Abstract

The selection of filter media presents a fundamental divergence in methodology and material science when comparing food and beverage applications against general non-food industrial processes. This distinction is rooted in the primary objective of the filtration process itself. For the food industry, the paramount concern is consumer safety, demanding materials that are biologically and chemically inert, compliant with stringent regulatory standards like those from the FDA and EU, and capable of preventing any alteration of the product's sensory characteristics. Consequently, filter media in this sector must be certified as food-grade, demonstrating minimal to no extractables or leachables. In contrast, non-food industrial filtration prioritizes process efficiency, equipment protection, and durability under harsh operating conditions. Material selection is therefore governed by factors such as chemical resistance to aggressive reagents, thermal stability, and mechanical strength against abrasive slurries and high pressures. The analysis of filter media selection for food vs non-food industries reveals that while both seek effective separation, the former is defined by public health mandates and product purity, whereas the latter is driven by economic and operational robustness.

Key Takeaways

- Regulatory compliance (FDA/EU) is non-negotiable for food applications, unlike industrial standards.

- Food-grade media must be inert, preventing taste, odor, or chemical leaching into the product.

- Industrial media prioritize mechanical strength and resistance to harsh chemicals and temperatures.

- The proper filter media selection for food vs non-food industries directly impacts risk management.

- Sanitization capability (CIP/SIP) is a crucial design feature for food filters, not industrial ones.

- Non-food filtration often focuses on maximizing solid cake dryness and process throughput.

- Material construction in food applications minimizes fiber shedding to ensure product purity.

Table of Contents

- Introduction: The Fundamental Divide in Filtration Philosophy

- Difference 1: Regulatory Compliance and Material Certification – The Non-Negotiable Mandate

- Difference 2: Material Composition and Construction – Purity vs. Raw Strength

- Difference 3: Operational Demands – Sanitization vs. Endurance

- Difference 4: Filtration Mechanism and Efficiency – Clarity vs. Throughput

- Difference 5: Cost of Ownership and Risk – Consumer Health vs. Process Downtime

- FAQ: Your Filtration Questions Answered

- Conclusion

- References

Introduction: The Fundamental Divide in Filtration Philosophy

When we think about filtration, the image that often comes to mind is one of simple separation—removing unwanted bits from a liquid. It is a process as ancient as drawing water through woven grass and as modern as purifying biopharmaceuticals. Yet, to approach all filtration tasks with a single mindset would be a profound error. The world of separation science is split by a deep philosophical divide, a line drawn between processes that touch our bodies and those that drive our industries. The filter media selection for food vs non-food industries is not merely a technical choice; it is an ethical and strategic one, where the consequences of a mistake range from a cloudy bottle of juice to a catastrophic industrial failure.

Imagine, for a moment, the difference between a surgeon's scalpel and a woodcarver's chisel. Both are designed to cut, to separate, but their purpose, materials, and handling are worlds apart. The scalpel must be sterile, fashioned from biocompatible steel, and used with the utmost precision to preserve life. The chisel, conversely, must be robust, able to withstand the brute force of a mallet, and sharp enough to shape unyielding material. Its purpose is creation, not preservation. This analogy lies at the heart of our discussion. A filter medium in a dairy processing plant is the surgeon's scalpel; it must be impeccably clean, chemically silent, and designed to protect the consumer from harm. A filter medium in a mining operation is the woodcarver's chisel; it must be tough, resilient, and built to endure a relentless assault of abrasive particles and corrosive chemicals.

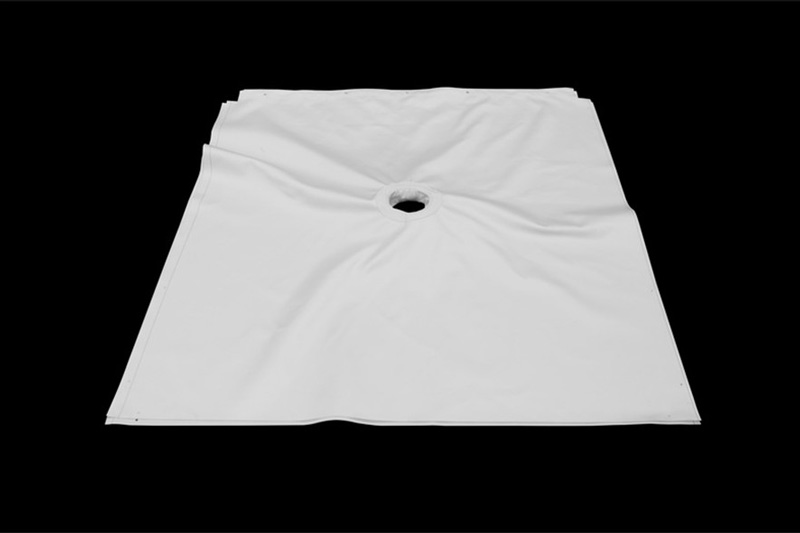

At the core of these systems, whether it's a large-scale industrial filter press or a small cartridge filter, lies the filter medium itself. This is the active barrier, the gatekeeper that determines what passes and what stays. It could be a woven or non-woven high-quality filter cloth, a porous membrane, or a packed bed of granular material. The choices made here ripple outward, affecting the design of the entire system, from the filter plate that supports the medium to the pumps that drive the fluid. The interrogation of these choices reveals that the criteria for success in one domain are often the criteria for failure in the other. In food production, purity is king. In heavy industry, endurance wears the crown. Understanding this fundamental divide is the first and most critical step for any engineer, plant manager, or quality control specialist tasked with designing or operating a filtration process in 2025.

Difference 1: Regulatory Compliance and Material Certification – The Non-Negotiable Mandate

The most rigid and defining difference between selecting a filter for a food product and one for an industrial chemical lies in the web of laws and regulations that govern them. This is not a matter of preference or engineering judgment but of legal mandate. For food applications, the filter is considered an indirect food additive, and its components are subject to intense scrutiny by governmental bodies.

Navigating the FDA and EU Food Contact Maze

In the United States, the Food and Drug Administration (FDA) is the principal authority. Materials intended for contact with food are regulated under Title 21 of the Code of Federal Regulations (CFR). A filter medium, including the filter cloth and the filter plate it rests on, must be constructed from polymers and additives that are on the FDA's list of approved substances. This means the manufacturer must be able to provide documentation that unequivocally proves every single component of the filter—from the polymer resin to the thread used for stitching—complies with these regulations.

The European Union has a similarly stringent, albeit structurally different, framework. Regulation (EC) No 1935/2004 provides the general principles for materials and articles intended to come into contact with food. A core tenet of this regulation is that materials shall not transfer their constituents to food in quantities that could endanger human health, bring about an unacceptable change in the composition of the food, or cause a deterioration in its organoleptic properties (taste and smell). Specific measures for plastics, for instance, are detailed in Regulation (EU) No 10/2011, which includes a "Union List" of authorized substances. A filter manufacturer selling into the European market must provide a Declaration of Compliance, a formal statement warranting that their product meets these legal requirements. This often involves rigorous migration testing, where the filter is exposed to food simulants (like ethanol to mimic alcoholic beverages or acetic acid to mimic acidic foods) to measure what, if anything, leaches out.

The Contrast with Industrial Standards

The regulatory landscape for non-food industries is starkly different. Here, the focus shifts from consumer health to occupational safety, environmental protection, and process integrity. Governing bodies like the Occupational Safety and Health Administration (OSHA) in the US care about worker exposure to hazardous chemicals. The Environmental Protection Agency (EPA) regulates the discharge of filtrate, ensuring it doesn't pollute waterways.

The standards that apply to the filter media itself are typically performance-based, developed by organizations like the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). These standards define test methods for things like tensile strength, air permeability, or chemical resistance. An engineer selecting a filter for a chemical plant will consult these standards to ensure the medium can withstand the process, not to ensure it's safe to eat off of. The certification is one of performance and durability, not biocompatibility. There is no concept of a "food-grade" declaration because there is no food.

Material Inertness and Leachables

This regulatory disparity is born from a genuine chemical concern: the issue of extractables and leachables. An "extractable" is a compound that can be pulled out of the filter material under exaggerated conditions in a laboratory (e.g., using aggressive solvents, high temperatures). A "leachable" is a compound that actually migrates from the filter into the product under normal process conditions.

In the food and beverage industry, the prevention of leachables is a primary design goal (Pall Corporation, n.d.). Imagine filtering a delicate white wine. If the filter cloth leaches even trace amounts of a chemical, it could impart a "plastic" taste, ruining the entire batch. Worse, it could introduce a substance that is harmful to human health. For this reason, food-grade filters undergo extensive testing to ensure they are chemically silent.

Now, consider filtering an industrial slurry in a mining operation. The liquid phase might be a caustic solution used for leaching minerals. The primary concern here is that the filter cloth does not dissolve or degrade upon contact with the solution. Whether the cloth leaches a minute, non-reactive compound into the wastewater is of little to no consequence, as long as it does not compromise the structural integrity of the filter or violate environmental discharge limits. The focus is on the filter's survival, not its subtlety.

This table crystallizes the opposing priorities driven by regulation.

| Feature | Food & Beverage Industry | General Industrial (Non-Food) |

|---|---|---|

| Primary Goal | Consumer safety, product purity, and sensory integrity. | Process efficiency, equipment protection, and environmental compliance. |

| Governing Bodies | FDA (USA), EFSA/EU (Europe), and national equivalents. | ISO, ASTM, EPA, OSHA, and industry-specific bodies. |

| Material Requirements | Must be on approved "food contact" lists (e.g., FDA CFR 21, EU 10/2011). | Based on chemical compatibility, temperature, and pressure tolerance. |

| Certification | Mandatory food-grade certification and traceability of all components. | Performance certifications (e.g., beta ratio, tensile strength, permeability). |

| Leachables Testing | Mandatory and extensive to prevent product contamination and health risks. | Tested primarily for process compatibility, not human consumption. |

Difference 2: Material Composition and Construction – Purity vs. Raw Strength

The regulatory frameworks discussed previously directly dictate the palette of materials available to filter designers. The choice of polymer, the way the fibers are woven, and the final finish of the fabric are all consequences of the application's core purpose. This results in two distinct arsenals of materials, one selected for its purity and the other for its power.

The Palette of Food-Grade Materials

For food and beverage filtration, the list of acceptable materials is relatively narrow and well-defined. The workhorses of the industry are thermoplastics known for their chemical inertness and cleanability.

-

Polypropylene (PP): This is arguably the most common material for both filter cloth and the structural components of filter plates in food applications. It has broad chemical compatibility with the acids, bases, alcohols, and oils typically found in foodstuffs. It is hydrophobic, which can be advantageous, and has a reasonable temperature limit (typically around 90°C or 194°F). It's economical and can be manufactured to high purity standards.

-

Polyester (PET): Polyester offers superior mechanical strength and better resistance to abrasion than polypropylene. It also has a higher temperature tolerance. It's often chosen for applications involving more abrasive food slurries, like processing starches or sugars, where the longevity of the filter cloth is a concern.

-

Nylon (Polyamide): Nylon is known for its excellent strength and elasticity, making it very durable. Its key advantage is its performance in alkaline conditions, where materials like polyester might struggle. It is commonly found in applications like edible oil filtration.

Beyond these, natural fibers like cotton are sometimes used for their unique filtration properties, especially in processes like maple syrup filtration, but they have limitations in terms of cleanability and chemical resistance. What unites all these materials is that they are produced in specific "food-grade" variants, often with a higher level of quality control to eliminate impurities, catalysts, and additives that might be present in their industrial-grade counterparts.

The Arsenal of Industrial Materials

When you step outside the food industry, the constraints of biocompatibility vanish, and the material options expand dramatically. The selection becomes a pure calculation of performance against cost. The goal is to find a material that can survive the most aggressive chemical, thermal, and physical challenges imaginable.

-

High-Performance Polymers: While polypropylene and polyester are also used in industry, they are often joined by more exotic and robust polymers. Polyvinylidene fluoride (PVDF) offers a fantastic combination of chemical resistance, high strength, and UV stability. Polytetrafluoroethylene (PTFE), the same family as Teflon, is nearly chemically inert and can handle extremely high temperatures (up to 260°C or 500°F), making it ideal for filtering aggressive solvents or acids.

-

Metallic Media: For extreme temperature and pressure applications, woven metal meshes or sintered metal powders are used. Stainless steel (typically 316L grade) is common, but for highly corrosive environments like those involving chlorides or strong acids, more exotic alloys like Monel, Hastelloy, or even titanium are employed. These materials would be prohibitively expensive and often unnecessary for a food application.

-

Fiberglass and Other Specialized Fabrics: In high-temperature gas filtration (e.g., in cement kilns or power plants), fiberglass fabrics, often coated with PTFE, are used to capture dust at temperatures that would instantly melt standard polymers.

Weave, Pore Size, and Surface Finish

The material itself is only half the story. The way it is constructed plays an equally significant role. The design of a filter cloth is a complex interplay of fiber diameter, weave pattern (e.g., plain, twill, satin), and finishing processes.

In food applications, a critical concern is preventing the filter medium from becoming a breeding ground for bacteria. Biofilms can be notoriously difficult to remove. For this reason, food-grade filter cloths often feature a very smooth, non-porous surface. This is achieved through processes like calendering, where the fabric is passed through heated rollers to flatten the fibers and seal the surface. This creates a cake-release surface that is easier to clean and less likely to harbor microorganisms. Furthermore, the construction must minimize fiber shedding. No one wants to find plastic fibers in their yogurt. The weave is often very tight and stable to prevent fibers from breaking off and entering the filtrate.

In heavy industrial applications, the priorities are different. Here, filtration efficiency and cake dewatering are often paramount. A manufacturer might choose a "napped" finish for a filter cloth used in a filter press. This means the surface fibers are raised to create a fuzzy texture. This napped surface is excellent for capturing very fine particles at the beginning of a filtration cycle, quickly building a pre-coat that improves overall efficiency. However, this same surface would be a hygienic nightmare in a food plant, as it is incredibly difficult to clean thoroughly. The weave might be designed for maximum water flow (permeability) rather than particle retention finesse, relying on the filter cake itself to do the bulk of the filtration work. The choice of customized filter cloth solutions becomes a strategic decision based on these competing demands.

This table provides a comparative glance at the material properties that guide selection.

| Property | Food-Grade Media (e.g., Polypropylene) | Industrial-Grade Media (e.g., PTFE, Stainless Steel) |

|---|---|---|

| Primary Material Driver | Inertness, purity, regulatory approval. | Chemical, thermal, and mechanical resistance. |

| Typical Temperature Range | Moderate (e.g., up to 90°C / 194°F). | Can be extremely wide (e.g., -100°C to >260°C / -148°F to >500°F). |

| Surface Finish | Smooth, calendered, non-porous for cleanability. | Often napped or textured to enhance particle capture. |

| Fiber Shedding | Must be minimal to zero to prevent product contamination. | Tolerable to a degree, depending on the downstream process. |

| Cost | Moderate; certification and quality control add to the price. | Can range from low to extremely high for specialized alloys. |

Difference 3: Operational Demands – Sanitization vs. Endurance

How a filter is used and maintained day-to-day reveals another profound chasm between the food and non-food worlds. A food-grade filter lives a life of cyclical stress: process, clean, sterilize, repeat. An industrial filter lives a life of constant battle: endure, perform, and resist until failure. These operational realities heavily influence the filter media selection.

The Clean-in-Place (CIP) and Sterilize-in-Place (SIP) Imperative

In any food, beverage, or pharmaceutical plant, hygiene is paramount to prevent microbial contamination. It is simply not feasible to disassemble a large filter press or piping system for cleaning after every batch. This is where Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems become essential.

A typical CIP cycle involves flushing the entire system, including the filter media, with a sequence of chemicals at elevated temperatures. This might include:

- A pre-rinse with water.

- A hot caustic wash (e.g., sodium hydroxide) to break down fats and proteins.

- An intermediate rinse.

- A hot acid wash (e.g., nitric or phosphoric acid) to remove mineral scale.

- A final rinse.

Following cleaning, a sterilization or sanitization step (SIP) is often required. This can involve circulating very hot water (e.g., >85°C), steam (e.g., >121°C), or chemical sanitizers like peracetic acid or chlorine dioxide.

What does this mean for the filter media? It means the filter cloth and filter plate must be able to withstand these repeated, aggressive chemical and thermal cycles without degrading. A material that is perfectly compatible with the food product itself might be rapidly destroyed by the cleaning agents. For example, polyester (PET) has poor resistance to strong caustics and hot water/steam over time (hydrolysis), making it a less suitable choice than polypropylene or PVDF in applications requiring aggressive CIP/SIP regimes. The filter media must be chosen not just for the filtration task, but for the cleaning task that will follow, often hundreds of times over its lifespan.

Abrasion, Pressure, and Chemical Warfare in Industry

The life of an industrial filter cloth is typically far more brutal, but in a different way. The concept of cleaning for hygiene is often absent. The filter is "cleaned" only in the sense that the collected solid cake is removed. The challenges it faces are not cyclical cleaning chemicals but the constant, unyielding nature of the process stream itself.

Consider a filter press dewatering tailings from a copper mine. The slurry is not just water and solids; it is a highly abrasive mixture of fine rock particles, sand, and clay. The filter cloth is subjected to intense physical wear every single cycle as the slurry is pumped in under high pressure and the cake is discharged. The material must possess exceptional abrasion resistance to avoid being simply worn away.

In a chemical manufacturing plant, a filter press might be used to separate a catalyst from a solvent. The solvent could be a highly aggressive organic chemical like toluene or acetone, and the process might run at an elevated temperature to improve efficiency. The filter cloth material (like PTFE) must be selected for its ability to remain chemically inert and mechanically stable in this environment, 24 hours a day, 7 days a week. The pressure within the filter press chambers can be immense, exceeding 15-20 bar (220-290 psi) in modern high-performance units. The cloth must have the tensile strength to withstand these forces without stretching, tearing, or "blinding" (where particles become permanently lodged in the fabric's pores).

Lifetime and Replacement Cycles

These different operational demands lead to different philosophies on filter media lifetime and replacement. In a food plant, a filter cloth might be replaced on a pre-determined schedule, regardless of its physical appearance. It might be replaced after a set number of cleaning cycles because the manufacturer knows that the material's integrity could be compromised, even if it's not visible. The risk of a microscopic failure leading to bacterial contamination is too high to justify running the filter to the point of mechanical failure. The lifetime is dictated by a hygiene-based risk assessment.

In an industrial setting, the opposite is often true. The filter cloth is a consumable, and the goal is to maximize its operational life to minimize cost and downtime. It will be used until its performance drops below an acceptable threshold. This could be when the filtration cycle times become too long (due to blinding), the resulting filter cake is too wet, or the filtrate is no longer clear enough. In some cases, it is used until it physically fails—a tear appears, causing a "blowout" that contaminates the filtrate with solids. The lifetime is dictated by economic and performance metrics.

Difference 4: Filtration Mechanism and Efficiency – Clarity vs. Throughput

While all filtration involves separation, the specific goal of that separation can be vastly different. This influences not only the choice of filter media but also the entire operational strategy. In food, the goal is often to perfect the liquid. In industry, the goal is often to get rid of the liquid.

Achieving "Brilliant" Clarity in Beverages

Think about a bottle of commercial apple juice, a pilsner beer, or a sauvignon blanc wine. They are typically crystal clear, or "brilliantly polished." This clarity is not just for aesthetics; it is also a mark of stability. The particles removed—yeast cells, protein-tannin hazes, microscopic fruit fragments—can cause the product to become cloudy, change flavor, or spoil over time if left in the final package.

To achieve this, food and beverage producers use filtration that targets very specific particle sizes. This is where the concept of a filter's "rating" becomes critical. Filters can have a nominal rating (e.g., removes most particles larger than 5 microns) or an absolute rating (e.g., removes 99.9% of particles larger than 1 micron). For microbial stabilization, such as removing yeast and spoilage bacteria from wine, filters with an absolute rating of less than 1 micron are required (Matter, 2024).

The mechanism here is often a combination of surface filtration (particles caught on the surface) and depth filtration (particles caught within the tortuous path of the filter matrix). The quality of the filtrate—the liquid that passes through—is the single most important measure of success. High throughput is desirable, but not at the expense of clarity and purity.

Dewatering and Solid Recovery in Industrial Processes

Now, shift your perspective to a municipal wastewater treatment plant. A filter press is used to dewater digested sludge. The goal here is not to produce pristine, drinkable water (though that is handled elsewhere in the plant). The primary objective is to take a slurry that is 97% water and turn it into a solid "cake" that is only 60-70% water.

Why? Because the cost of disposing of this sludge is often based on weight or volume. By removing as much water as possible, the plant dramatically reduces its disposal costs. In this context, the key performance indicators (KPIs) are cake dryness and throughput. How many tons of dry solids can the filter press process per hour? The clarity of the filtrate, while not irrelevant (it's typically recycled back to the head of the plant), is secondary to the dewatering performance.

Similarly, in the mining industry, a filter press is used to recover valuable solids from a slurry or to dewater tailings for "dry stacking," an environmentally safer method of storage. The value is in the cake. The filter cloth is selected for its ability to release this cake cleanly and to allow water to pass through as quickly as possible. The mechanism is primarily surface filtration, with the goal of building a thick, uniform cake that then acts as its own filter medium.

The Role of Filter Aids

To bridge the gap between efficiency and fine particle capture, both industries often employ filter aids. These are inert, porous powders that are used to form a preliminary filtration layer on top of the filter cloth.

- Diatomaceous Earth (DE): A powder made from the fossilized remains of diatoms.

- Perlite: A processed volcanic glass.

- Cellulose: Processed wood pulp.

In the food industry, a slurry of DE might be circulated through the filter to build a "pre-coat" on the cloth before the actual product is introduced. This pre-coat does the fine filtration, protecting the cloth from blinding and achieving brilliant clarity. Crucially, the filter aid itself must be food-grade.

In industrial applications, filter aids are also used to improve dewatering and prevent cloth blinding, especially with slimy or gelatinous solids. However, the choice of aid is much broader and driven purely by cost and effectiveness. Lower-grade DE, fly ash, or other inexpensive materials can be used, as there is no concern about them being safe for consumption. The use of a filter aid allows for the use of a more robust, open-mesh filter cloth, which has a longer life and higher flow rate, while the aid provides the necessary filtration finesse.

Difference 5: Cost of Ownership and Risk – Consumer Health vs. Process Downtime

Ultimately, the filter media selection for food vs non-food industries is a decision rooted in risk management and economics. The definition of "cost" and "risk" in these two spheres, however, could not be more different. The final choice reflects a calculation of what is truly at stake.

The True Cost of a Food-Grade Filter

When a food company purchases a filter, the price on the invoice is just the beginning of its total cost of ownership (TCO). The true cost encompasses a much wider range of factors:

- Validation and Documentation: The cost of the filter includes the extensive paperwork proving its compliance with FDA or EU regulations. This is not optional. The company must invest time and resources to validate that the filter performs as expected and does not harm the product.

- Rigorous Cleaning Regimes: The cost of the water, energy, and chemicals used in daily CIP and SIP cycles is substantial. The labor required to monitor these cycles and test for cleaning efficacy also adds up.

- Increased Replacement Frequency: As discussed, food-grade filters are often replaced on a preventative schedule to mitigate hygiene risks, not just when they fail. This higher turnover rate is a direct operational cost.

- The Cost of Failure: This is the most significant factor. What is the cost of a filtration failure? It is not a broken part; it is a public health crisis. A batch of contaminated product could lead to a widespread product recall, costing millions of dollars in logistics, lost inventory, and fines. The damage to the brand's reputation can be even more costly and long-lasting, potentially destroying consumer trust built over decades. When viewed through this lens, the higher price of a certified, high-purity filter medium is not an expense but a critical insurance policy.

Industrial Cost-Benefit Analysis

In a non-food industrial setting, the economic calculation is more direct and tangible. The total cost of ownership is weighed against the immediate economic impact on the process.

- Media Lifespan and Throughput: The primary drivers are performance-based. The engineer will ask: How long will this filter cloth last under our abrasive conditions? How many gallons per minute can it process? How dry will the resulting cake be? The choice is often the one that provides the lowest cost per ton of processed material.

- Downtime Costs: The cost of stopping a continuous industrial process can be enormous. If a filter press has to be taken offline for an unscheduled filter cloth change, the entire upstream and downstream production line might have to halt. This lost production often dwarfs the cost of the filter media itself. Therefore, durability and reliability are prized above all else. A slightly more expensive but longer-lasting cloth is almost always the better economic choice.

- The Cost of Failure: The risk here is not a public health scandal but an economic or environmental one. A torn filter cloth could lead to solids contaminating the filtrate, potentially damaging downstream equipment like pumps or heat exchangers. It could result in an environmental discharge violation, leading to fines. It could mean that a valuable product (the solids) is lost to the waste stream. These are serious financial risks, but they are of a fundamentally different nature than the risk of making consumers sick.

A Case Study in Contrast: Dairy Filtration vs. Mining Tailings

Let's make this concrete.

Scenario 1: Cold Sterilization of Milk. A dairy is filtering raw milk before pasteurization to remove bacteria and spores (a process called microfiltration). The filter medium is a sophisticated polymer membrane with an absolute pore size of around 1.4 microns. The material must be certified to FDA standards, capable of withstanding daily CIP with caustic and acid, and weekly SIP with 125°C steam. The entire system, including the filter plate housing, is made of polished stainless steel to eliminate crevices where bacteria could hide. The filter cartridges are expensive and are replaced every few months, long before they show signs of physical wear. The risk of failure is a batch of milk contaminated with Listeria, leading to a recall, regulatory action, and a public relations disaster. The high cost is justified by the near-elimination of this risk.

Scenario 2: Dewatering Iron Ore Tailings. A mining company needs to dewater the waste slurry from its concentrator plant. They use a massive filter press with dozens of chambers. The filter cloth is a heavy-duty, woven polypropylene fabric with a special twill weave designed for high strength and abrasion resistance. The surface is napped to improve capture. It is not "cleaned" in a hygienic sense; it is simply scraped or washed to remove the cake. The cloth is run 24/7 under high pressure until it either tears or the filtration cycles become unacceptably long. The risk of failure is that a tear causes the press to shut down, backing up the entire concentrator plant at a cost of thousands of dollars per hour in lost production. The choice of filter cloth is based on a brutal calculus of durability versus cost, seeking the lowest possible operating cost per ton of tailings processed.

These two scenarios, both employing filtration, exist in separate universes of risk, cost, and purpose. The intelligent selection of filter media requires not just understanding the technical specifications, but deeply appreciating which universe you are operating in.

FAQ: Your Filtration Questions Answered

Can I use an industrial filter for a food application if I clean it really well? Categorically, no. The fundamental issue is not cleanliness but material composition and certification. Industrial-grade filter media are not made from FDA or EU-compliant materials. They may contain additives, catalysts, or processing aids that are not safe for human consumption and can leach into your product. Furthermore, they lack the required traceability and formal Declaration of Compliance, which would put your operation in legal violation of food safety laws.

What is the most common filter media material for a food industry filter press? Polypropylene (PP) is the most widely used material for filter cloths in food-grade filter presses. It offers a great balance of chemical compatibility with most food products and cleaning agents, good mechanical properties, and is economically viable. For the filter plates themselves, food-grade polypropylene is also the industry standard for the same reasons.

How do I know if a filter cloth is truly food-grade? You must request and receive formal documentation from the supplier. This is not a verbal assurance. For products sold in the US, this would be a statement of compliance with the relevant FDA 21 CFR sections. For Europe, it would be a Declaration of Compliance citing Regulation (EC) 1935/2004 and relevant specific measures like (EU) 10/2011 for plastics. The documentation should be specific to the product you are purchasing.

What primarily affects the lifespan of a filter cloth in a non-food application? The four main factors are abrasion, chemical attack, pressure, and temperature. Abrasive slurries physically wear down the fibers. Aggressive chemicals can weaken or dissolve the polymer. High pressures during filtration can stretch and deform the weave, a phenomenon known as "yarn creep." High temperatures can accelerate chemical degradation and cause the material to lose its tensile strength.

Is membrane filtration replacing traditional filter cloth in all applications? No, they serve different, though sometimes overlapping, purposes. Traditional filter cloths used in a filter press are workhorses for bulk solid-liquid separation and dewatering. They are designed to handle high solids content and produce a dry filter cake. Membrane filtration, such as microfiltration or ultrafiltration, is typically used for clarification and purification of liquids with lower solids content, targeting much finer particles like bacteria or macromolecules (Peter, 2023). Often, they are used sequentially; a filter press might perform the initial bulk separation, and a membrane system might "polish" the resulting liquid.

How does the filter plate material relate to the filter media selection? The filter plate and the filter media form a system and must be compatible. The plate material must have the same or better chemical and thermal resistance as the cloth. It makes no sense to use a high-temperature PTFE filter cloth on a standard polypropylene plate that will soften and deform at those temperatures. In food applications, both the plate and the cloth must be made from food-grade materials. The plate's design also affects the cloth's performance, providing the necessary support against high filtration pressures.

Conclusion

The journey through the world of filter media reveals that the path to a successful separation process is not singular but forked. On one side lies the domain of food and beverage, a realm governed by the solemn responsibility to protect public health. Here, the selection process is a meticulous exercise in regulatory compliance, material purity, and hygienic design. The filter is a guardian of the product's integrity and the consumer's safety. Every choice is weighed against the catastrophic risk of contamination, making caution and certification the guiding principles.

On the other side stretches the vast landscape of industrial applications, where the laws of physics and economics reign supreme. Here, the filter is a tool of production, a robust workhorse designed for endurance in the face of chemical aggression, abrasive solids, and extreme temperatures. The selection is a pragmatic calculation of strength, efficiency, and operational cost. The risk is not one of public health but of process downtime and economic loss.

To confuse these two worlds is to invite failure. Using an industrial filter in a food plant is a dangerous breach of safety and law. Using a delicate, food-grade filter in an abrasive industrial slurry is an act of economic folly. Therefore, the prudent engineer, manager, or operator must first ask not "what does this filter do?" but "what must this filter protect?" Is it the person who will consume the product, or the process that creates it? Answering this question with clarity and conviction is the foundation upon which all effective and responsible filter media selection is built.

References

Matter, C. G. (2024). Membrane filtration (micro and ultrafiltration) in water purification. In The handbook of environmental chemistry. Springer. https://doi.org/10.1007/978-3-319-78000-9_3

Pall Corporation. (n.d.). BACK TO BASICS: Understanding particle filtration in liquids in food and beverage industry applications. Pall Corporation.

Peter, M. (2023). Membrane filtration. In Oxford research encyclopedia of global public health. Oxford University Press.

Razali, M. C., Wahab, N. A., Sunar, N., & Shamsudin, N. H. (2023). Existing filtration treatment on drinking water process and concerns issues. Membranes, 13(3), 285. https://doi.org/10.3390/membranes13030285

Saha, U. K. (2025). Household water treatment: Mechanical filtration methods and devices (Publication No. B1523). University of Georgia Extension.

Sutherland, K. (2008). Filters and filtration handbook (5th ed.). Elsevier.

U.S. Food and Drug Administration. (2024). CFR – Code of Federal Regulations Title 21.

European Commission. (2004). Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food. Official Journal of the European Union.