Automatic filter press is a highly efficient filtration system that uses advanced technology to streamline the filtration process. With its automatic operation, it reduces the need for manual labor and increases productivity. This article explores the benefits of using an automatic filter press, its applications, and how it works.

Introduction

Automatic filter presses are filtration systems that use pressure to separate solids from liquids. They can applicate in industries such as mining, chemical, and wastewater treatment. The automatic filter press operates on a continuous cycle, reducing the need for manual labor and increasing productivity.

Benefits of Using an Automatic Filter Press

One of the main benefits of using a filter press is its efficiency. The system can operate continuously, reducing downtime and increasing productivity. In addition, it requires minimal operator intervention, reducing the need for manual labor. Automatic filter presses are also highly customizable, allowing them to tailor to specific filtration requirements.

Applications of Automatic Filter Press

Automatic filter presses are popular in a wide range of industries, including mining, chemical, and wastewater treatment. In the mining industry, automatic filter presses can applicate to separate valuable minerals from the surrounding ore. In the chemical industry, they play an important role in separating solids from liquids in the production process. In wastewater treatment, automatic filter presses also can remove solids from the wastewater before its discharges into the environment.

How Automatic Filter Press Works

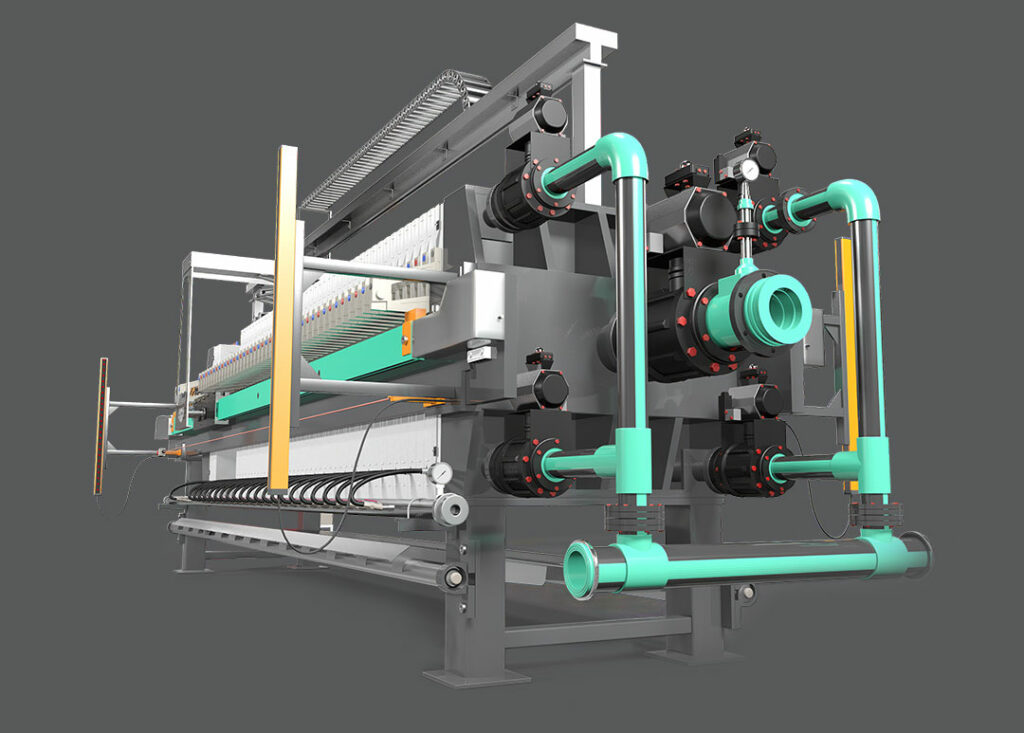

This type of filter press works by applying pressure to a slurry of solids and liquids. The slurry is fed into the press, and the solids are separated from the liquid by a filter cloth. The pressure forces the liquid through the cloth, leaving the solids behind. The solids then can remove from the press, and the cycle can begin again.

Example of Automatic Filter Press in Action

In the mining industry, the filter press applicate to separate valuable minerals from the surrounding ore. The slurry of solids and liquids is fed into the press, and the pressure forces the liquid through the filter cloth, leaving the valuable minerals behind. The solids are then removed from the press, and the valuable minerals are extracted.

The manufacturing process of the automatic filter press

The manufacturing process of an automatic filter press involves several steps, including design, fabrication, assembly, and testing. Here is a brief overview of each step:

- Design: The first step in manufacturing the filter press is to design the system. The design process involves determining the size and capacity of the press, as well as the materials and components needed to construct it.

- Fabrication: Once the design is complete, the next step is to fabricate the individual components of the press. This involves cutting, welding, and machining the various metal parts, such as the frame, plates, and hydraulic system.

- Assembly: After the individual components fabricating, they can assemble into the final product. This involves fitting the parts together, connecting the hydraulic system, and installing the filter plates and cloth.

- Testing: Once the press assembles, it undergoes rigorous testing to ensure that it operates correctly and meets the required performance specifications. This includes testing the hydraulic system, checking for leaks, and verifying the pressure capacity.

Overall, the manufacturing process of an automatic filter press requires a high level of precision and attention to detail to ensure that the final product is reliable and efficient. By following strict quality control measures throughout the process, manufacturers can produce filter presses that meet the needs of a wide range of industries, from mining and chemical processing to wastewater treatment and beyond.

Conclusion

In conclusion, the automatic filter press is a highly efficient filtration system that can streamline the filtration process. Its automatic operation reduces the need for manual labor and increases productivity. Automatic filter presses play an important role in a wide range of industries, including mining, chemical, and wastewater treatment, and are highly customizable to meet specific filtration requirements. By using an automatic filter press, businesses can improve their filtration process and increase their bottom line.