Wastewater treatment is a very important task in the process of keeping the environment clean and ensuring that regulatory standards are strictly followed. One of the most effective means of purifying wastewater in treatment plants is by using the filter press, which separates solids from liquids efficiently. The electrical energy required to operate a newer version of a filter press is one of the 12 actions to save the planet. Installation of a modern filter press system is thus very beneficial to environment, as it not only reduces the trash but also makes water recoverable. This piece discusses the significance of utilizing the most recent filtration technology and gives examples of wastewater treatment stations that can benefit from it.

What is a Filter Press and How Does it Work?

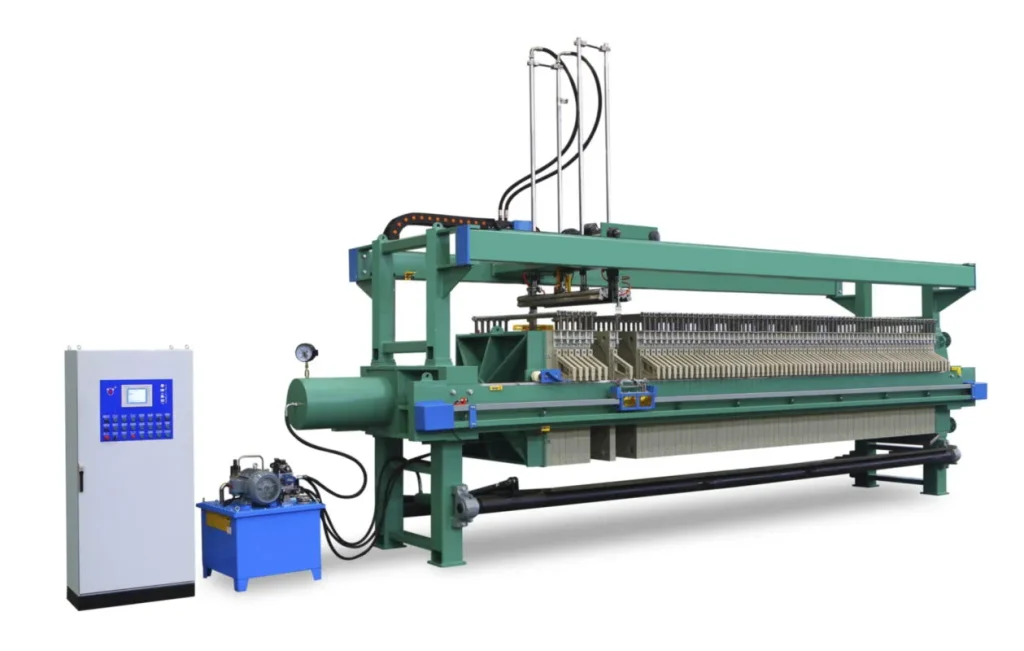

A filter press in wastewater treatment is a unique tool designed to eliminate undesired matters from industrial and municipal wastewater. The method requires the application of external pressure to a slurry to force water through a filter membrane which captures the solid contaminants. The solid that was trapped, also known as filter cake, can after that be either thrown away or recycled depending on its content.

Key Environmental Benefits of a New Wastewater Filter Press

1. Reduced Waste and Sludge Volume

One of the best things about the new wastewater filter press is its capability to make a notable reduction in sludge volume. A filter press is energy-efficient which helps to save on the cost of energy consumption by improving the process of sludge dewatering. This is therefore, only one of the benefits of the system that not only helps to reduce wastes that go to the landfill but also further extends to the reduction of waste transportation costs and emissions. This measure in particular is one of the essential steps in sustainable solid waste management.

2. Enhanced Water Recovery and Reuse

A water filter press of the current time can be a significant asset in the reuse of water resources and closing the water cycle in the global community. The recoverable water allows an industrialized society to reduce pressure on their water resources saving them for other purposes such as drinking, agriculture, cooling for thermal power plants, etc. Moreover, returning treated water to nature without disturbing the ecological balance is among the most sustainable practices in water sector.

3. Lower Energy Consumption

Modern applications are made in such a way that these require less energy when compared to the original ones which have been instrumental in reducing the energy consumption of such industries. This is achieved through energy-efficient components and remote, e.g. automatic instruments, which can be programmed based on the needs for filtration. Greenhouse gases that cause global warming are also minimized through this.

4. Minimized Chemical Usage

Temporary membraning in a wastewater treatment plant calls for chemical additions which contribute largely to the formation of new disposed chemicals that are harmful to the environment. In comparison, the design of the new filter press allows a very minimum amount of chemicals which results in less cost and less exposure to the environment. Chemical pollution is kept to minimum levels hence the aquatic life is preserved, and we also prevent the surroundings from being contaminated by the chemicals.

5. Compliance with Environmental Regulations

EPA legislation that succeeded in controlling the emission standards in favor of wastewater treatment plants was the Clean Water Act. Solution to this rat is to incorporate technologies that have been tested and shown to be able to generate the clarified water thus hold the advantage of the developed countries that are in constant improvement of product density, milk processing, sewage treatment, etc., over the developing countries whose advancement is still limited to fathering agriculture, fishing, and sleeping after lunch. This is a biohazard and disease transmission! Quality control and public safety are directly affected. As usual, danger topics are not being made clear, and this is the worst and furthest along case! With a filter press, manufacturers consequently always manage to switch to the other extreme if the gasket is installed wrong, insufficient or missing. Basic proper handling only requires that the support cylinders are not only kept clean and well maintained but also that the conveyor is not operated at any time with the cylinder or the belts in bad shape. Production material loss is little, which vastly saves the consumer order. The assembly of the TOX®, Inc. is simple and basically a two people job.

Choosing the Right Filter Press for Your Facility

Selecting the best wastewater filter press depends largely on the capacity for the treatment, types of sludge and operational requirements. Essential components of the selection of the most appropriate press for redesigning are:

- Automation Level:Automation is here, and it is vital for a modern filter press to come equipped with automated features for efficient and reduced labor turning.

- Filtration Capacity: The first step in realizing your wastewater treatment goals is to know the volumes a filter press is capable of treating at any given time.

- Material Durability: The choice of a material that is resistant to corrosion and one that can serve for a longer period will ensure all equipment remains impact-resilient.

- Customization Options: Manufacturers who can provide tailored products for most industries, such as food and beverage, petrochemical, mining, and so on, have the vision of staying market-oriented and retaining repeat clients. Some manufacturers offer custom products which are the only effective solution.

Final Thoughts

The use of a high-end water filter press is an advantageous idea for plants that want to make headways in the run of clean water, lowered space for power homes and provision of pure water and which are obliged to observe strict laws. The article widens the scope of what an eco-friendly filter press means besides such forms of savings that range from the right management of sludge to the minimization of energy and chemical usage.

Organizations which are eager to follow the path of sustainability should not ignore the significance of the proper filtration technology. Responsible and regular use of natural resources is only possible with surpluses in the environment i.e. technological and other resources, and among these is the possibility of transforming domestic and industrial wastewater into ‘new water’ for the economy.