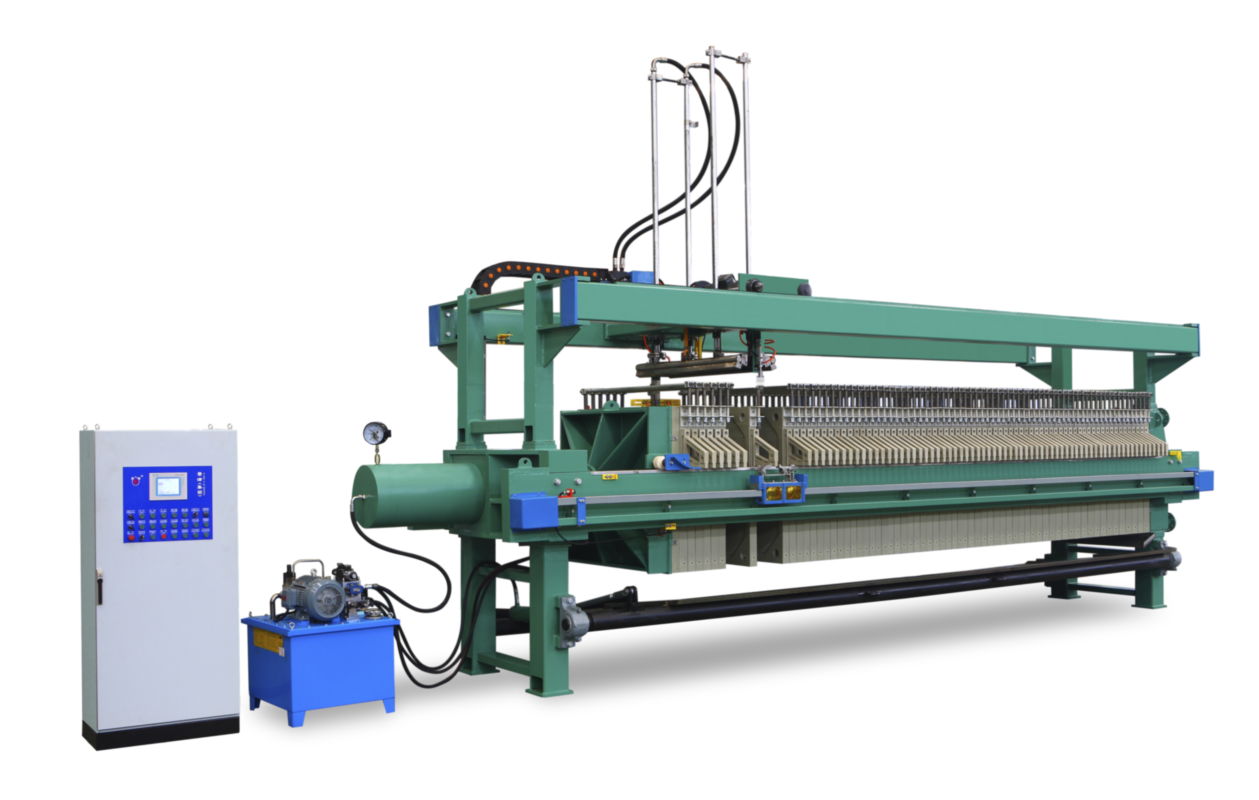

View Our Filter Press Machines

Customizing A Filter Press for Your Application Needs

Industry, application and operational considerations will guide specific details such as overall design, filtration capacity, number of chambers, filter plate size, materials of construction, and other features/systems such as automatic plate shifters, cloth cleaning systems, drip pans, cake guards and safety light curtains. The design of the filter press depends on many factors such as the filtration cycle time, desired cake dryness, filter cloth life, the need for manual or automatic plate movers, and many other factors.

The structure of the filter press consists of three parts:

1. frame

- Thrust plate

- Pressure plate

- Girder

2. Hold-down mechanism

- Manual compression

- mechanical compression

- hydraulic compression

3. Filter mechanism

The filter mechanism comprises a filter plate, a filter frame, a filter cloth, and a squeeze diaphragm. The filter plate has filter cloth covering both sides. When a squeeze diaphragm is required, a filter plate set consists of a diaphragm plate and a side plate. Rubber diaphragms cover both sides of the base plate of the diaphragm plate, and filter cloth covers the outside of the diaphragm.

The side plates are ordinary filter plates. The material enters the filter chambers from the material holes on the thrust plate. The filter chambers trap solid particles due to their particle size exceeding the pore size of the filter medium (filter cloth). Meanwhile, the filtrate exits through the outlet holes located under the filter plate. When the filter cake requires further drying, squeezing can be performed using a diaphragm or by introducing compressed air or steam through the washing port. This airflow helps flush water from the filter cake, reducing its moisture content.

Basically, the filter press design is based on the dewatering volume and type of slurry. JingJin is an expert in liquid and solid separation and offers a wide range of filter press types and capacities to suit specific application needs for trouble-free, economical dewatering.

Dehydration application

Filter presses are versatile pieces of equipment used in a variety of applications to separate solids from liquids. Some common applications of filter presses include:

- Mining and minerals:

- Filter presses find application in the dewatering of slurry produced during mining and minerals processing. The presses can extract valuable metals and minerals from the slurry, making it easier and more cost-effective to transport and dispose of the remaining material.

- Chemical processing: In chemical processing applications, filter presses are employed to separate solids from liquids. They serve purposes such as filtering catalysts, eliminating impurities from chemicals, and clarifying liquids.

- Food and beverage:Filter presses play a crucial role in filtering and clarifying various liquids, including wine, beer, and fruit juices. They are also utilized to remove solids and impurities from cooking oils and other food products.

- Pharmaceuticals: filter and purify pharmaceutical products. remove impurities and ensure that the final product is free of contaminants.

- Municipal wastewater treatment: Filter presses are used in municipal wastewater treatment plants to dewater sludge generated during the treatment process. This allows the sludge to be transported and disposed of more easily and effectively.

- Industrial wastewater treatment: in a variety of industrial wastewater treatment applications to separate solids from liquids. filter wastewater from manufacturing processes, remove heavy metals and other contaminants from industrial wastewater, and more.