Product Description

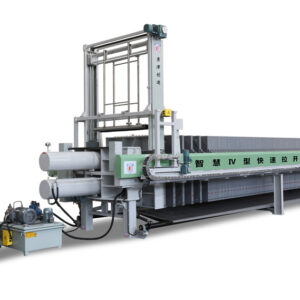

What Is Dead Weight Hydraulic Filter Press?

The Dead Weight Hydraulic Filter Press is utilized in industries such as chemical, pharmaceutical, food, and wastewater treatment to facilitate solid-liquid separation. This type of filter press utilizes hydraulic pressure to compress a set of plates that are equipped with filter media, such as filter cloths, to achieve this separation. The term “dead weight” refers to the application of force or weight to the hydraulic system, which enhances the efficiency and effectiveness of the filtration process. It is worth noting that dead weight hydraulic filter presses typically possess a higher filtration capacity compared to other filter press types.

Dead Weight Hydraulic Filter Press From

JINGJIN

- Established in 1998, Jinjiang Environmental Protection Inc. aims to be a one-stop-shop for environmental protection services. The company provides a range of solutions, including manufacturing filter equipment, integrated filtration technology, and contracting and managing environmental protection projects.

- Additionally, the company serves as the vice-president unit of China Environmental Protection industry Association and is the main drafter of national standards for filter press and filer plates.

- The company’s filter press production capacity and sales volume have remained the largest in the world for twelve consecutive years, selling to 123 countries and regions.

JINGJIN As Leading Global Service Provider

JINGJIN aims to realize the Chinese dream by becoming a world leader in environmental protection services. Its mission of “protecting the environment and beautifying China” and eco-friendly strategy of “turning wastewater into pure water and sludge into resources” provides a comprehensive solution for environmental protection while promoting economic development. The ultimate goal is to leave a cleaner environment with clean water and blue skies as a legacy for future generations.

JINGJIN Introduced A Complete Set Of German Equipment

JINGJIN is committed to developing a career centered around energy conservation and environmental protection. It provides consumers with cost-effective products and high quality professional services.

- In order to achieve better filtering requirements, Jingjin introduced a complete set of German filter cloth production line and tehnology.

- By virtue of jingjin’s 27 years of filtering experiende, the heavy German rapier looms weave the thinnest silk threads into filter cloth of high density and different hole patterns by using 0.3-3.5 tons beating-up force after each weft across warp.

- Under same area the filtration holes of JIngjin filter cloth are 50% more than other iflter cloth, which improve the filtration speed greatly.

- The filter cloth was woven under constant temperature and humidity ,which eliminate the fabric burrs caused by static electricity.

The crucial aspect is the ability of the monofilament filter cloth to facilitate automatic detachment of the filter cakes, thereby resolving a long-standing issue.

Quick Details

Supply Ability

- Supply Ability:10000 Set/Sets per Year

Packaging & Delivery

- Packaging Details:Seaworthy packing

- Port: Tianjin

- Lead Time: 15days from prepayment