Today we will provide a detailed comparison of the two, highlighting their differences and similarities, and helping readers make an informed decision when choosing a filter press.

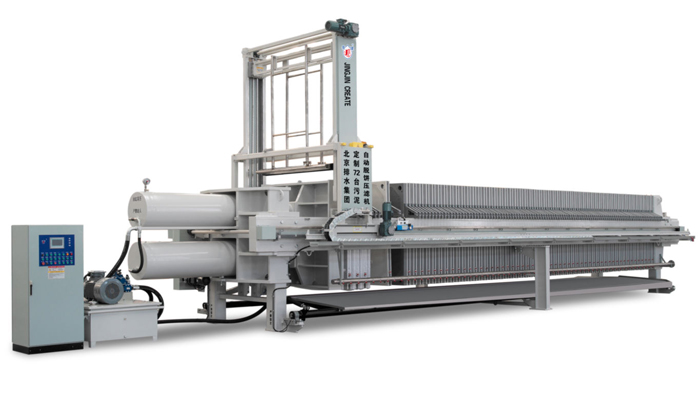

Filter presses are essential equipment in various industries, including chemical, pharmaceutical, and food and beverage. They are used to separate liquids and solids, and their efficiency and effectiveness play a crucial role in maintaining product quality and purity.

Among the different types of filter presses available, Plate and Frame Filter Press and Recessed Chamber Filter Press are two popular options. In this article, we will compare these two filter presses, focusing on their design, functionality, and applications.

Design and Construction

The design and construction of the Filter Press and Recessed Chamber Filter Press differ significantly. Plate and Frame Filter Press consists of a series of plates and frames that are stacked together to form a filter pack.

The plates are perforated, allowing the liquid to pass through while the solids are collected on the surface of the plates. The frames, on the other hand, are used to support the plates and maintain their spacing.

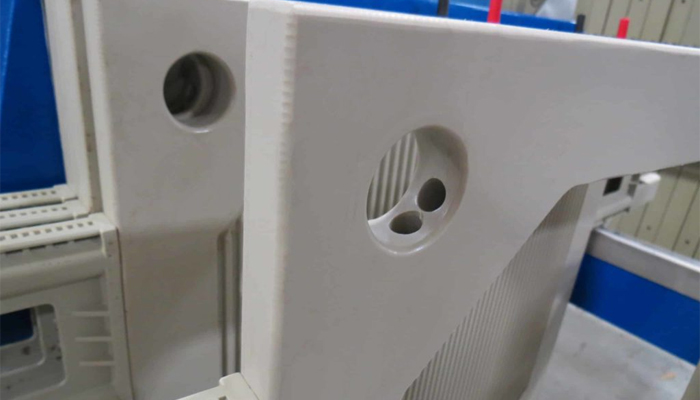

Recessed Chamber Filter Press, on the other hand, has a more complex design. It consists of a series of chambers that are recessed into a plate.

The chambers are designed to hold the solids, while the liquid flows through the plate and out of the chamber. The plate is then pressed to separate the solids from the liquid.

Functionality of Plate and Frame Filter Press and Recessed Chamber Filter Press

The functionality of the Plate Filter Press and Recessed Chamber Filter Press also differs. Plate and Frame Filter Press works by applying pressure to the filter pack.

Which causes the liquid to flow through the plates and leave the solids behind. The pressure is then released, and the solids are removed from the plates.

Recessed Chamber Filter Press, on the other hand, uses a different mechanism. The chambers are filled with solids, and the plate is pressed to separate the solids from the liquid. The liquid flows out of the chamber, leaving the solids behind.

Applications of Plate and Frame Filter Press

These two Filter Presses have different applications in various industries. Plate and Frame Filter Press is commonly used in the chemical, pharmaceutical, and food and beverage industries for tasks such as clarification, classification, and purification.

Recessed Chamber Filter Press, on the other hand, is commonly used in the chemical, petrochemical, and oil refining industries for tasks such as separation, purification, and dewatering.

Advantages and Disadvantages

Both the two Filter Press have their advantages and disadvantages. Plate and Frame Filter Press is easier to clean and maintain, and it can handle a wide range of particle sizes. However, it can be less efficient than the Recessed Chamber Filter Press, and it may require more filter aid.

Recessed Chamber Filter Press, on the other hand, is more efficient and can handle larger particle sizes. However, it can be more difficult to clean and maintain, and it may require more expensive filter aids.

Conclusion

In conclusion, Plate Filter Press and Recessed Chamber Filter Press are two distinct types of filter presses with different designs, functionalities, and applications.

While they share some similarities, they differ in several key aspects. Understanding the differences between these two filter presses can help industries decide. When to choose a filter press that meets their specific needs and requirements.

Plate and Frame Filter Presses and Recessed Chamber Filter Press have advantages and disadvantages, and industries must weigh these factors when deciding.

By considering efficiency, maintenance, and particle size, industries can choose the filter press that best meets their needs.