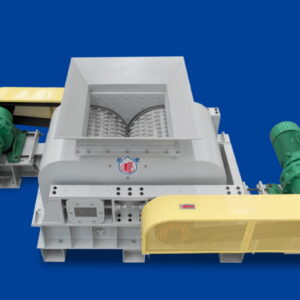

Product Description

What is an agitator?

Jingjin’s independently developed variable cross-section and variable inclination agitator (propeller type) is mainly used for mixing, decomposing and reacting materials. The agitator is mainly axial flow direction, which saves 50% of power compared with ordinary flat paddle agitation. Jingjin Technology Center is equipped with Siemens fluid simulation software, which can simulate and analyze various paddle shapes and select suitable agitators for different materials.

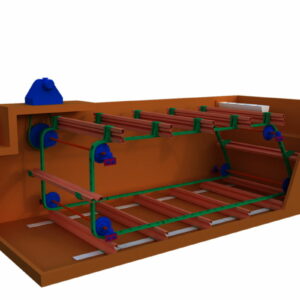

Dynamic simulation analysis of agitators through Siemens CCM software: Jingjin can perform three-dimensional flow field and cross-sectional flow field analysis for some special industries, which can more intuitively see the flow of materials in the reactor and determine the optimal solution more accurately and quickly. It can make more appropriate selections for the stirring effect, power, speed and stirring form of materials.

Classification of stirring paddles of agitators

1. Three-blade or four-blade flat plates are mainly used for slurry to prevent material precipitation.

2. Six-blade disc paddles are mainly used to disperse and stir gases in solutions.

3. Variable cross-section and variable inclination paddles are mainly used for mixing, decomposing and reacting materials

4. Frame-type stirring paddles are mainly used for materials with relatively high viscosity to prevent material precipitation

Comparison of Jingjin’s mixers with other products

1. The mixer frames made by Jingjin are all welded and formed with carbon structural steel, which is stronger than the old cast iron material.

2. The maximum processing length of Jingjin’s stirring shaft is 13 meters, and the flange and hub parts can be processed as a whole to ensure concentricity. Some manufacturers have insufficient processing capacity and make the stirring shaft into multi-section type. The disadvantage is that the shaft end swings a lot.

3. Carbon steel rubber-lined stirring shaft is suitable for strong acid environment. The stirring shaft is lined with 8-10 mm thick vulcanized butyl rubber to isolate the main shaft from strong acid. It is suitable for various materials and the temperature is below 90.

Application fields of agitators

Applicable to sewage, chemical, pharmaceutical, mining, metallurgy and other industries.