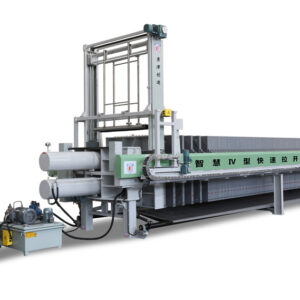

chamber filter press

- Individual adaptation to fulfill different process requirements and specific customer requirements

- The high degree of configuration and maximum flexibility

- Compact and robust design for a flawless and reliable filtration operation

- High level of security through the use of the latest security techniques

- Good price/performance ratio

Product Description

chamber filter press-High-efficiency filter press

A chamber filter press is a type of filter press popular in various industries for solid-liquid separation. It is commonly popular in wastewater treatment plants, mining operations, chemical industries, and food processing plants. Which forces the liquid portion to pass through the filter cloth while retaining the solid particles within the chambers.

The basic structure of a chamber filter press consists of a series of filter plates with filter cloths, which are arranged alternately with solid plates. Our product’s plates are typically made of materials such as polypropylene, cast iron, or stainless steel, depending on the application and the nature of the material being filtered. Each plate has a central cavity or chamber where the solids accumulate during the filtration process.

Jingjin chamber filter press advantage

- High Filtration Efficiency: We utilize advanced filtration technologies, such as precise filter cloth alignment and optimized plate design, to achieve efficient and effective filtration results.

- Robust and Durable Construction: The filter plates are typically made from high-strength polypropylene or other corrosion-resistant materials.

- Excellent Sealing Performance: Jingjin chamber filter presses equip with reliable sealing systems that prevent leakage and ensure consistent pressure application throughout the filtration process.

- User-Friendly Operation: The equipment is equipped with automated or semi-automated control systems that simplify operations and reduce manual intervention.

- Wide Range of Applications: Jingjin offers customization options to tailor the filter presses to specific process requirements.

Filtration Principle

The filter cloth acts as a medium that allows the liquid to pass through while retaining the solids. The result is the formation of filter cakes within the chambers and the collection of filtrate, enabling effective solid-liquid separation.

- Filtration: The chamber filter press applies pressure to the slurry by either hydraulic or mechanical means. This pressure forces the liquid portion of the slurry to pass through the filter cloth while retaining the solid particles within the chambers.

- Cake Formation: As the liquid passes through the filter cloth, a layer of solid particles, known as the filter cake, forms on the surface of the cloth within each chamber.

- Filtrate Collection: The liquid portion of the slurry, called the filtrate, passes through the filter cloth and collects in a drainage system or collection channel.

- Cloth Cleaning: Over time, the filter cloths may become clogged with accumulated solids, reducing filtration efficiency. Periodic cleaning or replacement of the filter cloths is necessary to maintain the performance of the chamber filter press.

Applications of chamber filter press

- Wastewater Treatment: Chamber filter presses are popular in municipal and industrial wastewater treatment plants. This application helps in reducing the volume of sludge for disposal and achieving cleaner water.

- Mining and Minerals: In the mining industry, chamber filter presses are popular for dewatering mining slurries and recovering valuable minerals. They can separate solids from mining tailings, concentrate slurries, and other mining process streams. By removing water from the slurry, chamber filter presses facilitate the handling and disposal of solid waste. And enable the recovery of water and valuable minerals.

- Chemical Industry: Chamber filter presses help improve product quality, reduce waste, and enhance process efficiency in chemical manufacturing.

- Food and Beverage: The food and beverage industry utilizes chamber filter presses for different applications. Additionally, chamber filter presses help remove solids, particles, and impurities, ensuring product clarity and quality.