Wastewater treatment plants face the complex challenge of cleaning contaminated water for release back into the environment. Several steps are required to remove solids, pollutants, and impurities from wastewater streams. [Filter presses] have become a vital technology for dewatering sludge and separating solids from liquids during filter press in wastewater treatment.

How Filter Presses Work

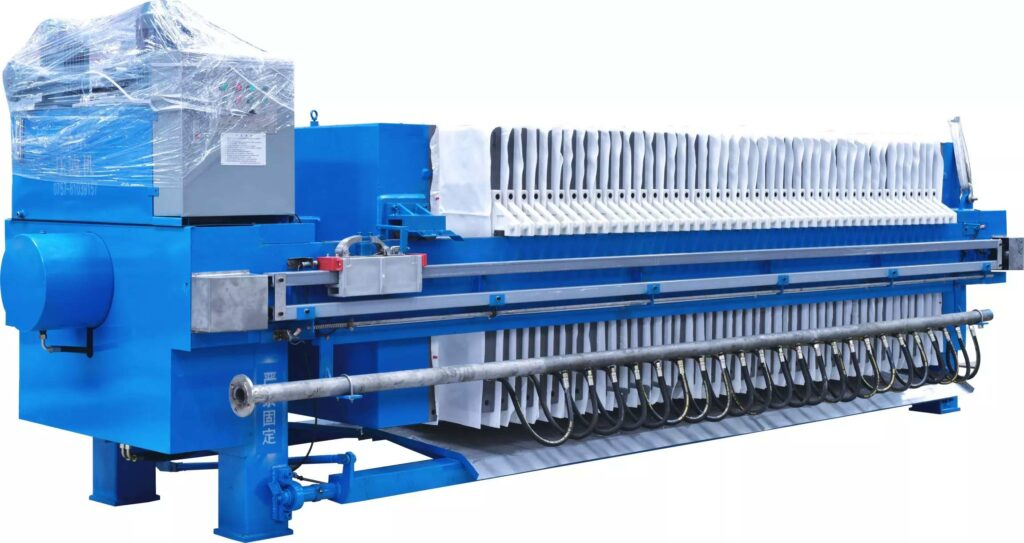

Filter presses are used as a fixed volume, batch operation process. First, a pump feeds the wastewater slurry into the filter press unit. The slurry enters filter cloth chambers and the filtrate exits through the cloth, while solids are trapped and compacted into cakes. Once a batch is complete, the filter plates open and the solid filter cakes are removed.

There are two main components that make up a filter press:

- Filter Plates – The filter chambers are constructed of rectangular plates lined with filter cloths. The plates are sealed on all sides and arranged side-by-side in a frame.

- Filtrate Head – The head applies pressure to the filter chambers to enhance the filtration process. It collects and discharges the filtrate.

Types of Filter Presses

There are several different filter press designs and models available for handling various waste slurries.

- Plate and Frame – This is the most common type. It uses separate framed plates lined with cloth, separated by gaskets.

- Chamber – Chamber filter presses contain pre-assembled plates in a filter block design. This allows faster maintenance.

- Membrane – Membrane filter presses utilize pre-coated filter cloths. Flow passes through the cloth, not between chambers.

- Belt – Belt filter presses are continuous processes rather than batch. Two belts compress the sludge and move it between heavy rollers.

Applications In Wastewater Treatment

Filter presses are utilized for several important functions in the wastewater treatment process flow:

- Sludge Dewatering – Thickening and dewatering sludge is a crucial treatment step. Filter presses remove excess water from the sludge before disposal.

- Slurry Separation – Filters separate undesirable solids like fats, oils, and grease from wastewater streams entering the plant.

- Algae Removal – Filters remove algae from clarified water before disinfection and discharge.

- Chemical Treatment – Adding coagulants/flocculants causes particles to clump together. Filters remove these larger particles.

- Leachate Processing – Landfill leachate contains contaminants requiring filter pressing for solid-liquid separation before further treatment.

Advantages of Filter Presses

There are several important benefits provided by filter press systems:

- High Solids Capture – Filter presses reliably remove up to 75% of solids, and even higher with coagulant aids. This reduces sludge volume.

- Fully Automated – Modern filter press operations can be fully automated using programmable PLCs. Some units even include automatic cloth washing systems.

- Low Operating Costs – Filter presses have relatively low energy requirements and maintenance costs compared to other separation methods.

- Dry Cake – Filter presses produce dry sludge cakes up to 40% solids or more. This minimizes rehandling of wet sludge.

- Enclosed System – The closed filter press chamber contains odors and prevents exposure to operators.

- Flexible Capacity – Capacity can be increased by adding more filter plates to the frame.

By utilizing filter pressing, wastewater plants can minimize waste volumes, meet regulatory requirements, and reduce operating costs for solids processing. With capacities up to 100s of cubic meters per hour, today’s filter presses are a smart and efficient solution for modern wastewater treatment.