Abstract

The optimization of solid-liquid separation processes represents a significant operational goal across numerous industries, from mining and chemical manufacturing to wastewater treatment and food production. This document examines the multifaceted approach to improving efficiency with modern filter cloth. It explores the technical specifications of filter media, including material composition, weave architecture, and surface treatments, as fundamental determinants of filtration performance. The analysis posits that a systematic selection and management strategy, grounded in a deep understanding of slurry characteristics and process objectives, is paramount. Key performance indicators such as filtration cycle time, cake moisture content, filtrate clarity, and cloth lifespan are evaluated in relation to specific filter cloth properties. The discussion synthesizes theoretical principles with practical application, demonstrating that advancements in polymer science and textile engineering have yielded materials capable of delivering substantial enhancements in throughput and reductions in operational expenditure. The objective is to provide a comprehensive framework for engineers, plant managers, and technicians to diagnose inefficiencies and implement targeted solutions through the strategic use of advanced filtration media.

Key Takeaways

- Select material composition based on chemical, thermal, and abrasive process conditions.

- Match the filter cloth weave and pore size to your specific particle size distribution.

- Utilize surface treatments like calendering to enhance cake release and reduce binding.

- Proper installation and tensioning prevent leakage and premature cloth failure.

- A proactive cleaning schedule is vital for maintaining optimal permeability.

- Improving efficiency with modern filter cloth requires diligent monitoring and data analysis.

- Regularly evaluate new cloth technologies to stay ahead of operational challenges.

Table of Contents

- The 2025 Expert Checklist: 7 Actionable Tips for Improving Efficiency with Modern Filter Cloth

- 1. Master Material Selection: The Foundation of Filtration Performance

- 2. Decode the Weave: How Fabric Architecture Shapes Your Process

- 3. The Science of Separation: Pore Size, Permeability, and Particle Capture

- 4. Beyond the Weave: Leveraging Surface Finishes and Treatments

- 5. The Mechanics of a Perfect Seal: Proper Installation and Tensioning

- 6. The Art of Maintenance: Proactive Cleaning for Sustained Efficiency

- 7. From Data to Decisions: Monitoring and Analysis for Continuous Improvement

- Frequently Asked Questions (FAQ)

- A Final Perspective on Filtration Media

- References

The 2025 Expert Checklist: 7 Actionable Tips for Improving Efficiency with Modern Filter Cloth

The process of separating solids from liquids is a cornerstone of modern industry, a silent yet powerful operation that underpins everything from the purity of drinking water to the extraction of valuable minerals. At the heart of this process lies the filter press, and more specifically, its most critical component: the filter cloth. To view the filter cloth as a mere consumable, a simple textile, is to misunderstand its profound impact on operational efficiency, product quality, and economic viability. It is, in essence, the active interface where the separation physically occurs. Therefore, a deep, analytical engagement with this component is not merely beneficial; it is a requirement for any operation seeking to optimize its performance.

This exploration is designed to move beyond a superficial overview. We will journey into the intricate world of filtration media, approaching it not as a static object but as a dynamic tool. Our goal is to cultivate an empathetic understanding of the interplay between the filter cloth and the slurry it is tasked with dewatering. Think of it as a dialogue. The slurry, with its unique chemistry, particle size, and temperature, presents a set of challenges. The filter cloth, through its material, weave, and finish, offers a set of answers. The success of the operation hinges on how well these answers match the challenges. We will dissect the elements that constitute a high-performing filter cloth, providing a structured framework for making informed decisions that lead to tangible improvements in your filtration process.

1. Master Material Selection: The Foundation of Filtration Performance

The first and perhaps most defining choice in the journey toward improving efficiency with modern filter cloth is the selection of the base material. This decision forms the bedrock upon which all other performance characteristics are built. Choosing the wrong material is akin to building a house on a foundation of sand; no matter how well-designed the structure, it is destined to fail. The material must not only survive the process environment but thrive within it, maintaining its structural integrity and filtration characteristics over thousands of cycles.

The selection process is an exercise in matching the capabilities of a polymer to the demands of a specific industrial application. We must consider a trinity of factors: chemical compatibility, thermal stability, and abrasion resistance. A failure in any one of these areas can lead to rapid degradation of the cloth, resulting in process downtime, product contamination, and increased operational costs.

Chemical Resistance: Surviving the Slurry

Every industrial slurry has a unique chemical fingerprint. It may be highly acidic, strongly alkaline, or contain a cocktail of solvents and oxidizing agents. The filter cloth’s polymer must be functionally inert in this environment. Polypropylene, for example, exhibits outstanding resistance to a wide range of acids and alkalis, making it a versatile and widely used material (Sutherland, 2008). However, it can be susceptible to attack from certain hydrocarbon solvents.

Consider a scenario in a chemical plant where a slurry contains a high concentration of sodium hydroxide (a strong alkali) at a pH of 13. A filter cloth made from polyester (PET) would be a poor choice. Polyester is vulnerable to hydrolytic attack in highly alkaline conditions, meaning the polymer chains themselves are broken down by the caustic solution. The cloth would lose its tensile strength, become brittle, and fail prematurely. In contrast, a polypropylene (PP) cloth would remain unaffected, providing a long and reliable service life.

Conversely, if the process involves certain aromatic solvents, the roles might be reversed. The key is to obtain a comprehensive chemical analysis of your slurry, including not just the primary components but also any trace elements that could have a cumulative effect over time.

Thermal Stability: Withstanding the Heat

Filtration processes are often conducted at elevated temperatures to reduce the viscosity of the liquid phase, thereby speeding up the filtration rate. The filter cloth material must be able to withstand these temperatures without significant changes to its physical properties. Every polymer has a maximum continuous operating temperature. Exceeding this limit can cause the fibers to soften, stretch, or even melt. This leads to a loss of dimensional stability, a phenomenon known as plastic deformation. The pores of the cloth can become distorted, irreversibly altering its filtration characteristics.

Let's return to our material comparison. Polypropylene generally has a maximum operating temperature of around 90°C (194°F). For many applications, this is perfectly adequate. However, if a process requires filtration at 120°C (248°F), a standard polypropylene cloth would fail. In this case, one would need to consider a material with higher thermal stability, such as polyester (PET), which can often handle temperatures up to 130°C (266°F) or higher, depending on the specific grade. For even more extreme temperature requirements, specialized polymers like polyphenylene sulfide (PPS) or polytetrafluoroethylene (PTFE) might be necessary, though they come with a significant increase in cost.

Abrasion Resistance: Enduring the Solids

The solid particles within a slurry are not passive passengers. They can be sharp, hard, and highly abrasive. As the slurry is pumped into the filter press at high pressure, and as the filter cake is formed and later discharged, these particles scrape and grind against the fibers of the filter cloth. This constant mechanical wear can sever fibers, leading to a thinning of the cloth and the formation of holes.

Nylon (Polyamide, PA) is renowned for its exceptional abrasion resistance. Its smooth, tough fibers can withstand the friction from abrasive particles far better than many other polymers. This makes it an excellent choice for applications like mining and mineral processing, where slurries often contain hard, crystalline solids such as silica. While polypropylene offers good all-around performance, in a highly abrasive environment, a nylon cloth might offer double or triple the service life, more than justifying its potentially higher initial cost. The decision requires a careful cost-benefit analysis, weighing the price of the cloth against the cost of downtime for replacement.

The following table provides a comparative overview of common filter cloth materials, serving as a starting point for the selection process.

| Material | Chemical Resistance (Acids) | Chemical Resistance (Alkalis) | Max. Temp (°C) | Abrasion Resistance | Relative Cost |

|---|---|---|---|---|---|

| Polypropylene (PP) | Excellent | Excellent | 90 | Good | Low |

| Polyester (PET) | Good | Poor-Fair | 130 | Very Good | Medium |

| Nylon (PA) | Poor | Excellent | 110 | Excellent | Medium-High |

| Cotton (CO) | Poor | Good | 100 | Fair | Low-Medium |

| PTFE | Excellent | Excellent | 260 | Fair | Very High |

2. Decode the Weave: How Fabric Architecture Shapes Your Process

Once a suitable material has been selected, the next layer of complexity we must engage with is the architecture of the cloth itself—the weave pattern. If the material is the 'what', the weave is the 'how'. It dictates how the individual fibers are interlaced to form a fabric. This geometric arrangement has a profound influence on the cloth's strength, stability, permeability, and cake release properties. Thinking about the weave is not just a technical detail; it is about tailoring the physical structure of the filter medium to the specific needs of your particles and process.

There are three primary weave patterns used in filter cloth manufacturing: plain, twill, and satin. Each offers a unique combination of characteristics. Understanding them is like a chef understanding the difference between a coarse grind and a fine grind—the same ingredient behaves very differently depending on its structure.

Plain Weave: The Foundation of Simplicity

The plain weave is the most basic and common pattern. Each warp (longitudinal) yarn passes alternately over and under each weft (transverse) yarn. Imagine a simple checkerboard pattern. This creates a highly stable, tight, and strong fabric.

The primary advantage of a plain weave is its particle retention capability. The frequent interlacing of yarns creates a tortuous path for the liquid to follow, with relatively small and uniform pore openings. This makes it very effective at capturing fine particles and producing a very clear filtrate. However, this same characteristic can be a disadvantage. The tight structure can be more prone to blinding, where fine particles become lodged deep within the weave, making the cloth difficult toclean. Cake release can also be more challenging because the cake particles can interlock with the "knuckles" of the weave. A plain weave is often a good choice for primary filtration where filtrate clarity is the highest priority.

Twill Weave: The Balanced Workhorse

In a twill weave, the weft yarn passes over one or more warp yarns and then under two or more warp yarns, with a "step" or offset between rows. This creates the characteristic diagonal rib or "twill line" that you might recognize from a pair of denim jeans. Common variations include 2/1 twill or 3/1 twill.

The twill weave offers a compromise between the particle retention of a plain weave and the cake release of a satin weave. The yarns are less crimped than in a plain weave, resulting in a smoother surface and slightly larger pore openings. This configuration provides good flow rates and is less susceptible to blinding. The smoother surface facilitates better cake release, as the cake tends to sit more on the surface of the cloth rather than becoming embedded within it. Twill weaves are exceptionally versatile and are used in a vast range of applications, representing a robust, all-around choice for many slurries.

Satin Weave: The Champion of Cake Release

A satin (or sateen) weave takes this logic a step further. The defining feature is the presence of long "floats," where a yarn passes over four or more opposing yarns before interlacing. This creates a fabric surface that is incredibly smooth, flat, and lustrous.

The primary benefit of a satin weave is superior cake release. The exceptionally smooth surface minimizes the points where the filter cake can mechanically anchor itself. When the filter press opens, the cake often falls away cleanly and completely, reducing the need for manual scraping and minimizing the stress on the cloth. This smooth surface also provides excellent resistance to blinding. The trade-off is that the long floats make the fabric less dimensionally stable and more susceptible to yarn slippage and abrasion damage compared to plain or twill weaves. The pore structure is also less uniform. Satin weaves are the preferred choice for processes involving very fine, sticky, or slimy solids where cake discharge is the main operational bottleneck.

This table summarizes the key attributes of each weave pattern, helping to guide the selection based on process priorities.

| Weave Pattern | Particle Retention | Cake Release | Blinding Resistance | Stability / Strength | Typical Application |

|---|---|---|---|---|---|

| Plain | Excellent | Fair | Fair | Excellent | Fine particles, high filtrate clarity |

| Twill | Good | Good | Good | Good | General purpose, balanced performance |

| Satin | Fair | Excellent | Excellent | Fair | Sticky or fine cakes, difficult discharge |

Beyond these basic weaves, we encounter another layer of detail: the type of yarn used. Yarns can be monofilament, multifilament, or spun staple.

- Monofilament yarns are single, continuous extruded filaments, like a fishing line. They create a very smooth, two-dimensional surface with uniform pores, offering the best possible cake release and resistance to blinding.

- Multifilament yarns consist of many fine filaments twisted together, like a rope. They provide greater strength and flexibility.

- Spun Staple yarns are made from shorter fibers spun together, much like cotton or wool thread. They have a fuzzy, three-dimensional surface that is excellent for capturing very fine particles through depth filtration but can be very difficult to clean.

Often, a modern filter cloth will be a hybrid, using monofilament yarns in one direction and multifilament in the other to achieve a balance of properties. For instance, a monofilament/multifilament satin weave can offer the cake release of a monofilament with the strength and stability of a multifilament, representing a sophisticated solution for challenging applications.

3. The Science of Separation: Pore Size, Permeability, and Particle Capture

Having chosen a material and a weave, we now arrive at the microscopic heart of the filtration process: the interplay between the cloth's pores and the slurry's particles. This is where the actual separation happens. The two most important metrics governing this interaction are pore size and permeability. While related, they are not the same, and understanding the distinction is fundamental to improving efficiency with modern filter cloth.

Think of it this way: pore size is about the size of the openings, while permeability is about the ease with which fluid can flow through them. A cloth could have large pores but low permeability if the path through the cloth is very long and convoluted. Conversely, a cloth with smaller pores could have higher permeability if the path is short and direct.

Pore Size and the Mechanism of Cake Formation

The nominal pore size rating of a filter cloth refers to the size of the largest particle that can pass through it. However, the process of filtration in a filter press is not simple sieving, like using a colander to drain pasta. Instead, it relies on a principle called "bridge formation" or "cake filtration."

When the slurry first enters the press, some of the finest particles may indeed pass through the cloth along with the liquid, resulting in a cloudy initial filtrate. This is a normal and even necessary part of the cycle. Quickly, the larger particles in the slurry begin to bridge across the openings of the filter cloth. They form a preliminary layer, a "pre-coat," directly on the surface of the fabric. This initial layer of solids now becomes the actual filter medium. The pores of this newly formed cake are much finer than the pores of the cloth itself.

As filtration continues, this cake of solids builds up, and it is this cake that performs the bulk of the separation, capturing even the finest particles and yielding a crystal-clear filtrate. The role of the filter cloth, therefore, is not to capture every particle, but to act as a stable support structure for the filter cake to build upon.

What does this mean for selecting a pore size? It means you do not necessarily need a cloth with a pore size smaller than your smallest particle. In fact, choosing a cloth that is too tight can be counterproductive. A very tight cloth will have low permeability, leading to slow flow rates and long cycle times. It will also be highly susceptible to blinding, as fine particles become deeply wedged in the small pores. The ideal cloth has pores that are just small enough to allow for rapid and effective bridge formation by the solids in your specific slurry. A general rule of thumb is to select a cloth that will initially allow some fines to pass, as this is a sign that the cloth is open enough to provide good flow rates.

Permeability: The Key to Throughput

Permeability is a measure of how easily a fluid can flow through a porous medium under a given pressure differential. In the context of filter cloth, it is typically measured in cubic feet per minute per square foot (CFM/ft²) at a standard pressure drop (e.g., 0.5 inches of water). A higher CFM rating indicates higher permeability.

High permeability is directly linked to shorter filtration cycle times. A cloth that allows the liquid to pass through more easily will dewater the slurry faster, increasing the throughput of the filter press. This is a direct driver of operational efficiency. If you can process more batches in a single shift, the productivity of your entire operation increases.

The permeability of a cloth is determined by a combination of factors we have already discussed: the type of yarn (monofilament yarns generally yield higher permeability than spun yarns), the weave pattern (satin weaves tend to be more permeable than plain weaves), and the yarn density. The manufacturer's skill in creating a fabric that balances the required pore size with the maximum possible permeability is a hallmark of a quality filter cloth. When evaluating options, you should always request the permeability rating (CFM) as it is a more direct indicator of potential flow rate than pore size alone.

Imagine you are trying to empty a crowded stadium. You could have everyone exit through a few very large gates (high pore size) or many smaller gates (low pore size). Permeability is like the overall efficiency of the evacuation. The arrangement, number, and accessibility of the gates (the weave and yarn structure) determine how quickly people (the liquid) can exit, regardless of the exact size of each individual gate. Your goal is to find the cloth that evacuates the liquid from your slurry as quickly as possible while still reliably retaining the solids. This often involves a degree of trial and error, but starting with a solid understanding of these principles gives you a rational basis for your experimentation.

4. Beyond the Weave: Leveraging Surface Finishes and Treatments

The performance of a filter cloth is not solely defined by its base material and weave. A critical, and often overlooked, aspect of improving efficiency with modern filter cloth lies in the application of specialized surface finishes and treatments. These post-weaving processes modify the surface characteristics of the fabric to enhance specific properties, most notably cake release, resistance to blinding, and dimensional stability. Think of these treatments as adding a final layer of polish and functionality to an already well-constructed tool.

These finishes are not mere afterthoughts; they are integral to tailoring a cloth for a specific, often challenging, application. A process struggling with sticky filter cakes or rapid blinding may not need a completely different cloth material or weave, but rather an existing cloth enhanced with the correct finish.

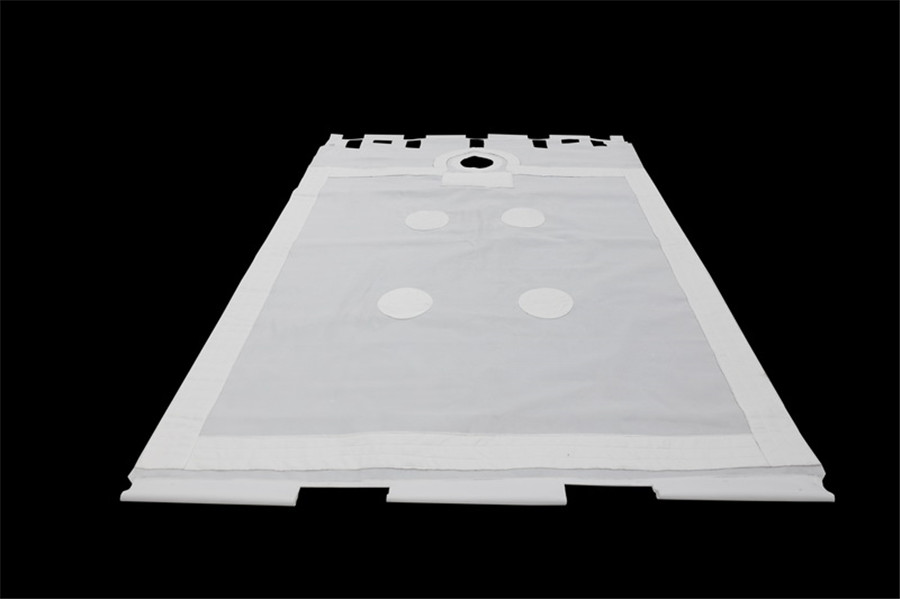

Calendering: Creating a Smoother Path

One of the most common and effective treatments is calendering. In this process, the filter cloth is passed between large, heated rollers under high pressure. This action flattens the yarns and partially closes the interstices of the weave, creating a smoother, less permeable, and more paper-like surface.

The primary benefit of calendering is a dramatic improvement in cake release. The smooth, glazed surface offers fewer anchor points for the filter cake to adhere to. When the press opens, the cake is much more likely to fall away cleanly and intact. This reduces the need for manual scraping, which in turn extends the life of the cloth and shortens the time between cycles.

Furthermore, by creating a more two-dimensional surface, calendering helps to keep the filtered particles on the surface of the cloth rather than allowing them to penetrate deep into the weave. This significantly improves the cloth's resistance to blinding. A calendered finish is particularly effective for slurries containing very fine or irregularly shaped particles that have a high tendency to blind a standard cloth. There are different degrees of calendering (light, medium, heavy), allowing for fine-tuning of the trade-off between cake release and permeability. Heavy calendering provides the best release but also the lowest permeability, so the choice must align with the overall process goals.

Heat Setting: Locking in the Structure

Heat setting, also known as thermosetting, is a process applied to thermoplastic fabrics like polypropylene and polyester. The cloth is heated to a temperature just below its melting point while being held under tension. This process relaxes the internal stresses within the synthetic fibers that were introduced during the weaving process.

The result is a fabric with excellent dimensional stability. A heat-set cloth will resist shrinking, stretching, or warping when exposed to the high pressures and temperatures of the filtration cycle. This stability is vital for maintaining a consistent and reliable fit on the filter plate. A cloth that shrinks can become overly tight, putting stress on the plate and the cloth's seams. A cloth that stretches can become loose, leading to wrinkling, poor cake formation, and leakage around the sealing edges. By locking the weave structure in place, heat setting ensures that the cloth's filtration characteristics remain consistent throughout its service life. Nearly all high-quality synthetic filter cloths undergo some form of heat setting.

Specialized Chemical Treatments

Beyond mechanical finishes, a range of chemical treatments can be applied to impart specific properties. For example, antistatic treatments can be applied for applications involving dry powders or solvents where a buildup of static electricity could pose a safety hazard. Hydrophilic (water-attracting) or hydrophobic (water-repelling) treatments can also be used to modify the surface energy of the fibers, which can influence how the cloth interacts with the liquid and solid phases of the slurry.

For instance, in a process where a non-aqueous solvent needs to be separated from a solid, a cloth with an oleophilic (oil-attracting) surface might improve the wetting of the cloth and the initial flow of the filtrate. These treatments are highly specialized and are typically developed in collaboration with a knowledgeable filter cloth manufacturer to solve a specific process problem. When faced with a particularly stubborn filtration challenge, it is always worth asking about the availability of such advanced treatments. Exploring a curated selection of specialized filter media can reveal options tailored for these unique situations.

5. The Mechanics of a Perfect Seal: Proper Installation and Tensioning

A filter cloth, no matter how technologically advanced, cannot perform optimally if it is not installed correctly on the filter plate. Improper installation is a frequent source of inefficiency, leading to problems that are often misdiagnosed as issues with the cloth itself. The goals of installation are to ensure a leak-free seal around the edges of the plate, to provide a smooth and even surface for cake formation, and to prevent premature mechanical damage to the cloth.

This phase of the process demands precision and attention to detail. It is a mechanical task, but one that has a direct and significant impact on the chemical and physical process of filtration. An error here can undermine all the careful work done in selecting the right material, weave, and finish.

Ensuring a Clean and Secure Fit

Before a new cloth is installed, the filter plate must be thoroughly cleaned. Any residual cake, scale, or debris on the plate surfaces, particularly on the sealing edges, must be removed. These residues can prevent the cloth from lying flat, creating channels for the slurry to bypass the filter medium. This results in "edge leakage," where unfiltered slurry seeps out between the plates, leading to a loss of product, a messy work environment, and a lower overall capture efficiency.

The cloth must be positioned on the plate so that it is centered and aligned correctly. The feed-neck or barrel-neck of the cloth must be securely attached to the feed port of the plate. Different filter presses use different attachment methods, from simple zip-ties to more sophisticated locking collars. Whatever the method, the connection must be tight and secure to prevent slurry from leaking behind the cloth. If slurry gets between the cloth and the plate, it can balloon the cloth, put immense stress on the fabric, and cause catastrophic failure.

The Importance of Correct Tension

Once positioned, the cloth must be properly tensioned. A cloth that is too loose will wrinkle under the pressure of filtration. These wrinkles create deep crevices where the cake will be thicker and wetter than in other areas. They also create stress points where the cloth can flex and chafe, leading to premature mechanical failure. Furthermore, wrinkles on the sealing edge will inevitably lead to leakage.

A cloth that is too tight is equally problematic. Excessive tension can stretch the pores of the weave, altering the cloth's filtration characteristics. It puts constant stress on the fibers and seams, which can lead to tearing, especially around the attachment points or the barrel neck. Over-tensioning can also physically damage the filter plate itself over time.

The correct tension is "drum-tight" but not stretched. The cloth should be smooth and flat against the drainage surface of the plate, with no visible wrinkles or sagging. Achieving this requires a systematic approach, often involving working from the center of the plate outwards, smoothing the cloth as it is secured. For certain types of installations, particularly on large plates, specialized tools may be used to apply even and consistent tension. Training operators on the correct "feel" for proper tension is a valuable investment in extending cloth life and ensuring process consistency.

Pre-use Conditioning

For some applications, particularly with new cloths, a pre-use conditioning cycle can be beneficial. This might involve running a cycle with just water or with a very dilute slurry. This allows the cloth to settle into its final position on the plate under pressure and can help to wet the fibers, which can improve initial filtration performance. It also serves as a final check to ensure that there are no leaks before introducing the full-strength process slurry. Taking the time to perform these mechanical steps with care and precision is not a chore; it is an active step in improving efficiency with modern filter cloth, ensuring that the advanced media you have selected can deliver its full potential.

6. The Art of Maintenance: Proactive Cleaning for Sustained Efficiency

A filter cloth does not have an infinite lifespan. Its performance will inevitably degrade over time due to a combination of mechanical wear and, more significantly, a gradual loss of permeability. This loss of permeability is caused by blinding and plugging—the progressive clogging of the cloth's pores with fine particles, chemical precipitates, or biological growth. A proactive and intelligent cleaning regimen is therefore not just about housekeeping; it is a fundamental strategy for maximizing the effective life of the cloth and maintaining consistent, efficient filtration.

Moving from a reactive cleaning schedule (cleaning only when the cycle time becomes unacceptably long) to a proactive one (cleaning at regular, predetermined intervals) can yield substantial benefits in throughput and cloth longevity. The goal is to remove the contaminants that blind the cloth without causing damage to the fibers or the weave structure.

Understanding the Enemy: Types of Blinding

To effectively clean a cloth, one must first understand what is clogging it. There are several forms of blinding:

- Surface Blinding: Particles, especially sticky or gelatinous ones, form a relatively impermeable film on the surface of the cloth. This is often the easiest type to address.

- Depth Blinding: Fine particles penetrate into the yarn structure itself, becoming lodged between the individual filaments of a multifilament or spun yarn. This is more difficult to remove.

- Chemical Blinding (Scaling): Minerals from the process water or slurry, such as calcium carbonate or calcium sulfate, precipitate out of solution and form a hard scale within the fabric. This happens when there are changes in temperature, pressure, or pH.

- Biological Blinding (Biofouling): In applications like wastewater treatment, microorganisms can grow on and within the cloth, creating a layer of slime that severely restricts flow (Razali et al., 2023).

Diagnosing the type of blinding is the first step. A visual inspection can be revealing. A slimy feel suggests biofouling, while a hard, crusty deposit points to chemical scaling. A microscopic examination of a used cloth sample can provide definitive answers.

Mechanical Cleaning Methods

The most common cleaning method is a high-pressure water wash. Most modern filter presses are equipped with automatic cloth washing systems that spray the cloths with water as the plate stack is opened. This is very effective for removing surface blinding and loose particles.

The key to effective high-pressure washing is to use the right pressure and nozzle type. The pressure should be high enough to dislodge the contaminants but not so high that it damages the fibers of the cloth. A fan-jet nozzle is generally preferred over a needle-jet, as it distributes the force over a wider area, providing a "scraping" action rather than a piercing one. The spray bar should traverse the entire surface of the cloth to ensure even cleaning.

For cloths that have been removed from the press, off-line washing can be performed. This can involve soaking the cloths in cleaning solutions followed by pressure washing.

Chemical Cleaning: A Targeted Approach

When mechanical cleaning is insufficient, chemical cleaning is required. This is particularly true for chemical scaling and stubborn organic or biological fouling. The choice of chemical is entirely dependent on the nature of the contaminant and the chemical resistance of the filter cloth material. Using the wrong chemical can instantly destroy a set of cloths.

Here is a general guide:

- For Mineral Scale (e.g., Calcium Carbonate): An acid wash is typically effective. A dilute solution of hydrochloric acid (muriatic acid) or sulfamic acid can be used to dissolve the scale. The concentration and contact time must be carefully controlled. This method should never be used on a nylon (PA) cloth, as nylon has poor resistance to acids.

- For Metal Oxides/Hydroxides (e.g., Iron): Stronger acids or specialized chelating agents may be needed. Oxalic acid is often effective for iron removal.

- For Organic and Biological Fouling: An alkaline wash, often combined with a surfactant or detergent, can break down fats, oils, and biological matter. Sodium hydroxide (caustic soda) and sodium hypochlorite (bleach) are commonly used. An alkaline wash should not be used on a polyester (PET) cloth, as it will be chemically attacked.

Chemical cleaning is a powerful tool, but it must be wielded with knowledge and care. Always perform a chemical soak test on a small sample of the filter cloth before treating an entire set. After any chemical wash, the cloths must be thoroughly rinsed with clean water to remove all residual cleaning chemicals, which could otherwise contaminate the process or damage the cloth. A well-designed cleaning program, alternating between mechanical and targeted chemical washes, is a cornerstone of maintaining high permeability and improving efficiency with modern filter cloth over the long term.

7. From Data to Decisions: Monitoring and Analysis for Continuous Improvement

The final element in our expert checklist for improving efficiency with modern filter cloth is the establishment of a system for monitoring, data collection, and analysis. In the absence of data, decisions about cloth selection, replacement, and cleaning are based on guesswork, tradition, or subjective "feel." A data-driven approach transforms filtration from an art into a science, enabling continuous improvement and process optimization.

The filter press operation generates a wealth of data during every cycle. Capturing and analyzing this information provides direct feedback on the performance of the filter cloth and the overall health of the process. This allows you to identify trends, diagnose problems early, and make informed, evidence-based decisions.

Key Performance Indicators (KPIs) to Track

To build a useful picture of your process, you should consistently track a few key metrics. Modern automated filter presses often log this data automatically, but even in manual operations, it can be recorded with minimal effort.

-

Filtration Cycle Time: This is the most fundamental KPI. It is the total time from the start of the feed pump to the end of the filtration phase. An increase in cycle time is the most common indicator that the filter cloth is beginning to blind and lose permeability. Plotting the cycle time over the number of cycles on a new cloth provides a clear visual representation of its performance decay curve.

-

Filtrate Solids Content (Clarity): At the beginning of a cycle and immediately after a cloth change, the filtrate may be slightly cloudy. However, it should clear up quickly. The clarity of the filtrate during the main part of the cycle should be monitored. A sudden or gradual increase in filtrate solids can indicate a hole in the cloth, a leaking seal, or a cloth that is no longer suitable for the application. This can be measured qualitatively by eye or quantitatively using a turbidity meter.

-

Filter Cake Moisture Content: The primary goal of most filtration operations is to produce the driest possible cake. The moisture content of the cake should be measured regularly. An increase in cake moisture can indicate poor cake formation (perhaps due to a wrinkled cloth), incomplete filtration, or a blinded cloth that is preventing the final portion of liquid from passing through.

-

Feed Pressure vs. Flow Rate: The relationship between the pressure applied by the feed pump and the resulting flow rate of the filtrate is a direct measure of the total resistance in the system. As the cloth blinds and the cake builds, this resistance increases. Plotting the pressure and flow curves for each cycle can provide a detailed diagnostic fingerprint of the filtration process. A rapid pressure rise with low total flow suggests a blinded cloth.

Using Data to Drive Decisions

Once you begin collecting this data, you can use it to make intelligent operational decisions.

-

Optimizing Cloth Replacement: Instead of replacing cloths on a fixed schedule (e.g., every three months), you can replace them based on performance. You might set a threshold, for example, that cloths will be replaced when the average cycle time increases by 25% from its baseline. This ensures you are getting the maximum useful life out of each cloth without sacrificing process efficiency. It also prevents you from running a cloth to the point of catastrophic failure.

-

Evaluating New Cloths: When you trial a new type of filter cloth, a data-driven approach allows for an objective comparison. You can install the trial cloth on one press and keep the standard cloth on another, then compare the KPIs (cycle time, cake moisture, etc.) over a period of several weeks. This provides quantitative evidence to determine if the new cloth offers a real improvement and a justifiable return on investment. This is the essence of improving efficiency with modern filter cloth—using evidence to guide technical evolution.

-

Fine-Tuning the Cleaning Schedule: By observing the cycle time trend, you can determine the optimal interval for chemical cleaning. You might find that a light acid wash after every 500 cycles keeps the cycle time stable, preventing the need for a much more aggressive and time-consuming cleaning later on. Data allows you to move from remedial cleaning to preventative maintenance.

Embracing a culture of data collection and analysis elevates the management of your filtration system. It empowers operators and engineers to understand the subtle dynamics of their process and to make proactive adjustments that lead to significant and sustained gains in efficiency, reliability, and profitability.

Frequently Asked Questions (FAQ)

1. How often should I replace my filter cloth? There is no universal answer, as replacement frequency depends on the abrasiveness of your slurry, your operating pressure, the effectiveness of your cleaning regimen, and your process efficiency targets. A data-driven approach is best. Monitor KPIs like filtration cycle time and cake moisture. When cycle times consistently exceed a predetermined baseline (e.g., 25% longer than with a new cloth) despite cleaning, it is likely time for a replacement. Replacing cloths based on performance data is more efficient than relying on a fixed calendar schedule.

2. What is the difference between monofilament and multifilament filter cloth? A monofilament yarn is a single, solid strand of polymer, like a fishing line. A multifilament yarn is composed of many fine strands twisted together, like a thread. Cloths made from monofilament yarns have a smoother surface, which provides excellent cake release and resistance to blinding. Cloths made from multifilament yarns are generally stronger and more flexible but can be more prone to particles getting trapped within the yarn bundle.

3. Why is my filter cake wet and sticky? High cake moisture can be caused by several factors. Your filter cloth may be blinded, preventing the final dewatering stage from being effective. The wrong weave, such as a plain weave for a sticky substance, could be holding onto the cake. A satin weave is often better for such applications. Additionally, process parameters like insufficient filtration time, low feed pressure, or the absence of a "cake squeeze" cycle (if your press has membrane plates) can result in a wet cake.

4un. Can I use one type of filter cloth for different slurries? While possible, it is generally not recommended if the slurries have significantly different characteristics (e.g., different pH, particle size, or temperature). A filter cloth is a specialized tool. A cloth optimized for a high-temperature, acidic slurry will likely not perform well with a cold, abrasive, alkaline slurry. Using a single "general purpose" cloth for multiple, distinct applications often leads to compromised performance in all of them. It is more efficient to match the cloth to each specific process.

5. My filtrate is cloudy. What is the cause? A cloudy filtrate can be caused by several issues. If it only occurs at the very beginning of the cycle, it might be a normal part of the bridge formation process. If it persists, it could indicate a hole or tear in the cloth, a poor seal around the barrel neck or edges of the plate, or a cloth with a pore size that is too large for your particle distribution, preventing an effective filter cake from forming.

6. What is "blinding" and how can I prevent it? Blinding is the clogging of the filter cloth's pores with particles, which reduces its permeability and slows down filtration. It can be prevented by selecting the right cloth (e.g., a monofilament or satin weave with a calendered finish for fine particles) and implementing a regular, effective cleaning schedule. High-pressure water washing can remove surface blinding, while targeted chemical washes are needed to remove scaling or deep-set organic fouling.

7. Does the color of a filter cloth matter? For the most part, the color of a filter cloth is incidental and related to the natural color of the polymer or any stabilizers added during manufacturing (e.g., polypropylene is naturally white). However, in some industries like food processing or pharmaceuticals, specific colors (like blue) are sometimes used to provide a visual contrast, making it easier to spot any potential contamination. From a filtration performance perspective, the material, weave, and finish are the factors that matter, not the color.

A Final Perspective on Filtration Media

The engagement with filtration technology is a continuous dialogue between industrial need and material innovation. The modern filter cloth is not a simple commodity but a piece of precision-engineered equipment. The path to enhanced efficiency is paved with a nuanced understanding of its material science, its structural architecture, and its lifecycle within the demanding environment of the filter press. By moving beyond a superficial checklist and adopting a more analytical, data-informed perspective, operators and engineers can transform the filter cloth from a passive component into an active lever for process improvement. The principles of careful selection, meticulous installation, proactive maintenance, and diligent monitoring work in concert to unlock the full potential of any solid-liquid separation system. This approach ensures that the filter press operates not just as a machine, but as an optimized, reliable, and highly efficient system that contributes directly to the economic and operational health of the entire enterprise.

References

Jung, D.-W., Kim, J., Kim, H., Jung, H., Choi, W., & Park, H. (2024). A comprehensive review of membrane-based water filtration techniques. Applied Water Science, 14(7), 169.

Matter, C. G. (2024). Membrane filtration (micro and ultrafiltration) in water purification. In Handbook of Water and Used Water Purification. Springer. https://doi.org/10.1007/978-3-319-78000-9_3

Peter, M. (2023). Membrane filtration. In Oxford Research Encyclopedia of Global Public Health. Oxford University Press.

Razali, M. C., Wahab, N. A., Sunar, N., & Shamsudin, N. H. (2023). Existing filtration treatment on drinking water process and concerns issues. Membranes, 13(3), 285. https://doi.org/10.3390/membranes13030285

Saha, U. K. (2025). Household water treatment: Mechanical filtration methods and devices (Publication No. B1523). University of Georgia Extension.

Sutherland, K. (2008). Filters and filtration handbook (5th ed.). Butterworth-Heinemann.

HydroGroup®. (2019). Filtration: Fundamentals and processes.