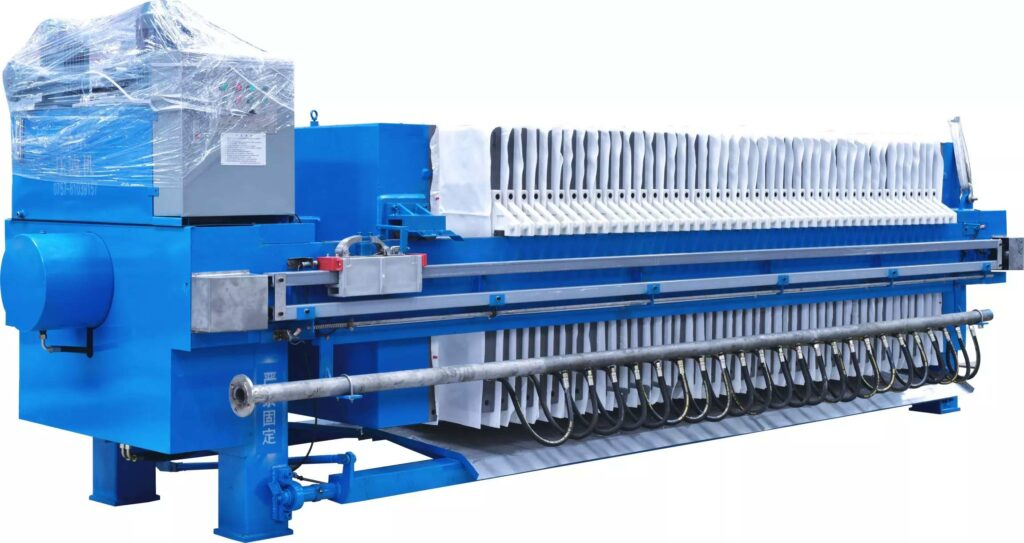

Jingjin filter presses are highly efficient filtration systems that offer a durable and reliable solution for various industries. Understanding the different types of the filter presses can help you choose the right system for your specific needs. In this article, we will explore the various types of filter presses and their applications.

Introduction

Jingjin filter presses are popular in various industries, such as chemical, food and beverage, pharmaceuticals, and mining. These filtration systems come in different types, each designed for a specific application. Understanding the different types of filter presses can help you choose the right system for your specific needs.

Types of Jingjin Filter Presses

- Automatic Filter Press: The Automatic Filter Press is a fully automated system that uses previous technology to filter solids from liquids. This type of filter press is ideal for industries that require high-quality filtration with minimal downtime.

- Manual Filter Press: The Manual Filter Press is a basic type of filter press that requires manual operation. This type of filter press is ideal for industries with low filtration requirements.

- Plate and Frame Filter Press: The Plate and Frame Filter Press is a versatile type of filter press that can applicate to a wide range of applications. This type of filter press is ideal for industries that require high-quality filtration with flexibility.

- Membrane Filter Press: The Membrane Filter Press uses a membrane to filter solids from liquids. This type of filter press is ideal for industries that require high-quality filtration with high efficiency.

Applications

It has a wide range of applications in various industries, including:

- Chemical industry: Filter presses are popular for separating solids from various chemicals, such as acids, bases, and solvents.

- Food and beverage industry: These equipment presses play an important role in separating solids from liquids, such as juices, wine, and beer.

- Pharmaceutical industry: This type of filter press is popular for separating solids from liquids, such as drugs, vaccines, and blood products.

- Mining industry: Jingjin filter presses applicate for separating solids from mining slurries, such as coal, iron ore, and copper concentrate.

.jpg)

Benefits of Jingjin Filter Presses

This equipment offers several benefits to industries, including:

- Improved filtration efficiency: Jingjin filter presses ensure high-quality filtration, reducing the amount of waste and increasing the quality of the end product.

- Reduced downtime: With their automated and efficient operation, it reduces the need for manual operation, reducing downtime and increasing productivity.

- Low maintenance: Jingjin filter presses require minimal maintenance, reducing operating costs and increasing productivity.

- Reliable and durable: This equipment is made of high-quality materials, ensuring their durability and resistance to wear and tear.

Conclusion

In conclusion, Jingjin filter presses are highly efficient filtration systems that offer a durable and reliable solution for various industries. Understanding the different types of filter presses and their applications can help you choose the right system for your specific needs. Their wide range of applications and benefits make them an ideal choice for industries looking for a reliable and efficient filtration system.