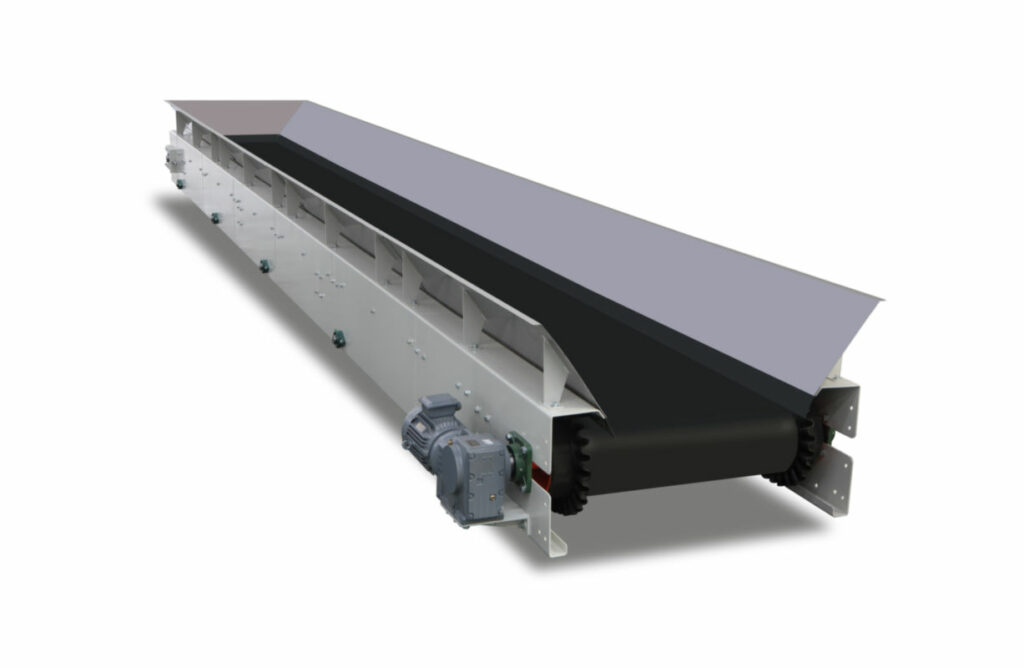

Belt conveyors are a common and effective solution for horizontal material transportation in factories and warehouses. Belt conveyors provide a continuous, efficient way to move items along production and assembly lines and handle bulk materials. Here are some key advantages of belt conveyors:

High Capacity Handling

One of the main advantages of belt conveyors is their high carrying capacity. Belt conveyors can transport materials at speeds ranging from a few feet per minute to thousands of feet per minute. This makes them ideal for moving large volumes of products or materials quickly and continuously.

Efficiency And Speed

Belt conveyors minimize material handling time and labor hours since they can move items continuously along a production line without needing manual intervention. They allow high-speed transportation of items compared to manual handling or roller conveyors.

Low Maintenance About Belt Conveyors

Properly designed belt conveyors have few moving parts and require little maintenance. Their operation is also straightforward without complex controls. Most belts just need periodic cleaning and belt tensioning to maintain optimal performance.

Excellent Flexibility Of Belt Conveyor

Belt conveyors are highly customizable and can be designed in any shape to fit your facility layout and material transport needs. They can accommodate curved sections, inclines, declines and switches to provide the required flexibility.

Good Tips Belt Conveyor Operates At Optimal Performance

The belt should have proper tension to provide enough friction for the pulleys to drive the belt while avoiding excessive tension that can damage the conveyor. Except this, China belt conveyor supplier also share other tips below.

Misaligned pulleys can cause uneven belt wear, slippage and belt damage.

Debris, dust and spills can build up on the belt over time and cause slippage, reduced efficiency and damage.

Lubricate bearings, rollers, reducers and other moving parts according to the manufacturer’s recommendations to minimize friction and extend part life.

Make sure bolts, screws, nuts and cleats securing conveyor components are tight.

As mentioned earlier, proper belt tension is important for optimal performance. Adjust belt tension if it becomes too loose or tight.