In the world of industrial filtration, hydraulic filter press types play a crucial role in separating solids from liquids efficiently. These versatile devices find applications in various industries.

An Overview of Hydraulic Filter Press Types

Hydraulic filter press types are diverse, each designed to address specific filtration challenges. Let’s dive into the main categories of hydraulic filter presses.

Plate and Frame Filter Press

The plate and frame filter press is a classic design featuring a series of filter plates and frames. Solids are trapped within the chambers, while the liquid is collected and discharged. This design offers versatility and is suitable for various industries.

Membrane Filter Press

The membrane filter press includes an additional diaphragm or membrane that applies pressure to the filter cake. This added pressure improves dewatering and can reduce filtration cycle times, making it an excellent choice for slurry applications and materials with high moisture content.

Recessed Plate Filter Press

In the recessed plate filter press, the filter plates have a concave shape, creating a chamber where solids collect. This design is efficient for thick cakes and can handle materials with a high solids content. It’s popular in wastewater treatment and mining.

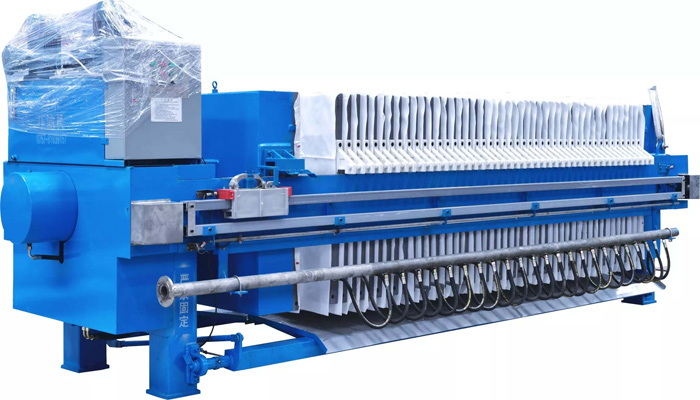

Automatic Filter Press

Automatic filter presses are equipped with automation features such as plate shifting, cake release, and cloth washing. This design is ideal for operations requiring minimal manual intervention and efficient, continuous filtration.

Filter Press Applications

Hydraulic filter press types find applications in various industries. For instance, the plate and frame filter press is popular in winemaking to separate grape solids from juice. In the pharmaceutical industry, membrane filter presses ensure the efficient separation of solids from liquid pharmaceutical products.

Selecting the Right Filter Press Type

Choosing the right hydraulic filter press type depends on your specific filtration needs. Consider factors like the type of material, desired moisture content, and the required automation level. Consulting with filtration experts can help make an informed decision.

Advantages of Hydraulic Filter Press Types

- High Filtration Efficiency: Hydraulic filter presses offer exceptional filtration efficiency, ensuring clean and clear filtrate.

- Reduced Environmental Impact: The ability to achieve high solids content in filter cakes minimizes waste and reduces disposal costs.

- Versatility: Different hydraulic filter press types cater to a wide range of applications, making them a versatile choice for industries.

Conclusion

Hydraulic filter presses come in various types, each tailored to specific filtration requirements. Whether it’s the plate and frame filter press for winemaking or the automatic filter press for continuous operation, understanding these types is essential.

By selecting the right hydraulic filter press for your application, you can optimize filtration, reduce waste, and enhance overall efficiency. Make the right choice to meet your filtration needs effectively.

In summary, hydraulic filter press types offer diverse solutions for industrial filtration, ensuring that solids and liquids are separated efficiently. When selecting the appropriate type, consider the material, and required moisture content. and desired level of automation.

These devices are vital in various industries, helping to achieve clean filtrate and minimize environmental impact. For tailored filtration solutions, explore the world of hydraulic filter press types and consult with filtration experts.