Understanding the ins and outs of plate and frame filter press operation in this comprehensive guide. From the basic principles to practical tips, this article provides a detailed overview of how this filtration technique works.

Principles of Plate and Frame Filter Press Operation

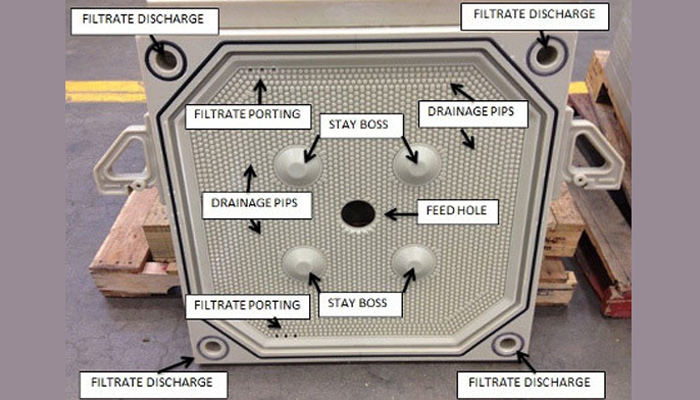

Plate and frame filter press operation relies on a simple yet effective mechanism. The equipment consists of a series of filter plates and frames, which are alternately stacked.

A filter cloth is placed between each plate and frame, creating chambers for the filtration process. When the slurry is pumped into the press, the liquid component passes through the filter cloth, while the solids are retained, forming a filter cake.

Step-by-Step Guide to Plate and Frame Filter Press Operation

- Preparation: Before starting the operation, ensure that the filter plates and frames are clean and in good condition. Also, check the filter cloth for any tears or damages.

- Loading: Place a filter cloth on each side of the filter plate and secure them with the frame. Stack the plates and frames together, ensuring proper alignment and tightness.

- Filtering: Connect the slurry feed pump to the press and start pumping the slurry into the chambers. As the slurry fills the chambers, the liquid component passes through the filter cloth, while the solids form a filter cake.

- Drying: Once the filtration is complete, stop the slurry feed and allow the filter cake to dry. This can be done by applying air pressure or by simply exposing the filter cake to air.

- Discharging: After the filter cake is dry, the plates and frames can be separated, and the filter cake can be discharged for further processing or disposal.

Tips for Optimizing

- Proper Filter Cloth Selection: Choose a filter cloth material that is compatible with your slurry composition and desired filtration efficiency. Factors such as particle size, pH, and temperature should be considered when selecting the filter cloth.

- Optimal Pumping Rate: Adjust the slurry feed rate to ensure a steady and uniform flow. This helps in achieving consistent filtration results and prevents excessive cake buildup.

- Regular Maintenance: Perform routine inspections and cleaning of the filter plates, frames, and cloth to prevent clogging and ensure optimal performance. Replace worn-out or damaged components promptly.

Example Application of Plate and Frame Filter Press Operation

One example of plate and frame filter press operation is in the pharmaceutical industry. During the production of medicines, this filtration technique is utilized to separate solids from liquid solutions, ensuring product purity and quality.

By employing the plate and frame filter press, pharmaceutical manufacturers can achieve efficient removal of impurities, such as active ingredients or contaminants, leading to safer medications for consumers.

Conclusion

Plate and frame filter press operation is a reliable and widely used method for efficient filtration. To understand the principles, follow the step-by-step guide. And implementing optimization tips, operators can maximize the performance of this filtration equipment.

Whether in pharmaceuticals, chemicals, or other industries, the plate and frame filter press offers an effective solution for separating solids and liquids, contributing to improved product quality and process efficiency.