In the world of filtration, plate and frame filter presses vs. recessed chamber filter presses are two popular options. We will explore the key differences about them, and help you determine which one is best suited for your application.

Plate and Frame Filter Press:

A plate and frame filter press is a type of filter press. That uses a series of plates and frames to separate solids from liquids. The plates are arranged in a stacked formation, with each plate having a frame that holds a filter cloth.

The liquid to be filtered is pumped into the spaces between the plates, and the solids are collected on the filter cloths. The plates are then pressed together to remove the solids, and the filtered liquid is collected in a tank.

Plate and frame filter presses are popular in a variety of industries. Including chemical processing, food and beverage, and pharmaceuticals. They are known for their high filtration efficiency and ability to handle large volumes of liquid.

Recessed Chamber Filter Press:

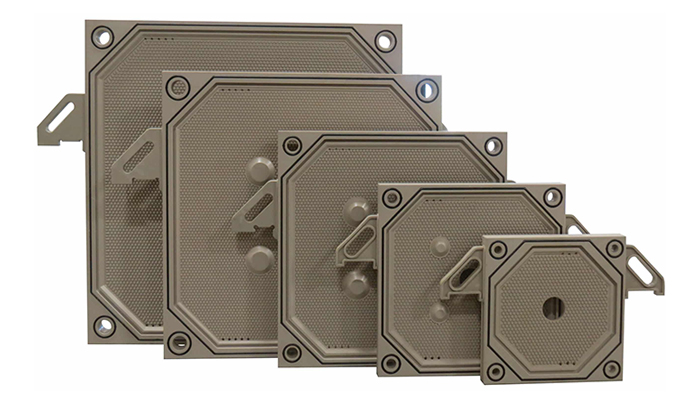

A recessed chamber filter press is a type of filter press that uses a recessed chamber to separate solids from liquids. The chamber is formed by a series of plates that are arranged in a stacked formation, with each plate having a recessed area in the center.

The liquid to be filtered is pumped into the recessed area, and the solids are collected on the surfaces of the plates. The plates are then pressed together to remove the solids, and the filtered liquid is collected in a tank.

Recessed chamber filter presses are commonly used in industries such as oil and gas, mining, and wastewater treatment. They are known for their ability to handle high-viscosity liquids and their compact design, which makes them ideal for use in smaller spaces.

Comparison of Plate and Frame Filter Press and Recessed Chamber Filter Press:

When it comes to choosing between a plate and frame filter press and a recessed chamber filter press, there are several factors to consider. Here are some key differences between the two systems:

Filtration Efficiency: Plate and frame filter presses are known for their high filtration efficiency. Making them ideal for applications where high-quality filtration is required. Recessed chamber filter presses, on the other hand, have a lower filtration efficiency, but they are better suited for applications where high-viscosity liquids are present.

Volume: Plate and frame filter presses are capable of handling large volumes of liquid. Making them ideal for applications where high-volume filtration is required. Recessed chamber filter presses, on the other hand, are better suited for applications where lower volumes of liquid need to be filtered.

Cost: Plate and frame filter presses are generally more expensive than recessed chamber filter presses, due to their more complex design and larger size.

Maintenance: Plate and frame filter presses require more maintenance than recessed chamber filter presses, as the plates and frames need to be regularly cleaned and replaced. Recessed chamber filter presses, on the other hand, require less maintenance, as the plates are designed to be self-cleaning.

Conclusion:

In conclusion, both plate and frame filter presses and recessed chamber filter presses have their advantages and disadvantages. Additionally, the choice between the two systems depends on the specific needs of your industry. Including the type of liquid being filtered, the volume of liquid, and the required filtration efficiency.

By understanding the key differences between these two systems. You can make an informed decision about which one is best suited for your application.