filter press plates definition

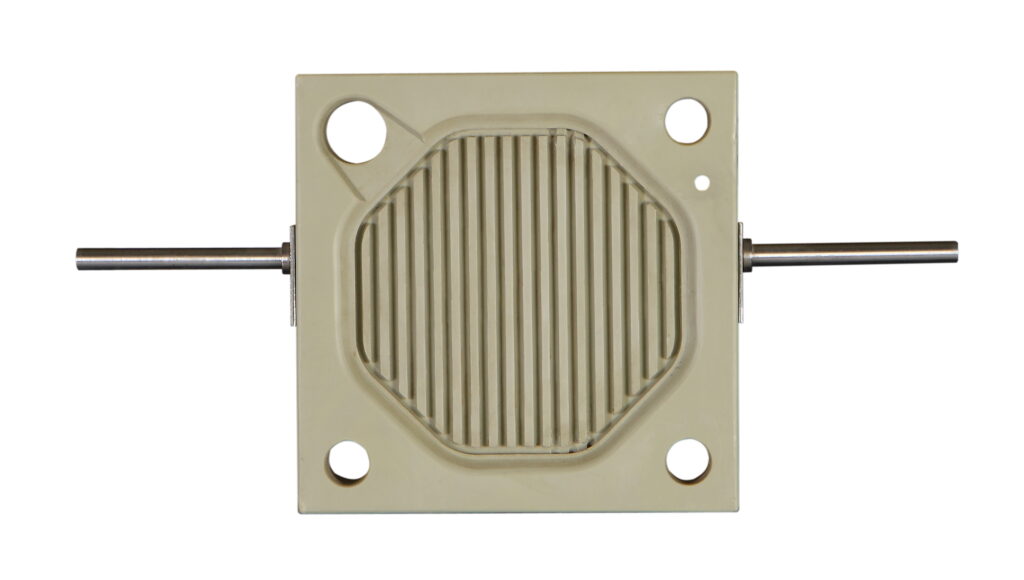

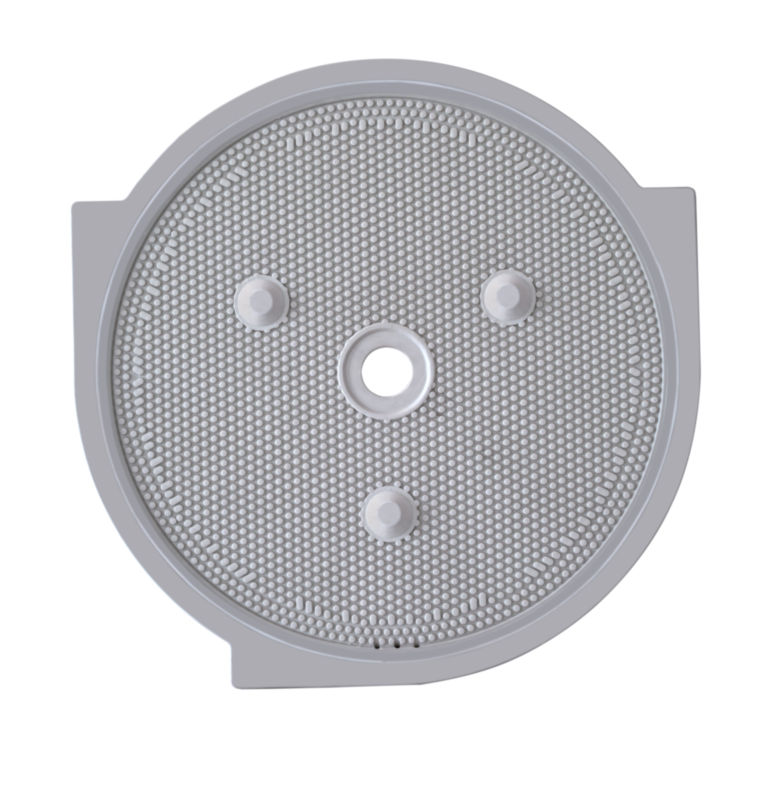

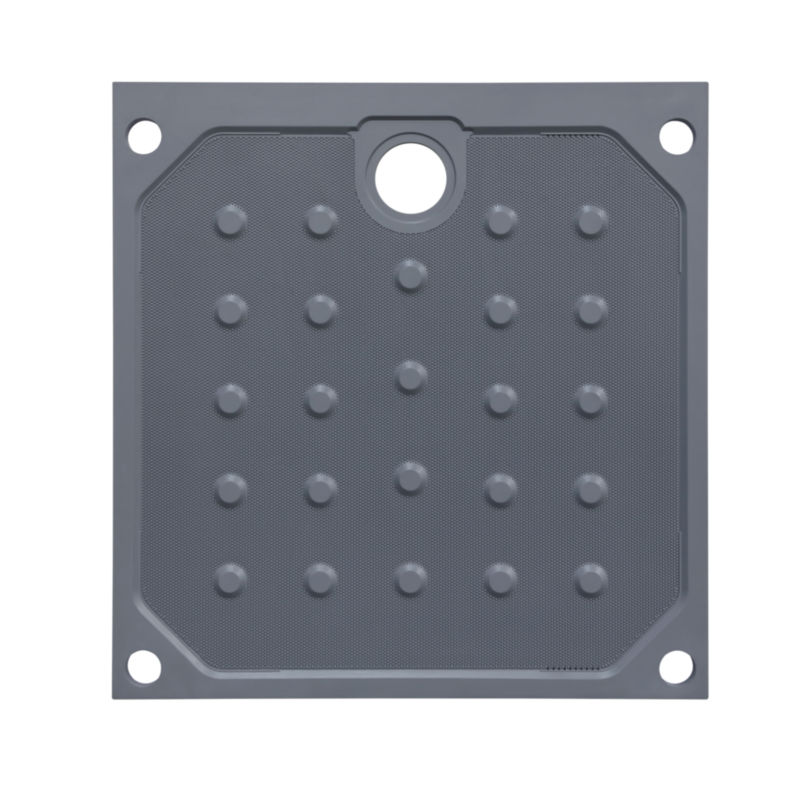

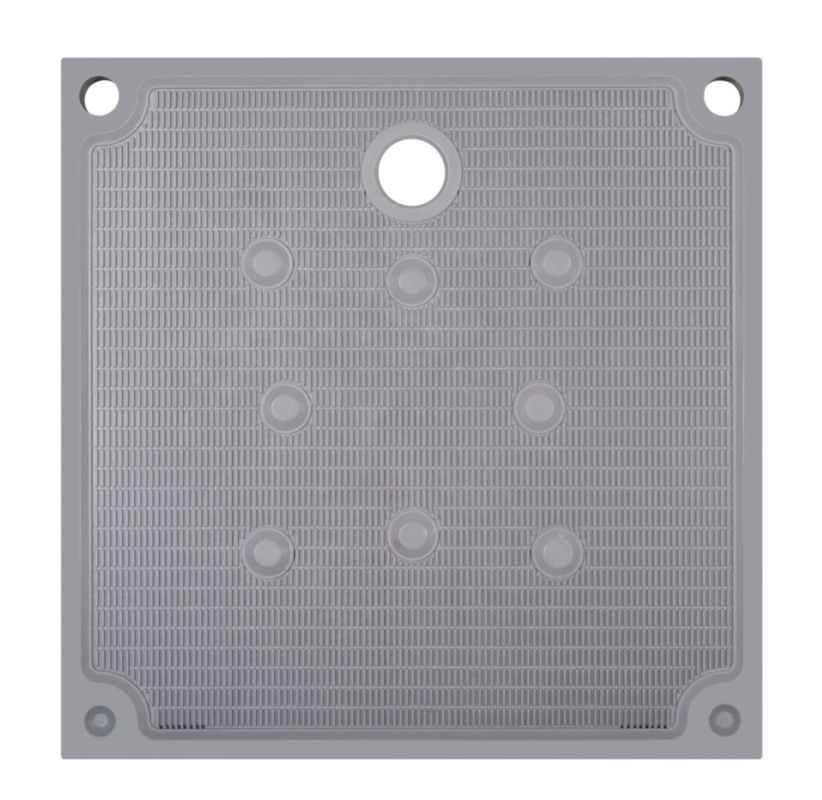

A filter press plate is a component of a filter press machine used in solid-liquid separation processes. Filter plates are typically made of a variety of materials such as polypropylene, stainless steel, cast iron, or aluminum. They come in different shapes and sizes depending on the application and filtration requirements.

Filter press plates are designed to provide a stable and flat surface for the filter cloth, which is used to capture solids during the filtration process. They are arranged in a series, with each plate separated by a frame or spacer. The feed slurry is pumped into the press, and the solids are captured by the filter cloth while the filtrate passes through the plates and is collected in a discharge manifold.

The design of filter plates can have a significant impact on the efficiency and performance of the filter press. Factors such as plate size, plate shape, and the number of plates used can affect the filtration rate, cake thickness, and the quality of the filtrate. The material used to make the plates also determines their durability and resistance to chemical and thermal degradation.

Materials of filter press plates

Filter press plates can be made of various materials depending on the application and filtration requirements. Some of the commonly used materials for filter plates are:

- Polypropylene: Polypropylene is a thermoplastic polymer that is lightweight, durable, and resistant to chemicals and high temperatures. Polypropylene plates are widely used in the food and beverage industry, as well as in pharmaceutical and chemical processing applications.

- Stainless Steel: Stainless steel is a durable and corrosion-resistant metal that is used in filter plates for applications that require high temperatures or acidic environments. Stainless steel plates are commonly used in the oil and gas industry, as well as in chemical and food processing applications.

- Cast Iron: Cast iron is a heavy and durable metal that is used in filter plates for applications that require high pressure and temperature. Cast iron plates are commonly used in mining and mineral processing applications.

- Aluminum: Aluminum is a lightweight and corrosion-resistant metal that is used in filter press plates for applications that require high strength and durability. Aluminum plates are commonly used in the aerospace industry, as well as in food and beverage processing applications.

The choice of material for filter press plates depends on various factors such as the type of slurry being filtered, the temperature and pressure conditions, and the required chemical resistance.