When it comes to industrial filtration, selecting the right type of filter press is crucial for achieving optimal results. Different applications demand specific filtration requirements, and understanding the various types of filter presses available is essential. Now we will explore the different types of filter presses, and their unique features.

Types of filter presses

1. Plate and Frame Filter Press

The plate and frame filter press is one of the most common types used in numerous industries. It consists of a series of plates and frames arranged alternately. The plates have filter media, such as filter cloth or filter paper, to capture the solids, while the frames provide support. This type of filter press offers versatility, ease of operation, and efficient solid-liquid separation. It is suitable for applications with high solids content, such as mining, pharmaceuticals, and chemical processing.

Example: Plate and Frame Filter Press in the Beverage Industry

For instance, in winemaking, these presses effectively remove sediments, particles, and impurities, resulting in clearer and more refined wines. The plate and frame design allows for easy cleaning and maintenance, ensuring the production of high-quality beverages.

2. Recessed Chamber Filter Press

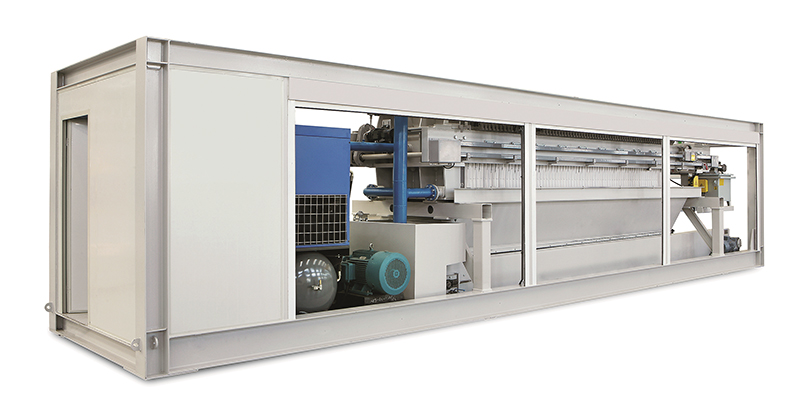

The recessed chamber filter press features recessed plates that create chambers between them when compressed. The chambers are filled with the slurry to be filtered, and the filtrate passes through the filter media while the solids are retained. This type of filter press is popular for its high-capacity filtration, efficient cake formation, and excellent cake-washing capability. It plays an important role in wastewater treatment, mining, and chemical industries.

Example: Recessed Chamber Filter Press in Wastewater Treatment

In wastewater treatment plants, recessed chamber filter presses play a vital role in dewatering sludge and separating solids from liquids. The recessed design allows for effective cake formation, resulting in a higher solids content in the filter cake. This, in turn, reduces disposal costs and facilitates proper waste management.

3. Membrane Filter Press

The membrane filter press combines the features of the plate and frame filter press with an additional elastomeric membrane. By exerting pressure on the filter cake, the membranes enhance dewatering and reduce moisture content. Membrane filter presses are commonly used in industries requiring high-pressure filtration, such as mining, chemical manufacturing, and wastewater treatment.

Example: Membrane Filter Press in Mining Operations

In mining operations, membrane filter presses are instrumental in extracting valuable minerals from slurries. By applying high-pressure squeezing, these presses efficiently separate the solids from the liquid phase, resulting in a drier filter cake and increased mineral recovery. The membrane technology improves process efficiency and reduces environmental impact.

Conclusion

Choosing the right type of filter press is essential for optimizing your industrial filtration processes. The plate and frame filter press, recessed chamber filter press, and membrane filter press offer unique features and advantages for different applications. By understanding their characteristics and applications, you can select the most suitable filter press to achieve efficient solid-liquid separation, improved productivity, and cost-effective solutions. Evaluate your filtration needs, consult with filtration experts if necessary, and invest in the right filter press for your specific requirements.

Find the Perfect Filter Press for Your Filtration Processes

If you’re searching for the ideal filter press for your industrial filtration needs, our experts are here to assist you. Contact us today to explore the various types of filter presses available and find the perfect solution to enhance your filtration efficiency.