This article presents an in-depth exploration of the belt filter press, a highly efficient solution for solid-liquid separation. It discusses the working principle, key benefits, and applications of the belt filter press. Whether it’s dewatering or sludge treatment.

Introduction

In the field of solid-liquid separation, the belt filter press has emerged as a highly efficient solution. With its advanced filtration technology and robust design, the press offers numerous advantages for industries across various sectors.

This article provides a comprehensive overview of the filter press, its working principle, key benefits, and applications, highlighting its significance in achieving effective dewatering and sludge treatment.

Working Principle of Belt Filter Press

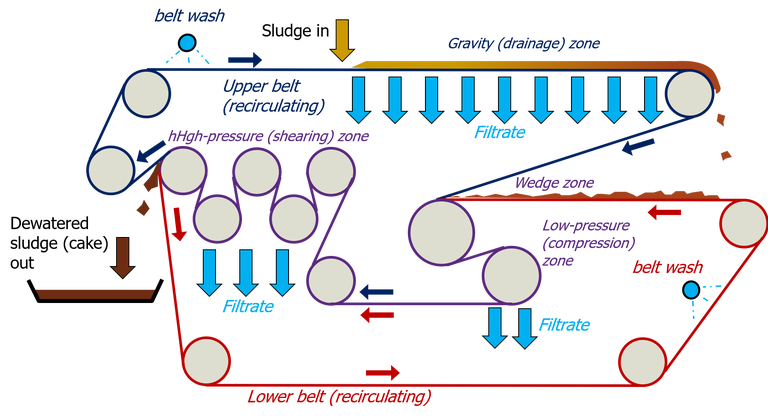

The filter press operates through a continuous filtration process. A slurry mixture is fed onto a series of porous belts that pass through various stages.

The belts then undergo compression to further remove moisture, resulting in a drier cake. This efficient process ensures effective separation and maximizes the dewatering efficiency of the filter press.

Key Benefits of Belt Filter Press

- High Efficiency: The filter press offers a high throughput capacity, enabling rapid and continuous solid-liquid separation.

- Optimal Dewatering: By applying increasing pressure on the sludge, this production achieves maximum moisture removal, resulting in a drier sludge cake.

- Low Operating Costs: The press requires minimal energy consumption and maintenance, making it a cost-effective solution for solid-liquid separation.

- Versatility: With adjustable belt speed and tension, the press accommodates a wide range of feed materials and operating conditions.

- Compact Design: The compact footprint of the press saves valuable space in industrial facilities, while its modular construction allows for easy expansion and customization.

Applications of Belt Filter Press

The belt filter press finds extensive applications in various industries, including:

- Wastewater Treatment: This production efficiently removes moisture from wastewater sludge, reducing volume and facilitating disposal or further treatment.

- Mining and Mineral Processing: The filter press is utilized for dewatering tailings, concentrates, and other mining slurries, minimizing water usage and maximizing resource recovery.

- Chemical Industry: Belt filter presses play a crucial role in separating solids from chemical processes, ensuring efficient product recovery and waste management.

- Food and Beverage: The press aids in dewatering food and beverage processing by-products, reducing waste volume, and supporting sustainable practices.

- Pharmaceuticals: This filter press assists in the separation of solids from pharmaceutical processes, meeting stringent quality and regulatory requirements.

- Municipal Solid Waste: The filter press is employed for dewatering and volume reduction of solid waste, facilitating landfill disposal or resource recovery.

Conclusion

In summary, the press revolutionizes solid-liquid separation processes with its efficient filtration technology, cost-effectiveness, and versatility. Whether it’s wastewater treatment, mining, chemical processing, or other industries.

The belt filter press offers a reliable solution for achieving optimal dewatering and sludge management. Streamline your solid-liquid separation processes with the press and experience enhanced productivity and sustainability.