In the world of wastewater treatment and sludge management. This article will provide a comprehensive guide to membrane filter press apparatus, including their benefits, components, and maintenance tips.

Benefits of Membrane Filter Press Apparatus

Membrane filter press apparatus offers several advantages over traditional dewatering methods, including:

Improved efficiency: Membrane filter presses can achieve higher solid concentrations and lower water content, resulting in lower disposal costs and improved process efficiency.

Compact design: These machines are designed to be compact and space-saving, making them ideal for applications where space is limited.

Low energy consumption: Membrane filter presses operate at low pressures, reducing energy consumption and costs.

Simple operation: The automatic control system and easy-to-use design make it simple for operators to monitor and control the dewatering process.

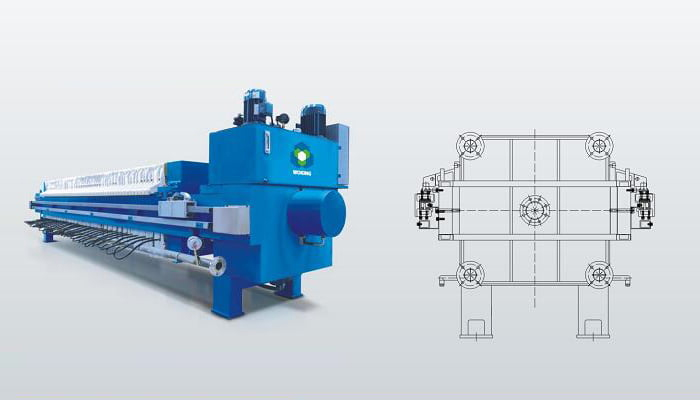

Components of a Membrane Filter Press Apparatus

A typical apparatus consists of several key components, including:

Filter membranes: These are the heart of the machine, responsible for separating solids from liquids. There are various types of membranes available, including polymer, ceramic, and composite materials.

Pressure plate: The pressure plate is responsible for applying pressure to the filter membranes, allowing for efficient dewatering.

Pump: The pump is used to circulate the liquid through the system and apply pressure to the filter membranes.

Control system: The control system monitors and controls the entire dewatering process, ensuring optimal performance and minimal downtime.

Maintenance Tips for Membrane Filter Press Apparatus

To ensure optimal performance and extend the lifespan of your apparatus, follow these maintenance tips:

Clean the filter membranes regularly: Cleaning the filter membranes is crucial to maintaining their performance and preventing clogging.

Inspect and replace worn-out components: Regularly inspect the pressure plate, filter membranes, and pump for signs of wear and tear. Replace them as needed to prevent downtime.

Monitor the control system: Ensure the control system is functioning properly and regularly check for any errors or alerts.

Perform routine maintenance on the pump: Regularly check the pump’s fluid level, pressure, and temperature to ensure it’s operating within safe parameters.

Conclusion

In conclusion, membrane filter press apparatus is a crucial component in wastewater treatment and sludge management. By understanding their benefits, components, and maintenance tips, operators can ensure optimal performance, minimize downtime, and extend the lifespan of their equipment.