In the fast-changing field of wastewater management, filter presses have become essential for sludge dewatering. As environmental laws get stricter and industries aim for greener options, knowing the latest in filter press technology is key. This guide explores what makes modern filter presses better, more dependable, and cost-effective, aiding you in selecting the right supplier.

What’s a Filter Press, and Why Does It Matter?

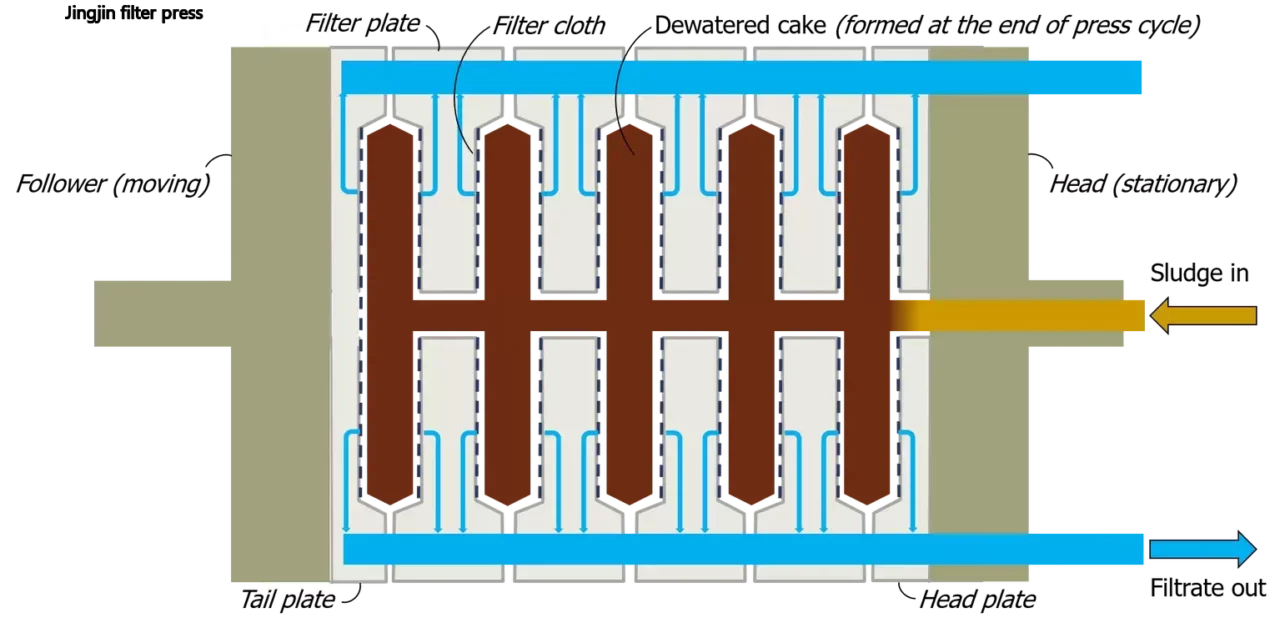

A filter press separates liquids from solids in wastewater sludge. By applying high pressure, it squeezes water out, leaving solid cakes easier to manage and dispose of. This reduces waste volume, disposal costs, and environmental impact.

In 2025, the need for advanced filter presses grows due to tighter environmental rules and the quest for efficient solutions.

Key Features of Today’s Filter Presses

Modern filter presses come with features that boost performance, cut costs, and improve user experience. Here are top features:

- They Operate Automatically Automation cuts down manual work, saving time and labor costs. Programmable controllers ensure steady performance and reduce errors.

- They Handle High Pressure Advanced models work at higher pressures for drier cakes and superior dewatering. This minimizes waste volume and lowers disposal expenses.

- They Save Energy Newer designs consume less power, benefiting the environment and your wallet. Seek energy-efficient pumps and motors when choosing a supplier.

- Built to Last Plates made from polypropylene or stainless steel resist corrosion and last longer. These materials withstand harsh chemicals and abrasive sludge.

- Easy to Maintain Modular designs and self-cleaning systems simplify upkeep and reduce downtime. Quick-release plate systems make replacements swift and convenient.

- Customizable Suppliers offer tailored options to fit specific industry needs, like different plate sizes or frame designs. This flexibility ensures optimal performance for various sludges.

How to Choose the Right Supplier

Picking the right filter press supplier is vital for getting equipment that fits your needs. Consider these tips:

- Experience Matters: Select suppliers with proven industry success. Ask About Support: Ensure they provide comprehensive after-sales service.

- Look for Flexibility: Choose suppliers who customize machines to your requirements.

- Check Warranties: Opt for those offering robust warranties and service plans.

Benefits of Upgrading

Investing in an advanced filter press brings benefits such as:

- Lower Costs: Reduced energy use and disposal fees.

- Better Efficiency: Faster cycles and higher output.

- Meets Regulations: Complies with strict environmental standards.

- Durability: Longer life and less maintenance needed.

As wastewater treatment becomes more regulated, the filter press machine plays a critical role in sludge dewatering. Understanding modern filter press machine features and partnering with a reliable supplier can greatly enhance operations while complying with environmental laws. Whether upgrading or buying new, 2025’s advancements in filter press machine technology promise efficiency, sustainability, and savings.

Upgrade your wastewater system now and see how a high-quality filter press can transform your process!