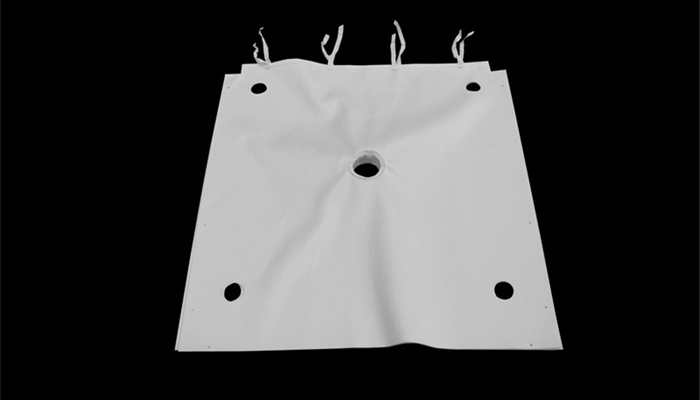

Filter press cloth is an essential component in any filtration system, and it plays a crucial role in removing impurities. In this article, we will discuss troubleshooting techniques for filter press cloth and how to identify and address common problems.

How to Choose the Proper Filter Press Cloth?

Are you experiencing issues with your filter press cloth? Are you unsure of how to choose the proper filter press cloth for your specific needs? Look no further! In this article, we will discuss the common issues encountered with clothes, how to troubleshoot them, and most importantly, how to choose the right clothes for your application.

Troubleshooting Filter Press Cloth Issues

- Clogging: One of the most common issues encountered with cloth is clogging. This can be caused by a variety of factors, including improper cleaning, excessive use, or damaged clothes. To troubleshoot clogging, check the cloth for any visible damage or debris. If the cloth is damaged, replace it with a new one. If the issue persists, try cleaning the cloth with a mild detergent and water.

- Leaking: Another common issue with press cloth is leaking. This can be caused by improper installation, damaged cloth, or worn-out gaskets. To troubleshoot leaking, check the gaskets for any signs of wear or damage. If the gaskets are damaged, replace them with new ones. If the issue persists, check the cloth for any holes or damage and replace it if necessary.

- Low Flow Rate: A low flow rate can be caused by a variety of factors, including clogging, worn-out cloth, or improper installation. To troubleshoot a low flow rate, check the cloth for any blockages or damage. If the cloth is damaged, replace it with a new one. If the issue persists, check the installation and make sure it is proper.

Choosing the Proper Filter Press Cloth

Choosing the proper clothes can be a daunting task, but it doesn’t have to be. Here are some tips to help you choose the right clothes for your application:

- Consider the Type of Fluid: The type of fluid being filtered will play a significant role in choosing the proper filter press cloth. Different fluids require different types of cloth, so it’s essential to consider this factor when making your selection.

- Consider the Particle Size: The particle size of the fluid being filtered will also play a role in choosing the proper cloth. A larger particle size will require a coarser cloth, while a smaller particle size will require a finer cloth.

- Consider the Operating Conditions: The operating conditions of the filter press, such as temperature, pressure, and flow rate, will also affect the choice of cloth. It’s essential to consider these factors when selecting the cloth to ensure it can withstand the conditions.

- Consider the Cost: The cost of the cloth is also an essential factor to consider. While it’s important to choose a high-quality cloth, it’s also important to consider the cost and make sure it fits within your budget.

Conclusion

In conclusion, filter press cloth is a crucial component in various industrial applications, and choosing the proper cloth can be a challenging task. By understanding the common issues encountered with the cloth and following the tips outlined above, you can choose the right cloth for your specific needs. Remember to consider the type of fluid, particle size, operating conditions, and cost when making your selection. With the right cloth, you can ensure your filter press operates efficiently and effectively.