Automatic Dosing Machine

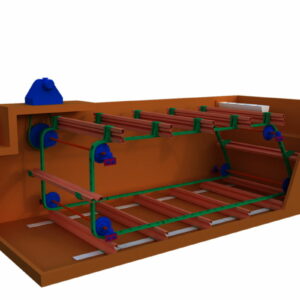

1. Three-compartment fully automatic dosing machine: mainly used for continuous dosing such as thickeners and concentrators.

2. Two-compartment fully automatic dosing machine: mainly used for conditioning tanks, such as intermittent dosing and instantaneous large dosage.

We provide product customization services.

Product Description

What is an automatic dosing machine?

An automatic dosing machine is an automated device designed for water treatment and other industrial processes. It can accurately, continuously and on demand add chemicals (such as coagulants, disinfectants, pH adjusters, etc.) to fluids (usually water). The use of such equipment is intended to maintain the efficient operation of the water treatment system and ensure that the water quality meets specific standards, such as removing pollutants, preventing corrosion, disinfecting or softening water quality.

Advantages of Jingjin automatic dosing machine compared to other manufacturers:

1. Agitators are set in all three boxes, and the dissolution time of the agent is longer and more complete. Some manufacturers only have stirring in the first two boxes.

2. A low-temperature heating device and a moisture-proof cover are set in the dry powder storage hopper to prevent the agent from absorbing moisture and becoming ineffective. Some manufacturers do not have them.

3. Some manufacturers do not have agitators in their storage tanks, which results in poor dissolution of the flocculants. On-site workers will remove the undissolved flocculants to prevent pipe and pump blockage, resulting in waste of flocculants.

Application areas of automatic dosing machines

1. Sewage treatment: The automatic dosing machine plays a key role in the sewage treatment process. It can automatically and accurately add flocculants, coagulants, disinfectants and other chemical agents to sewage to improve the efficiency and effect of sewage treatment.

2. Industrial circulating water treatment: In industrial circulating water systems, automatic dosing machines are used to add scale inhibitors, corrosion inhibitors, biocides and other agents to prevent scaling, corrosion and microbial growth of water pipes and equipment, and ensure the normal operation of the system.

3. Boiler water treatment: The automatic dosing machine is used in boiler water treatment systems to prevent scaling and corrosion in the boiler by adding deoxidizers, phosphates, alkaline agents, etc., and improve boiler operation efficiency and safety.

4. Drinking water treatment: In the process of drinking water treatment, automatic dosing machines are used to add disinfectants (such as chlorine, chlorine dioxide), pH adjusters, coagulants, etc. to ensure the safety and hygiene of drinking water.

5. Swimming pools and waterscape facilities: Automatic dosing machines are used in swimming pools and waterscape facilities to add disinfectants, pH adjusters and clarifiers to keep the water clean and safe.

6. Metallurgical industry: In the metallurgical industry, automatic dosing machines are used to add various treatment agents to improve the separation efficiency and metal recovery rate during ore flotation, smelting and refining.

7. Chemical industry: The chemical industry uses automatic dosing machines to add catalysts, stabilizers, pH adjusters, etc. during the production process to ensure the stability of chemical reactions and the control of product quality.

8. Pulp and paper industry: In the pulp and paper industry, automatic dosing machines are used to add chemicals such as bleaching agents, pulp enhancers, defoamers, etc. to improve pulp quality and production efficiency and reduce pollution during the production process.