Abstract

The process of separating solids from liquids via cake filtration is fundamental across numerous industries, yet the discharge of the formed filter cake frequently presents a significant operational bottleneck. This analysis examines the transition from manual to automated filter cake discharge as a pivotal step toward enhancing plant efficiency and reducing operational costs. It provides a comprehensive exploration of five principal automation technologies available in 2025: automated plate shifters, vibrating devices, filter cloth movement systems, air-assisted blowback, and integrated cake scrapers. The study evaluates each system's mechanical principles, operational suitability for different cake properties, and economic implications. By contextualizing these technologies within industrial applications, such as mining and wastewater treatment, the discourse illuminates the complex decision-making matrix plant operators face. The objective is to furnish a detailed, structured guide that facilitates an informed selection of an automation strategy, considering slurry characteristics, return on investment, and integration with existing control infrastructure, thereby transforming a labor-intensive task into a streamlined, autonomous process.

Key Takeaways

- Automating filter cake discharge dramatically reduces manual labor and associated safety risks.

- Evaluate your cake's stickiness and moisture to select the most effective discharge system.

- Automated plate shifters offer a reliable, robust solution for many standard applications.

- Vibration and air blowback systems can significantly shorten dewatering cycle times.

- Integrated scrapers and breakers are ideal for handling particularly stubborn or large cakes.

- A thorough ROI analysis is necessary before investing in a filtration automation system.

- Proper automation enhances overall plant efficiency and lowers long-term operational costs.

Table of Contents

- The Foundational Logic of Cake Filtration

- System 1: Automated Plate Shifting Mechanisms

- System 2: Vibrating and Shaking Devices

- System 3: Automated Filter Cloth Movement Systems

- System 4: Air-Assisted and Blowback Systems

- System 5: Integrated Cake Scrapers and Breakers

- Selecting the Optimal Automation Strategy for Your Operation

- Frequently Asked Questions (FAQ)

- Conclusion

- References

The Foundational Logic of Cake Filtration

Before we can appreciate the elegance and efficiency of automating filter cake discharge, we must first build a solid understanding of the process that precedes it. Imagine making coffee with a paper filter. You pour a mixture of hot water and ground coffee—a slurry—into the filter. The liquid coffee passes through, but the solid coffee grounds are left behind, forming a damp layer. At its core, industrial cake filtration operates on this very same principle, albeit on a much grander and more sophisticated scale (Mazzeo, 2024). It is a mechanical solid-liquid separation process where the solids accumulate on a filter medium to form what is known as a filter cake.

Demystifying the Filter Cake: From Slurry to Solid

In an industrial setting, such as in a filter press, the process begins by pumping a slurry under pressure into a series of chambers. These chambers are formed by filter plates, each lined with a specialized filter cloth. The filter cloth acts as the separation barrier. The liquid phase of the slurry, or the filtrate, is forced through the pores of the cloth, leaving the solid particles behind. As filtration continues, these particles build upon one another on the surface of the cloth. This accumulation is the filter cake.

Initially, some of the finer particles might pass through the cloth or become embedded within its weave. However, very quickly, the accumulating solids form a preliminary layer that acts as its own filter medium, often capturing much finer particles than the cloth alone could. This phenomenon is why it's called cake-forming filtration; the cake itself becomes an active and essential part of the separation process (Anlauf, 2025). The structure of this cake—its porosity, compressibility, and resistance to flow—is determined by the nature of the solid particles, the pressure applied, and the chemistry of the slurry. The goal of the filtration cycle is to produce a cake that is as dry as possible and a filtrate that is as clear as possible. This cycle is a cornerstone of operations in industries ranging from mining and metallurgy to chemical production and municipal wastewater treatment (Diemme Filtration, 2024).

The Critical Juncture: Why Cake Discharge Matters

After the filtration cycle is complete, the press is opened, and the chambers are separated. What remains is a series of solid, dewatered filter cakes held between the filter plates. Now comes the most physically demanding and often time-consuming part of the entire operation: discharging these cakes. The cakes must be removed from the filter cloths to prepare the press for the next cycle. The efficiency of this single step has a disproportionately large impact on the overall productivity of the filtration plant.

The properties of the cake dictate the difficulty of its discharge. Some cakes are dry, brittle, and simply fall away from the cloth under their own weight once the plates are separated. These are the ideal scenario. More often, however, cakes can be sticky, moist, pliable, or thin. They adhere tenaciously to the filter cloth, refusing to release without intervention. This adhesion is a result of complex surface forces, including van der Waals forces, capillary action from residual moisture, and the physical interlocking of particles with the cloth's fibers. The challenge of overcoming these forces is the central problem that automating filter cake discharge aims to solve.

The Human and Economic Cost of Manual Discharge

In a non-automated setup, the task of cake discharge falls to human operators. They must manually separate the plates and then use tools, typically long plastic or wooden spatulas, to scrape, pry, and coax the cake from each filter cloth, one chamber at a time. This is grueling, repetitive, and often unpleasant work, performed in a damp environment.

Consider the implications. First, there is the direct labor cost. A significant portion of an operator's time is spent just on this manual task. Second, there is the issue of cycle time. The time it takes to manually clean a large filter press can be substantial, representing a period of non-productive downtime for the equipment. If cake discharge takes 45 minutes on a 3-hour cycle, it accounts for 25% of the total cycle time. Reducing this time directly increases the number of cycles that can be run per day, thereby increasing the plant's total throughput and efficiency.

Third, there are significant safety and ergonomic concerns. Repetitive motion with scrapers can lead to musculoskeletal injuries. Operators may be exposed to the chemical or biological nature of the cake material. There is also the risk of injury from the heavy, moving parts of the filter press itself. Automating filter cake discharge is therefore not merely a matter of economic optimization; it is a profound step toward creating a safer and more humane working environment. It shifts the burden from the operator to a machine, transforming the filtration process from a batch operation punctuated by intense manual labor into a much smoother, more continuous, and highly efficient system.

System 1: Automated Plate Shifting Mechanisms

The first and perhaps most foundational layer of filter press automation is the automated plate shifter. Before any cake can be discharged, the packed filter plates that form the press chambers must be separated. In a manual operation, this is done by hand, with an operator pulling each heavy plate, one by one. An automated plate shifter mechanizes this core function, providing the first step away from purely manual labor and setting the stage for more advanced discharge systems.

The Mechanical Principle: How Plate Shifters Work

Imagine a line of dominoes standing on end. To separate them, you could move each one individually. A plate shifter works like a mechanical hand that performs this action automatically. The system typically consists of a shifting mechanism that travels along the side rails of the filter press. This mechanism latches onto a handle or lug on each filter plate, pulls it open a set distance, disengages, returns to the starting position, and then repeats the process for the next plate.

The most common designs use a carriage that moves along a track, driven by a hydraulic motor or an electric motor coupled with a chain or belt. Sensors detect the position of the plates and the carriage, ensuring that each plate is gripped and moved in the correct sequence. The control system can be programmed for different speeds and can include safety features to stop the process if a plate becomes jammed. This sequential, reliable action ensures that the press is opened in a controlled manner, providing the necessary space for the filter cakes to fall. For many operations, simply automating this plate-opening step is a massive improvement, as it allows a single operator to supervise the process rather than physically performing it.

Varieties of Shifters: From Simple Chains to Complex Robotics

Plate shifting technology has evolved, offering a range of options to suit different operational needs and budgets.

- Simple Chain-Driven Systems: These are the workhorses of the industry. They use a continuous chain loop with one or more "dogs" or pawls that engage the plate handles. As the chain moves, it pulls the plates open in sequence. They are mechanically simple, robust, and relatively easy to maintain, making them a popular choice for rugged environments like those in mining or aggregate processing.

- Hydraulic Carriage Systems: These shifters use a hydraulic cylinder to power a carriage that grips, pulls, and releases each plate. They offer smooth, powerful, and highly controllable motion. The speed and force can be easily adjusted, which is beneficial when dealing with older presses or plates that may not move as freely.

- Electric Servo-Driven Systems: Representing a more advanced approach, these systems use electric servo motors. They provide exceptionally precise control over speed, acceleration, and position. This precision can reduce mechanical stress on the plates and frame of the press. They are also generally quieter and cleaner than hydraulic systems, as there is no risk of hydraulic fluid leaks, making them suitable for food-grade or pharmaceutical applications.

- Robotic Shifters: At the highest end of the spectrum, some systems employ a dedicated robot arm mounted alongside the press. The robot can be programmed to perform not only the plate shifting but also more complex tasks, such as triggering a vibration sequence or even assisting with cloth washing. This offers the ultimate in flexibility but comes with a higher initial investment and requires more specialized maintenance.

The choice among these systems depends on a careful evaluation of the specific application, weighing the need for speed, precision, and flexibility against the realities of budget and the existing plant environment.

Assessing Suitability: When is a Plate Shifter the Right Choice?

An automated plate shifter is almost always a worthwhile investment for any medium to large-sized filter press. It is the gateway to automating filter cake discharge. However, it's important to recognize what it does and does not do. A plate shifter automates the opening of the press, but it does not, by itself, guarantee the discharge of the cake.

A plate shifter is the ideal solution under two primary conditions:

- When the filter cake is non-sticky and self-releasing: If your process yields a cake that is dry, brittle, and falls away from the cloth easily under its own weight, an automated plate shifter is all you need. The shifter opens the plates, the cakes fall onto a conveyor or into a hopper below, and the press is ready for the next cycle. The automation is simple, effective, and reliable.

- As a foundational component for other automation: If your cake is sticky, a plate shifter is the necessary first step upon which other discharge aids are built. You cannot install a vibrator, an air blowback system, or a scraper without first having a reliable way to open the plates automatically. The shifter works in concert with these other systems, opening a chamber and then pausing while the secondary system does its work to dislodge the cake.

In essence, think of the plate shifter as the conductor of an orchestra. It doesn't play an instrument itself, but it controls the timing and sequence, allowing each section—the vibrators, the air jets, the scrapers—to perform its function at the correct moment. Without this conductor, there is only noise and inefficiency. With it, you have a coordinated, automated process.

Case Study: Mining Operations in South America

Consider a large copper concentrate dewatering facility in the Andes. They operate several large filter presses, each with over 150 plates. Previously, the discharge cycle was a major bottleneck. It required two operators per press to manually pry open the heavy plates and scrape off the dense, metallic cake. The process took over an hour, exposing operators to physical strain and limiting the plant to only four cycles per press per day.

After retrofitting the presses with robust, hydraulically-driven automatic plate shifters, the plate opening sequence was reduced to just 15 minutes. While the cake still required some assistance to discharge fully, the automation of the heaviest part of the labor allowed a single operator to supervise two presses. This operator could now focus on using a targeted air lance or water spray on the few stubborn spots, rather than fighting every single plate. The immediate result was a reduction in direct labor costs and a significant improvement in operator safety and morale. More importantly, the shortened cycle time allowed the plant to consistently achieve five cycles per day, a 25% increase in throughput, without investing in new filter presses. This project demonstrated that even this first level of automation can yield a substantial return on investment.

System 2: Vibrating and Shaking Devices

Once the automated plate shifter has done its job of separating the filter plates, the next challenge arises: the cake itself. What if it doesn't simply fall away? For many industrial slurries, the resulting filter cake possesses an adhesive quality, clinging to the filter cloth with surprising tenacity. This is where the principle of induced vibration comes into play. By imparting mechanical energy into the plate or cloth, we can overcome the forces of adhesion and persuade the cake to release.

Harnessing Resonance: The Physics of Cake Loosening

At a microscopic level, a sticky filter cake is held to the cloth by a combination of forces. Moisture in the cake creates surface tension and capillary action, effectively "gluing" the solids to the fabric. The particles themselves may also have an electrostatic charge or a physical shape that causes them to interlock with the woven fibers of the cloth.

A vibrating device works by rapidly accelerating the filter plate or the cloth it supports. Think of trying to shake flour off a piece of paper. A slow tilt might not be enough, but a sharp, quick flick will dislodge it. The vibrator does this thousands of times per minute. The rapid acceleration and deceleration create inertial forces within the cake. The cake, having mass, wants to remain at rest, but the plate beneath it is moving violently. This differential movement shears the bonds of adhesion at the interface between the cake and the cloth. If the frequency of the vibration is tuned correctly, it can cause the entire cake to "dance" or fluidize slightly, breaking its grip and allowing gravity to take over. The goal is not to shake the entire press violently, but to introduce a high-frequency, low-amplitude vibration concentrated where it is needed most: at the surface of the cake.

Implementation on Filter Presses: Pneumatic and Electric Vibrators

There are two primary technologies used to generate this cake-releasing vibration in a filter press environment:

- Pneumatic Vibrators: These devices are often simple, robust, and powerful. A common type is the pneumatic piston vibrator. Compressed air is used to drive a piston back and forth within a casing. This linear movement creates a powerful, high-impact vibration. Another type is the turbine vibrator, where compressed air spins an unbalanced rotor at high speed, creating a smoother, high-frequency rotary vibration. These are typically mounted on a mechanism that makes contact with the filter plate lugs after the chamber is opened. They are favored in explosive or hazardous environments because they are intrinsically safe (no electrical sparks).

- Electric Vibrators: These use an electric motor to spin an eccentric, unbalanced weight. Like the pneumatic turbine vibrator, this creates a smooth, rotary vibration. Electric vibrators offer more precise control over frequency and amplitude, which can be advantageous for "tuning" the system to the specific properties of a cake. They can be integrated more easily into the press's PLC (Programmable Logic Controller), allowing for sophisticated sequences where the vibration might start, stop, and pulse to achieve the most effective discharge.

In a typical automated sequence, the plate shifter opens a chamber. A carriage-mounted vibrator then moves into position, presses against the filter plate, and activates for a pre-set duration (usually just a few seconds). The resulting shock is often enough to cause the entire cake to drop in one or two large pieces. The vibrator retracts, and the plate shifter moves to the next plate.

Table 1: Comparison of Discharge Automation Systems

| Feature | Plate Shifter | Vibrating Device | Cloth Movement | Air Blowback | Scraper/Breaker |

|---|---|---|---|---|---|

| Primary Function | Opens filter plates | Dislodges sticky cake | Actively peels cake off | Pushes cake off with air | Mechanically removes cake |

| Best For Cake Type | Non-sticky, brittle | Moderately sticky | Thin, flexible cakes | Most types, including moist | Very sticky, thick, hard |

| Cycle Time Reduction | Moderate | High | Very High | High | High |

| Initial Cost | Low to Medium | Medium | High | Medium to High | High |

| Maintenance | Low | Low to Medium | High | Medium | Medium to High |

| Energy Consumption | Low | Medium (Pneumatic) | Medium | High (Compressed Air) | Medium |

| Complexity | Low | Medium | High | Medium | High |

Advantages and Limitations: Sticky vs. Brittle Cakes

The primary advantage of a vibration system is its speed and effectiveness on a wide range of moderately sticky cakes. For materials that are just stubborn enough not to fall on their own, a short burst of vibration is a highly efficient solution. It adds only a few seconds to the discharge time for each plate, resulting in a dramatic reduction in the overall cycle time compared to manual scraping.

However, vibrators are not a universal solution. Their performance is highly dependent on the rheology of the filter cake.

- Limitations with Very Sticky or Clay-like Cakes: If a cake is extremely plastic, like a thick clay or sludge, vibration may not be effective. Instead of shearing cleanly from the cloth, the cake might simply deform and absorb the vibrational energy. In these cases, the vibration might make the cake wobble, but it won't fall.

- Risk with Very Brittle Cakes: Conversely, if a cake is very large, heavy, and brittle (like some mineral concentrates), a powerful vibration could potentially crack the filter plate itself. While modern polypropylene plates are incredibly durable, the repeated impact stress from a poorly configured vibrator is a valid concern that must be addressed through proper system design and control.

Therefore, the decision to implement a vibrating system requires a thoughtful analysis of the cake's properties. It is often necessary to conduct trials. Can you dislodge the cake in the lab by sharply tapping the filter cloth? If so, a vibrator is likely to be a good candidate. If the cake just oozes or sticks to your glove no matter what, you may need to consider a more direct mechanical approach. Automating filter cake discharge through vibration represents a sophisticated understanding of material science, applying targeted force to overcome the subtle physics of adhesion.

System 3: Automated Filter Cloth Movement Systems

When cakes are particularly thin, flexible, or have a tendency to blind the filter cloth, even powerful vibrations may not be enough to ensure a clean and complete discharge. In these situations, a more direct and active method is required. Enter automated filter cloth movement systems. These represent a paradigm shift from shaking the plate to moving the cloth itself, using the fabric as an active tool to peel the cake away.

The Belt Press Analogy: Continuous Discharge in a Batch Process

To understand the concept, it helps to think about a different type of filtration equipment: the belt filter press. In a belt press, slurry is dewatered between two continuously moving filter belts that pass over a series of rollers. At the end of the line, as the belts separate and bend around a final roller, the dewatered cake is peeled off the surface. Automated cloth movement systems adapt this continuous-discharge principle for use in a batch-process chamber filter press.

Instead of a cloth that is fixed to each individual plate, these systems use a long, continuous belt of filter cloth that zig-zags through the entire plate pack. The top and bottom of the cloth belt are connected to a drive and roller system located outside the plate pack. After the filtration cycle is complete and the plate shifter has opened all the chambers, this drive system is activated. The entire filter cloth belt begins to move.

How Cloth Belting and Shifting Works

As the cloth belt travels, it moves around a series of small-diameter rollers. When the section of cloth carrying a filter cake passes over one of these rollers, the sharp change in direction forces the cake to detach. The cake, being rigid, cannot make the sharp turn and effectively peels itself off the moving fabric. The discharged cakes fall into the collection area below, and a clean section of cloth moves into position, ready for the next filtration cycle.

This method is exceptionally effective for several reasons:

- Positive Peeling Action: It does not rely on gravity or vibration alone. It is a direct, mechanical peeling action that can dislodge even very thin and flexible cakes that would otherwise adhere stubbornly.

- Cloth Cleaning: As the cloth belt travels outside the press pack, it can be passed through a washing station. High-pressure water jets can spray the cloth to remove any fine particles that may be blinding the pores, ensuring optimal filtration performance on every cycle. This is a significant advantage over fixed cloths, which are much more difficult to clean thoroughly.

- Reduced Cake Cracking: In some processes, cracks can form in the filter cake during the final air-drying phase. These cracks can allow air to bypass the rest of the cake, resulting in uneven dewatering. Because the cloth is under slight tension, it can help prevent the formation of these cracks, leading to a drier, more uniform final product.

The entire process is a beautifully synchronized mechanical ballet. The press opens, the cloth drive engages, the belt moves, the cakes peel off in sequence, the cloth is washed, and the system is ready to close and begin again, all without manual intervention.

Maintenance and Longevity Concerns for Moving Cloths

The elegance of this system comes with an increase in mechanical complexity and, consequently, a different set of maintenance considerations. While a static filter cloth can last for thousands of cycles, a moving cloth belt is subjected to far more mechanical stress.

- Wear and Tear: The cloth is constantly in motion, passing over rollers and being subjected to tension. This leads to abrasive wear on the fabric itself. The selection of a highly durable, wear-resistant filter cloth material is paramount.

- Tracking and Alignment: Like any belt system, the filter cloth must be kept properly aligned or "tracked." If the belt wanders to one side, it can rub against the press frame or plates, causing premature damage. Sophisticated automatic tracking systems, similar to those on large conveyor belts, are essential for reliable, long-term operation.

- Roller and Bearing Maintenance: The numerous rollers, bearings, and the drive system itself are all moving parts that require regular inspection, lubrication, and eventual replacement. The maintenance schedule for a cloth-moving system is more intensive than for a press with static cloths.

The initial investment for a filter press equipped with an automated cloth discharge system is also higher due to the additional frame components, rollers, drive motors, and control systems. However, for the right application, the benefits can far outweigh these costs.

Application Spotlight: Wastewater Treatment in European Municipalities

Consider a large municipal wastewater treatment plant in Germany. The sludge produced from the biological treatment process is notoriously difficult to dewater. It forms a thin, slimy, and extremely sticky filter cake. For years, the plant used standard chamber filter presses and dedicated significant labor resources to manually scraping the cakes, a slow and unpleasant task. The dewatering building was a major operational headache.

The plant invested in new filter presses equipped with automated cloth belt discharge systems. The results were transformative. The discharge cycle, which previously took two operators nearly an hour, became a fully automated 10-minute process supervised by a single operator from a control room. The positive peeling action of the moving cloth was perfectly suited to the slimy sludge cake. The integrated cloth washing station kept the filter medium in pristine condition, improving dewatering efficiency and consistency. The plant was able to process a higher volume of sludge with less labor, lower operational costs, and a vastly improved working environment. This application is a textbook example of where the sophistication and higher cost of a cloth movement system provide an undeniable and rapid return on investment.

System 4: Air-Assisted and Blowback Systems

In our exploration of automating filter cake discharge, we have examined mechanical solutions: shifters that move plates, vibrators that shake them, and drives that move the cloth itself. Now, we turn our attention to a different medium of force: compressed air. Air-assisted and blowback systems use pneumatic power to push, peel, or even shatter the filter cake away from the cloth, offering a fast, non-contact method of discharge.

The Power of Compressed Air: A Forceful Separation

The principle behind an air blowback system is simple yet powerful. After the filtration and any optional cake-drying phases are complete, but before the plates are separated, a burst of compressed air is injected into the filter chamber from the filtrate side. The air travels through the drainage ports of the filter plate and permeates the filter cloth from behind.

This creates a sudden, high-pressure bubble of air between the cloth and the filter cake. This pressure exerts a uniform force across the entire surface of the cake, pushing it away from the cloth. In many cases, this action is enough to break the adhesive bond completely. Then, when the plate shifter opens the chamber, the loosened cake falls out immediately. It's analogous to using a puff of air to get a stubborn piece of paper out of a tight envelope—the air creates the initial separation that allows for easy removal.

Some more advanced systems, often called "air-assist," may use a lower volume of air continuously as the plate is opening, creating a gentle "air knife" effect that peels the cake away from the cloth as the chamber widens.

Designing the System: Nozzles, Manifolds, and Control Logic

A successful air blowback system requires more than just connecting an air line to the press. It demands careful engineering to be effective and efficient.

- Manifold and Valve System: A dedicated air manifold must be connected to the filtrate outlet ports of the filter press. This manifold is fitted with high-speed, heavy-duty valves that can deliver a large volume of air in a very short period—a "pulse." The PLC of the press controls these valves, timing the air blast precisely within the cycle.

- Plate and Cloth Design: The filter plate's drainage design must allow for the even distribution of the blowback air across the entire surface of the cloth. If the air channels are poorly designed, the air might only lift one section of the cake, leaving the rest stuck. The filter cloth must also have the correct permeability; if it's too tight, the air can't pass through effectively, and if it's too open, the air will just vent without building up the necessary pressure.

- Control System Integration: The timing, pressure, and duration of the air blast are critical variables. The control system must be programmed to deliver the optimal "recipe" for the specific cake being produced. For example, a short, high-pressure blast might be best for a hard, brittle cake, while a longer, lower-pressure pulse might be better for a softer, more pliable one. This level of control is essential for automating filter cake discharge reliably.

Table 2: Simplified Cost-Benefit Analysis of Automation Technologies

| Technology | Initial Investment | Labor Savings | Cycle Time Savings | Maintenance Impact | Energy Cost Impact | Ideal ROI Scenario |

|---|---|---|---|---|---|---|

| Plate Shifter | Low | High | Moderate | Low | Very Low | High-volume ops with non-sticky cake |

| Vibrator | Medium | Very High | High | Low | Low-Medium | Moderately sticky cakes, frequent cycles |

| Cloth Movement | High | Very High | Very High | High | Medium | Very sticky/thin cakes, need for cloth washing |

| Air Blowback | Medium | Very High | High | Low | High | Moist cakes, need for very dry product |

| Scraper/Breaker | High | Very High | High | Medium | Medium | Extremely tenacious, hard, or large cakes |

Safety and Energy Consumption Considerations

While powerful, the use of high-pressure compressed air introduces two important operational considerations: safety and energy cost.

From a safety perspective, the filter press must be fully closed and clamped during the blowback phase. Opening a press while the chambers are pressurized would be extremely dangerous. Modern press control systems have interlocks that make this impossible, but it underscores the need for a properly designed and maintained safety circuit. Additionally, the sudden release of pressure can be loud, and appropriate acoustic shielding or hearing protection for personnel in the vicinity may be necessary.

The most significant operational drawback of air blowback systems is their energy consumption. Compressing air is an energy-intensive process. In fact, it is often one of the most expensive utilities in an industrial plant. Using large volumes of compressed air for every cycle can add a substantial amount to a facility's electricity bill. Therefore, a thorough cost-benefit analysis is essential. The savings in labor and increased throughput from faster dewatering cycles must be weighed against the increased energy expenditure. In many cases, the economic benefits are clear, but they should not be taken for granted. For this reason, optimizing the air blowback—using the lowest pressure and shortest duration necessary to get the job done—is key to running an efficient system.

Despite these considerations, air blowback remains a very popular and effective method for automating filter cake discharge. It is fast, requires relatively few moving parts compared to cloth or scraper systems, and can be remarkably effective on a wide variety of cake types, particularly those that retain a moderate amount of moisture.

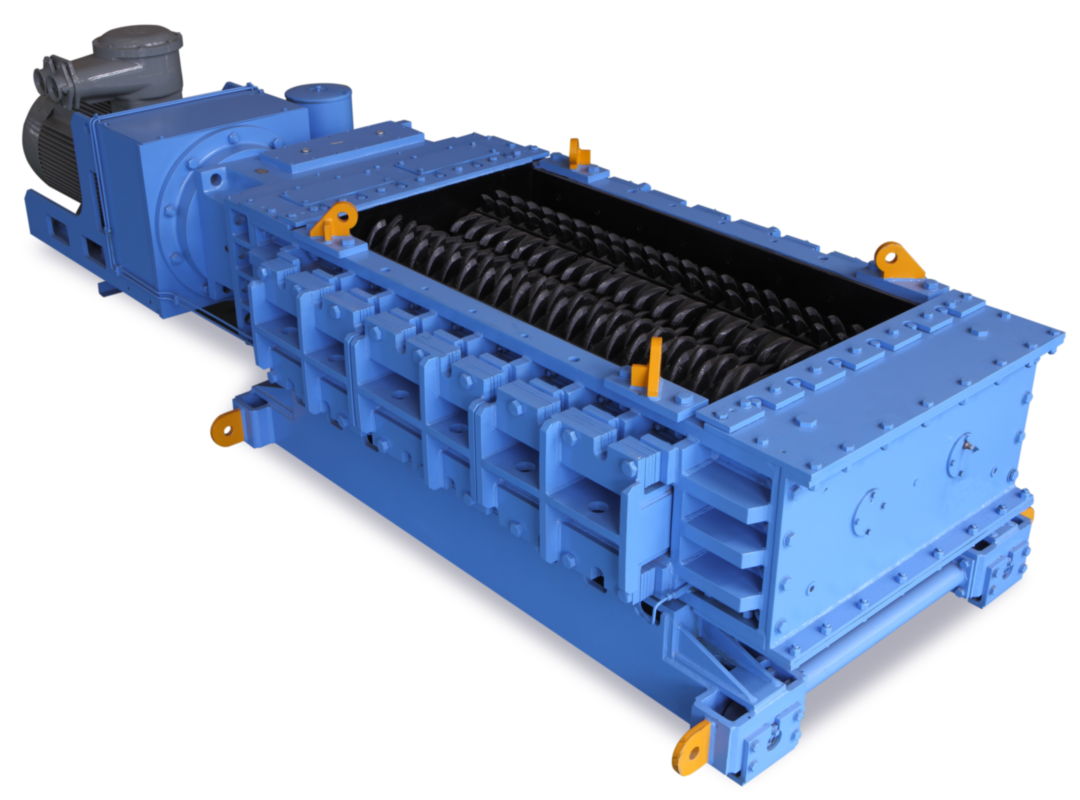

System 5: Integrated Cake Scrapers and Breakers

We have now arrived at the most direct and physically assertive method for automating filter cake discharge: the use of integrated scrapers and breakers. When a filter cake is so sticky, so thick, or so hard that even vibrations and air pressure are insufficient to dislodge it, a mechanical system that physically scrapes the cake from the cloth is the ultimate solution. This approach essentially automates the exact action that a human operator performs with a spatula.

Mechanical Intervention: The Role of a Scraper

The concept is straightforward. A device equipped with a blade or a set of tines is moved across the surface of the filter cloth after the press has opened, mechanically forcing the cake to separate. This is not a subtle persuasion; it is a direct intervention. These systems are designed for the most challenging applications where other automation methods fail.

The scraper mechanism is typically mounted on a carriage that travels along the top or side of the filter press. In a common design, after the plate shifter opens a chamber, the scraper carriage moves into the gap between the two plates. The scraper blade then lowers and travels down the face of the filter cloth, peeling or pushing the cake off. Once it reaches the bottom, the blade retracts, the carriage moves out of the way, and the plate shifter proceeds to the next chamber. The entire sequence is a complex, multi-axis motion that requires precise control and robust engineering.

From Manual Tools to Automated Blades

The evolution from a manual spatula to an automated scraper system involves significant engineering. The blade itself must be made of a material that is strong enough to cut through the cake but soft enough that it does not damage the filter cloth. Materials like UHMW (Ultra-High Molecular Weight) polyethylene or hard rubber are common choices.

The system must also be able to adapt to variations. Filter plates can sometimes warp slightly over time, and the cake thickness may not be perfectly uniform. A good scraper system will have a flexible or spring-loaded mounting for the blade, allowing it to maintain a consistent pressure against the cloth surface without gouging it. Advanced systems may even use sensors to detect the cake's presence and adjust the scraper's path or pressure accordingly.

For extremely large, thick, or hard cakes, a simple scraper may not be enough. In these cases, a heavy-duty cake breaker might be employed. This is a more aggressive system, often involving a rotating bar with multiple "fingers" or hammers that actively fracture the cake into smaller, manageable pieces as it is being discharged. This is particularly useful when the discharged cake needs to be fed into a screw conveyor or a hopper, as large, solid slabs of cake can cause blockages.

The Synergy with Conveyors: Creating a Fully Autonomous System

An automated scraper or breaker system is rarely a standalone solution. It is the final piece of a fully autonomous discharge process. The typical workflow is as follows:

- Plate Shifting: The automated plate shifter opens the first filter chamber.

- Scraping/Breaking: The scraper/breaker mechanism moves into position and dislodges the cake from the cloth.

- Cake Collection: The dislodged cake or cake pieces fall directly onto a conveyor belt (or into a screw conveyor) positioned underneath the filter press.

- Material Transport: The conveyor transports the cake away from the press area to a larger storage bin, a truck, or the next stage of the process.

- Sequencing: The plate shifter, scraper, and conveyor are all controlled by a central PLC that synchronizes their actions perfectly, moving from one plate to the next until the entire press is empty.

This level of integration creates a "lights-out" operation for the discharge cycle. No operator is required to be physically present. They can monitor the process from a control room, freeing them up to perform more valuable tasks like preparing the next batch of slurry, conducting quality control checks, or managing other parts of the plant. This represents the pinnacle of automating filter cake discharge.

The primary drawbacks of such a system are its high initial cost and mechanical complexity. It has many moving parts, requires precise alignment, and has a more demanding maintenance schedule than simpler systems. However, for industries dealing with the most difficult materials—such as certain types of mineral tailings, industrial sludges, or chemical precipitates—the investment is often justified by the complete elimination of manual labor, the maximization of press uptime, and the creation of a much safer operating environment. The choice to implement a scraper is a testament to the fact that for every challenging filtration problem, a dedicated engineering solution exists.

Selecting the Optimal Automation Strategy for Your Operation

Choosing the right system for automating filter cake discharge is not a one-size-fits-all decision. It is a nuanced process that requires a deep understanding of your specific material, your operational goals, and your financial constraints. It is an exercise in matching the right tool to the right job. Investing in a highly complex scraper system for a cake that falls off on its own is wasteful, just as installing a simple plate shifter for a cake as sticky as tar is ineffective. A thoughtful, analytical approach is essential.

Analyzing Your Slurry and Cake Characteristics

The single most important factor in your decision is the nature of your filter cake. You must become an expert on its properties. This goes beyond simply labeling it "sticky" or "dry." Consider conducting a systematic analysis:

- Adhesion: How strongly does it stick to the filter cloth? Can it be dislodged with a light tap, or does it require a firm scrape? You can test this manually on your existing press.

- Cohesion and Brittleness: Does the cake hold together as a single slab, or does it crumble easily? A cohesive cake is easier for a scraper to remove in one piece, while a brittle cake might respond well to vibration.

- Moisture Content: What is the final moisture percentage? Higher moisture often correlates with higher adhesion. An air blowback system can be particularly effective on moist cakes, as it helps to expel some of that last-bit moisture during discharge.

- Thickness and Weight: A very thick, heavy cake might damage a delicate cloth movement system but is easily handled by a robust scraper. A thin cake might not have enough mass to fall on its own, making a positive peeling action from a cloth belt or scraper necessary.

- Plasticity vs. Rigidity: Is the cake pliable like clay, or is it rigid like a ceramic plate? A plastic cake will absorb vibrational energy, rendering that method useless, and points toward a scraping or cloth-moving solution.

Thinking through these properties will allow you to immediately narrow down your options. For instance, a highly plastic and adhesive sludge from a biological process immediately suggests that cloth movement or scraping systems are the most promising candidates, while a granular, crystalline product points toward plate shifters and perhaps vibrators.

Calculating the Return on Investment (ROI)

Automating filter cake discharge is a capital investment, and it must be financially justifiable. A thorough ROI calculation is not just good practice; it is a necessary step to get project approval. Your calculation should include:

- Labor Savings: Calculate the fully-loaded cost (wages, benefits, overhead) of the operators who are currently dedicated to manual discharge. How many labor hours per day will be eliminated?

- Increased Throughput: This is often the largest financial benefit. Calculate the value of the extra product you can produce by shortening the cycle time. If you can run one extra cycle per press per day, what is the market value of that additional output?

- Reduced Maintenance: While the automation system itself requires maintenance, consider the reduced wear and tear on filter cloths from eliminating manual scraping with sharp tools. Damage to cloths can be a significant operational cost.

- Safety and Ergonomics: While harder to quantify, the financial impact of reducing workplace injuries is real. Consider the potential costs of lost time, medical expenses, and insurance premiums associated with musculoskeletal disorders from manual labor.

- Initial Cost: Get firm quotes for the equipment, installation, and commissioning of the proposed automation system.

- Operating Costs: Factor in the ongoing costs, such as the electricity for motors or the energy to produce compressed air for a blowback system.

By comparing the total financial benefits to the total costs, you can calculate a payback period. For many industrial filtration applications, the ROI on a well-chosen automation system is surprisingly rapid, often falling within 12 to 24 months. For particularly difficult applications, a solution like an integrated cake removal system can pay for itself even faster by solving a major production bottleneck.

Integration with Existing DCS and SCADA Systems

Modern plants are run by sophisticated Distributed Control Systems (DCS) or Supervisory Control and Data Acquisition (SCADA) systems. Any new automation equipment must be able to communicate seamlessly with this existing infrastructure. When evaluating potential suppliers, this is a critical line of questioning.

Does the automation system's PLC use a standard communication protocol like EtherNet/IP, ProfiNet, or Modbus TCP/IP? Can it provide real-time feedback to the main control room, showing the status of the discharge cycle, current plate position, and any fault conditions? Can the discharge sequence parameters (e.g., vibration time, air pressure) be adjusted from the central HMI (Human-Machine Interface)?

A system that operates as an isolated "black box" is far less valuable than one that is fully integrated. Integration allows for centralized control, better data collection for process optimization, and more efficient troubleshooting. Ensure your chosen partner has a proven track record of integrating their equipment into complex plant control architectures.

Future-Proofing Your Filtration Process

Finally, think about the future. Is your production rate likely to increase? Might the characteristics of your slurry change over time due to different raw materials or upstream process adjustments? Selecting a system with a degree of flexibility is a wise strategy.

Perhaps a system with an adjustable vibration frequency or a programmable air blowback sequence is preferable to a fixed system. Choosing a robust plate shifter that can later have a vibrator or scraper added to it might be a prudent phased approach to investment. The goal is to select a solution that not only solves today's problem but also provides a platform for meeting the challenges of tomorrow. Automating filter cake discharge is not just an equipment upgrade; it is a strategic decision that positions your operation for greater efficiency, safety, and profitability for years to come.

Frequently Asked Questions (FAQ)

1. What is the biggest advantage of automating filter cake discharge? The primary advantage is a dramatic reduction in the filter press cycle time. By eliminating the slow, manual process of cake removal, plants can significantly increase their throughput and overall productivity without investing in additional presses. This leads directly to higher output and lower per-unit production costs.

2. How do I know if my filter cake is "sticky" enough to need automation beyond a plate shifter? A simple field test is to open one chamber of your press. If the cake does not fall out under its own weight or with a light tap on the plate, it is considered sticky. If it requires a tool to be scraped or pried off the cloth, you will benefit significantly from a more advanced automation system like a vibrator, air blowback, or scraper.

3. Can an old, manual filter press be retrofitted with an automatic discharge system? Yes, in many cases. Automated plate shifters, vibrators, and air blowback systems can often be retrofitted onto existing filter presses. The feasibility depends on the press's design, particularly the side-rail construction and plate handles. A full cloth-moving or scraper system is more complex and may require a new press designed for that purpose. It is best to consult with an equipment manufacturer for an expert evaluation.

4. Does automating the discharge process increase maintenance costs? It changes the nature of the maintenance required. You will trade the cost of replacing frequently damaged filter cloths (from manual scraping) for the scheduled maintenance of mechanical and electrical components like motors, bearings, and valves. While there is a new maintenance requirement, a well-designed automation system is generally reliable, and its costs are far outweighed by the savings in labor and increased production.

5. Which automation system uses the most energy? Generally, air-assisted and blowback systems have the highest energy consumption due to the high cost of generating compressed air. Systems based on electric motors, like plate shifters and vibrators, are typically more energy-efficient. The overall energy cost must be factored into the return on investment calculation when choosing a system.

6. Is a fully robotic system better than a dedicated mechanical system? Not necessarily. While a robotic arm offers the most flexibility, it also comes with the highest initial cost and programming complexity. For a dedicated, repetitive task like discharging a filter press, a purpose-built mechanical system (like a plate shifter combined with a vibrator) is often more cost-effective, faster, and easier to maintain for that specific application.

7. How does automation improve operator safety? It improves safety immensely by removing the operator from the most hazardous parts of the job. Automation eliminates the need for manual handling of heavy plates, reduces the risk of repetitive strain injuries from scraping, and minimizes operator exposure to potentially harmful chemical or biological materials in the cake.

Conclusion

The journey from a manually operated filter press to a fully autonomous filtration station represents a fundamental shift in industrial processing philosophy. It is a move away from reliance on arduous human labor and toward the precision, speed, and reliability of well-engineered systems. We have seen that automating filter cake discharge is not a single action but a spectrum of solutions, each tailored to solve a specific set of challenges.

The simple, robust plate shifter lays the groundwork, mechanizing the most basic step. Vibrating devices and air blowback systems offer elegant, rapid solutions for moderately adhesive cakes, using physics to overcome the forces of adhesion. For the most demanding applications, cloth movement and mechanical scraper systems provide a direct, positive discharge action, ensuring a clean release every time.

The selection of the appropriate technology is an exercise in careful inquiry, demanding a deep analysis of the cake's physical properties, a clear-eyed calculation of economic returns, and a strategic vision for plant integration. The initial investment in automation is repaid not only in quantifiable metrics like reduced cycle times and increased throughput but also in the less tangible, yet equally valuable, currency of improved operator safety, morale, and process consistency. In the competitive landscape of 2025, embracing the automation of this critical process step is no longer a matter of choice, but a defining characteristic of an efficient, modern, and forward-thinking operation.

References

Anlauf, H. (2025). Wet cake filtration: Fundamentals, equipment, and strategies. Wiley-VCH.

Casadio, L. (2024, October 24). Filter press filtration process: Key steps explained. Diemme Filtration. https://www.diemmefiltration.com/blog/filter-press-filtration-process-key-steps-explained/

Latham International. (2024, June). Cake washing – A decisive step for filtration processes.

Lee, S. (2025, June 10). Mastering cake filtration techniques. Number Analytics.

Mazzeo, S. (2024, November 14). Cake filtration: A clever filtration technology for the finest particles. FAUDI. https://faudi.de/en/blog/filtration-knowledge/cake-filtration-a-clever-filtration-technology-for-fine-particles

MissRifka. (2022, June 21). Many types of cake filters. https://missrifka.com/equipments/filtration/many-types-of-cake-filters.html

MSE Filterpressen. (2021, February 15). Filtration process of a filter press.