In many industrial processes, the separation of solids and liquids is a critical step. This is where filtration comes in. Filtration is the process of separating solids from liquids or gases using a filter medium. One of the most important components in industrial filtration is the filter cloth.

Leading China Filter Cloth Factory Show Detail Of Filter Cloth?

A filter cloth is a woven fabric that is used to trap and remove solids from liquids or gases. It is typically made from natural or synthetic fibers and is designed to withstand the harsh conditions of industrial filtration. The choice of filter cloth depends on the specific application, with considerations such as chemical compatibility, temperature, and pressure.

What Are The Benefits Of Using A Filter Cloth?

Filtration with filter cloth can remove impurities in liquid or gas, resulting in a higher quality product.

By removing solids from liquids or gases, filter cloths prevent clogging and other problems that can slow down production.

Filtration with filter cloth reduces the amount of waste generated by industrial processes, thereby reducing the environmental footprint.

By preventing clogging and other problems, filter cloths can reduce maintenance costs and downtime.

Filter cloths can be as used in a variety of filtration systems. And also can be as customized for specific applications.

China Filter Cloth Factory How Does A Filter Cloth Work?

A filter cloth works by allowing the liquid or gas to pass through while trapping the solids. The size of the pores in the filter cloth determines what size of particles can be trapped. This is known as the filtration rating or micron rating. The smaller the pores, the finer the filtration.

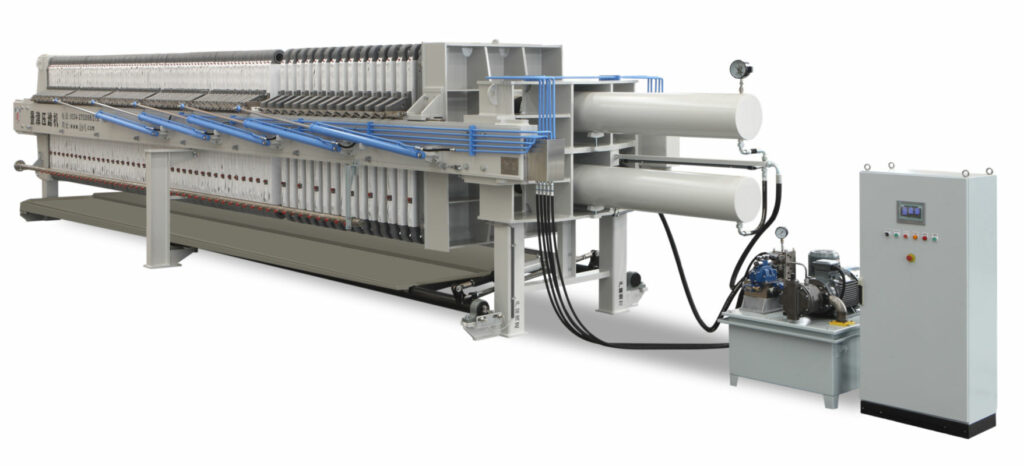

Filter cloths can be as used in a variety of filtration systems. It includes filter presses, rotary drum filters, and vacuum filters. In some cases, multiple layers of filter cloth may be used to achieve the desired filtration rating.

For my Application, How To Choose The Filter Clothes

Determine the required filter cloth micron rating based on the particle size you need to remove.

Make sure the filter cloth material is compatible with the liquid or gas being filtered. This will prevent the filter cloth from deteriorating or breaking.

Consider the temperature and pressure of the filtration system, as these factors affect the performance of the filter cloth.

Consider the cost of the filter cloth, and any costs associated with maintenance and replacement.

Choose filter cloths that are durable enough to withstand the conditions of your filtration system.